Table of contents

Is your pallet jack not lifting? This is likely because you haven’t let the air out from inside the pallet truck itself. This process of releasing air from the internal hydraulic system is called “bleeding” and it’s a vital part of pallet jack maintenance. It’s easy to do yourself if your appliance isn’t electronic. You can learn how to bleed a pallet jack as well as what to look out for and the reasons behind it in this guide.

Why should you bleed a pallet jack?

Pallet trucks operate using hydraulics. The pump piston is activated by moving the tow bar up and down, causing pressure to build up within the hydraulic system. This fluid then compresses into the tubes and lifts the pallet with every crank.

Despite great care taken in construction, air can still seep into the hydraulics system. This is often caused by improper handling, such as tilting the pallet jack at an angle. When air gets into the system, it stops the hydraulics from working and the pallet jack won’t lift as a result. If you find your pallet truck doesn’t work, there’s probably air in the hydraulics system.

Attention: Take care when operating pallet jacks. Avoid tilting it or setting it down at an angle, as this can cause air to find its way inside the hydraulics. A pallet truck that’s not lifting likely has too much air inside.

Instruction guide: How to bleed a pallet jack

If the forks on your pallet truck are not lifting, there’s likely air in the hydraulics system. Luckily, you don’t need to contact a specialist to repair the pallet truck. Simply read the following instructions to learn how to fix a pallet jack that’s not lifting:

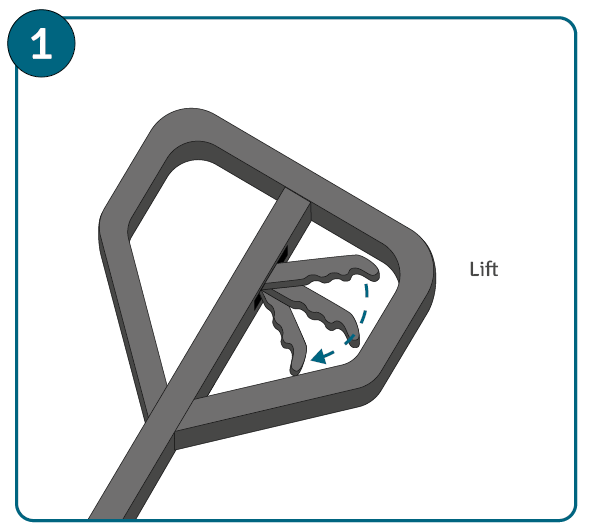

- Unload the pallet jack and prepare to pump it

Make sure that there’s nothing on the pallet jack, then set the operating lever to the “lift” position.

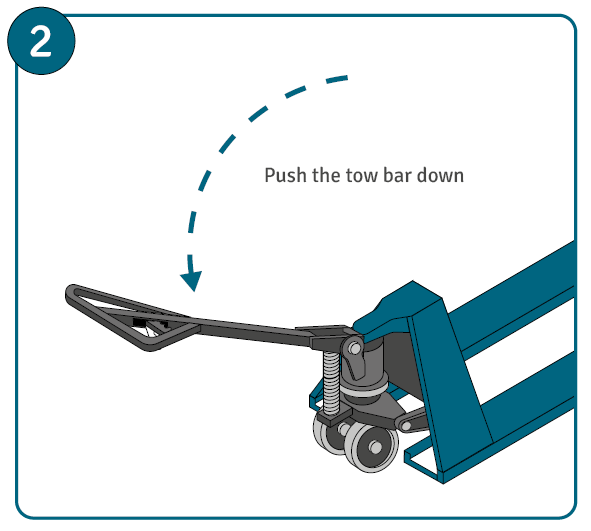

Make sure that there’s nothing on the pallet jack, then set the operating lever to the “lift” position. - Bring the tow bar down

Push the tow bar down completely until it comes to a stop.

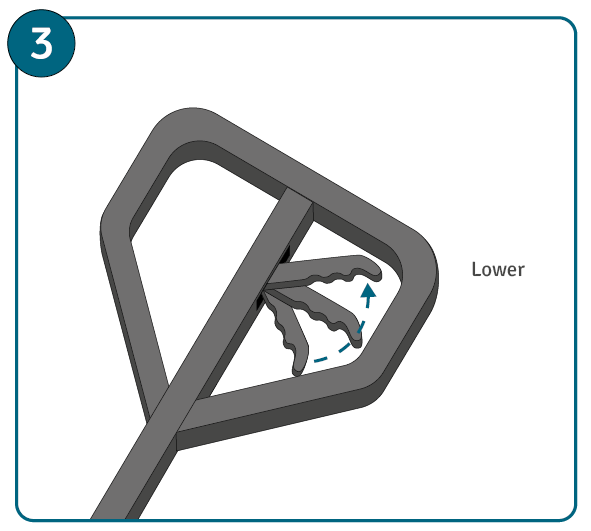

Push the tow bar down completely until it comes to a stop. - Lower the pallet jack

Standing behind the tow bar, set the operating lever to the “lower” position.

Standing behind the tow bar, set the operating lever to the “lower” position.

Caution: Do not loosen or remove the oil cap. - Repeat the process

: Repeat the first three steps several times.

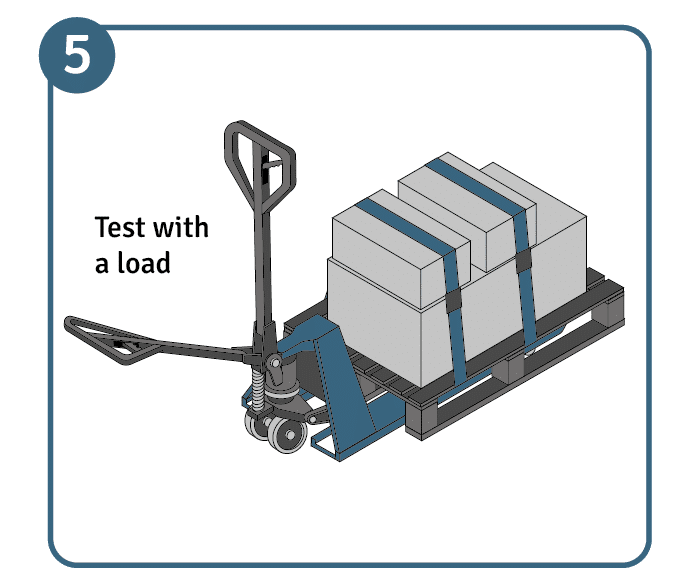

- Test the pallet jack with a load

Load up the pallet jack and try pumping to test if it works.

Load up the pallet jack and try pumping to test if it works. - If this doesn’t work

If the pallet jack still doesn’t work even after bleeding, set the lowering valve to its lowest setting and remove the oil cap to check the oil level.

FAQs for bleeding a pallet jack

Bleeding (releasing air from) a pallet jack is necessary because air can get into the hydraulics system, causing the device to malfunction. By bleeding the pallet jack, you can easily repair the hydraulics yourself.

If the forks still don’t lower on your pallet jack even after bleeding, you should see a specialist. Don’t try and fix it yourself.

Air can enter the hydraulics in a pallet jack due to improper handling or mistreatment. You should avoid tilting the pallet truck or setting it down in an angled position.

Image source:

© Jungheinrich AG