Table of contents

For a pallet jack to function correctly, it needs to have a certain amount of oil topped up. Otherwise, you may encounter problems if the oil level is too low. If the forks cannot be properly lowered, for instance, there may be insufficient oil in the system. As such, you should regularly check the oil level in your pallet jack and top it up where necessary.

Just like with other routine maintenance work, such as replacing the pallet truck steering wheel and bleeding the pallet jack, you don’t need to visit a specialist workshop. Most pallet truck repairs can be done yourself. To refill your pallet jack oil yourself, simply follow our instructions below. They’ll tell you what to look out for, the tools you need and how to proceed with topping up the oil level.

Top up your pallet truck oil in seven steps

If the oil level is too low on your pallet jack, use the following instructions to refill it correctly:

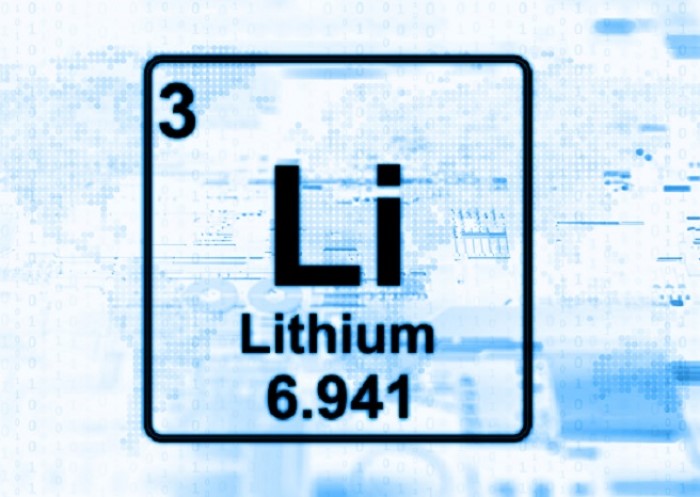

- Use the correct equipment

For the process, you’ll need a slotted screwdriver and oil that’s appropriate for your specific pallet jack. Always use the same oil that’s already in the hydraulic system – check the operating manual for this information if you haven’t done it before. If you’re using a pallet jack in cold areas, you may need a special type of oil.

For the process, you’ll need a slotted screwdriver and oil that’s appropriate for your specific pallet jack. Always use the same oil that’s already in the hydraulic system – check the operating manual for this information if you haven’t done it before. If you’re using a pallet jack in cold areas, you may need a special type of oil. - Lower the pallet jack

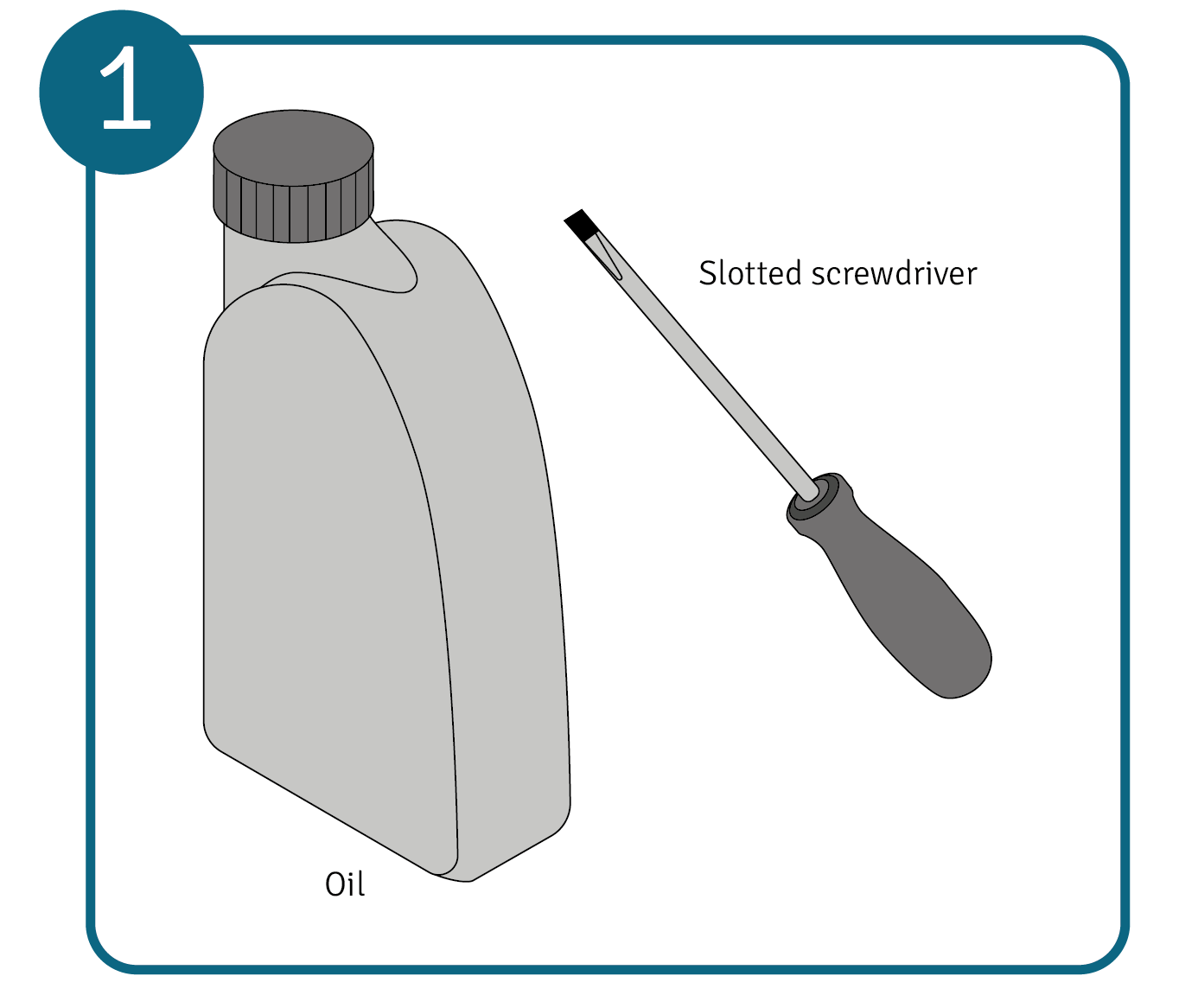

Make sure the pallet jack is on a hard, flat surface. Lower the forks completely and move the operating lever to the “lower” position.

Make sure the pallet jack is on a hard, flat surface. Lower the forks completely and move the operating lever to the “lower” position. - Remove the screw

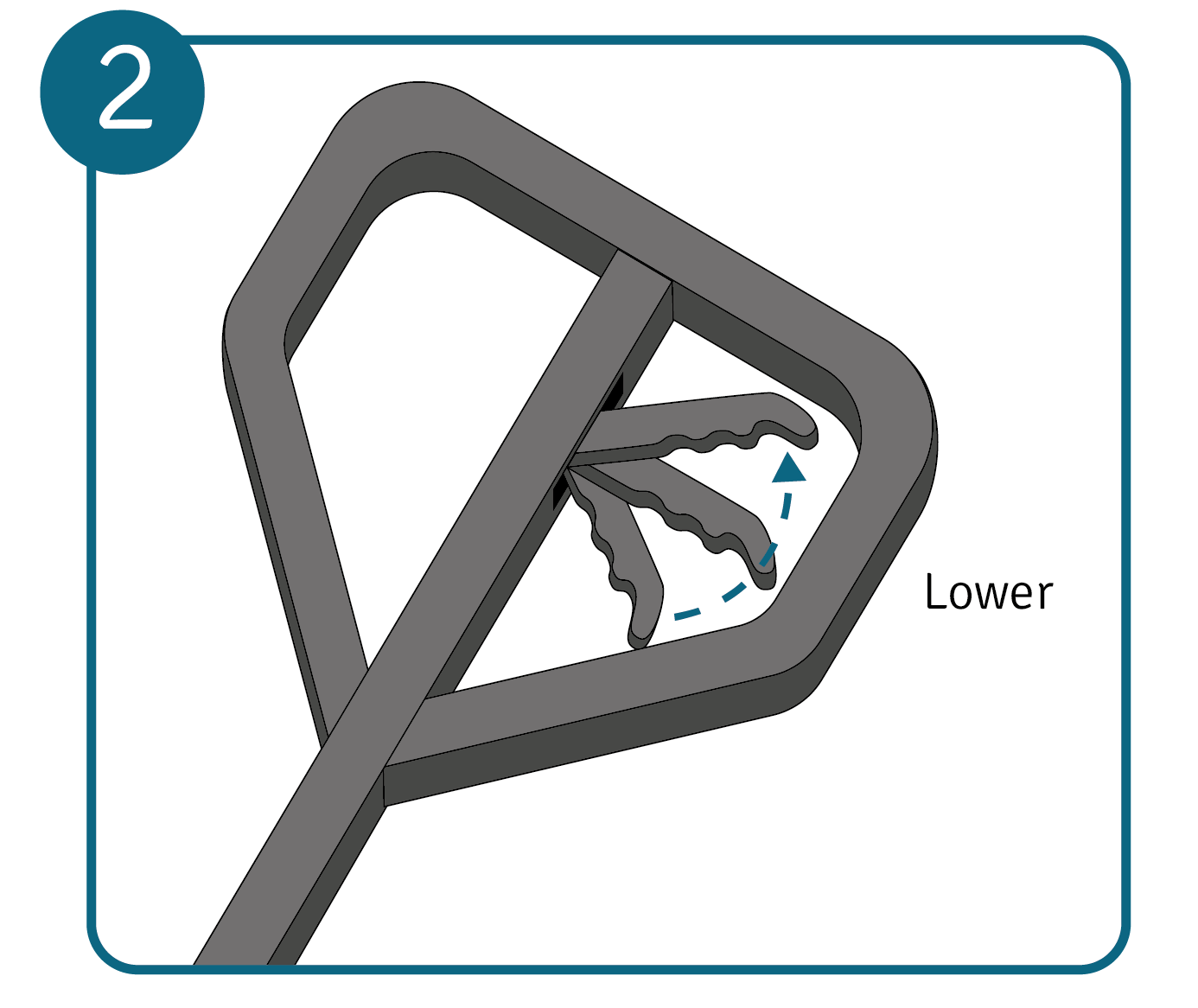

Remove the screw that holds the oil filler cap in place using a slotted screwdriver.

Remove the screw that holds the oil filler cap in place using a slotted screwdriver. - Check the oil level

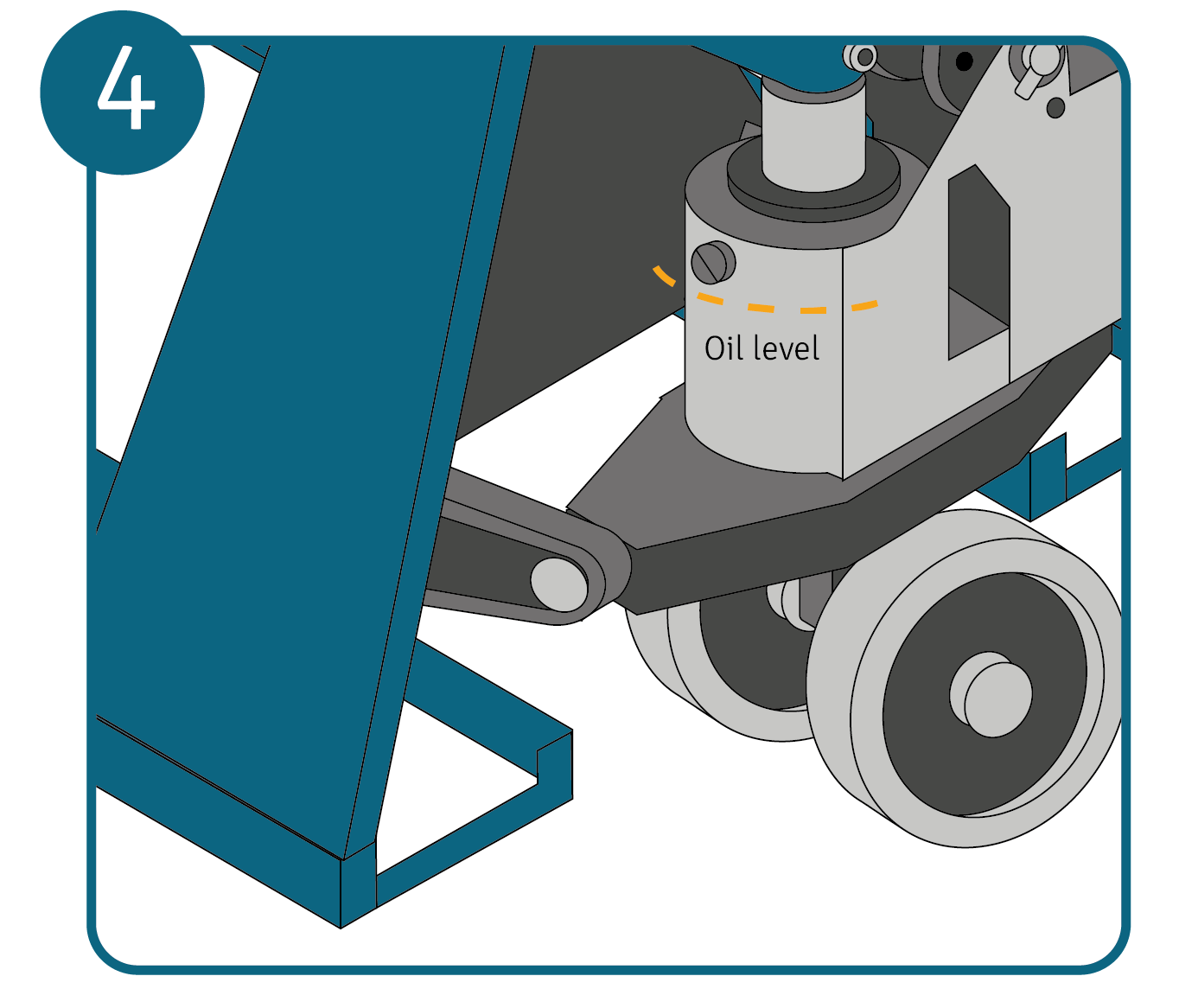

The oil should sit in line with the lower edge of the oil filler cap, or around 1-2cm lower depending on the model. Some pallet trucks have a glass hole through which you can check the oil level without removing the cap.

The oil should sit in line with the lower edge of the oil filler cap, or around 1-2cm lower depending on the model. Some pallet trucks have a glass hole through which you can check the oil level without removing the cap. - Top up the oil

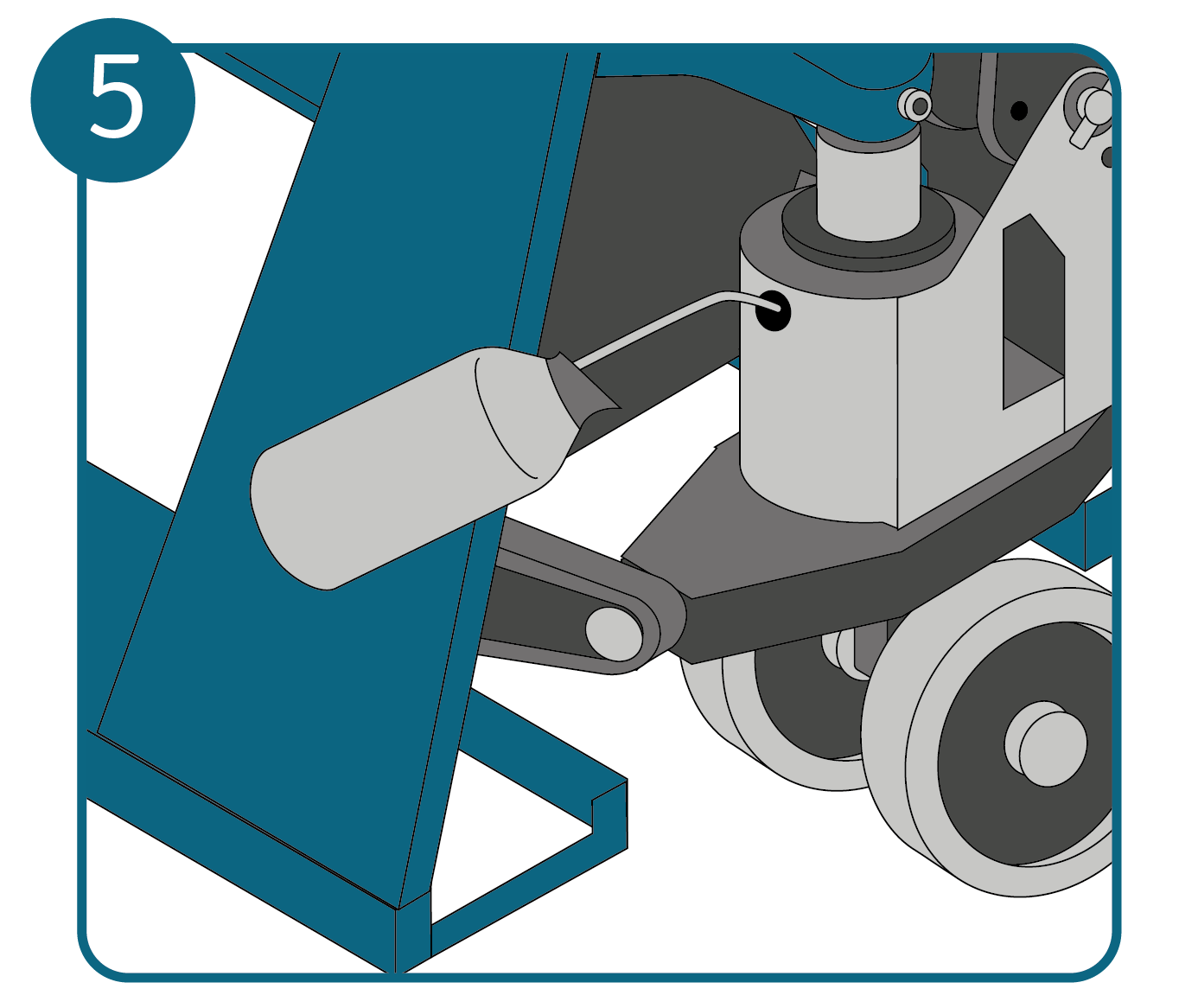

Carefully refill the oil until you reach the desired level. Generally, pallet jacks don’t require too much oil to function – about 0.3 litres is enough. Take care not to spill or overfill.

Carefully refill the oil until you reach the desired level. Generally, pallet jacks don’t require too much oil to function – about 0.3 litres is enough. Take care not to spill or overfill. - Tighten the screw

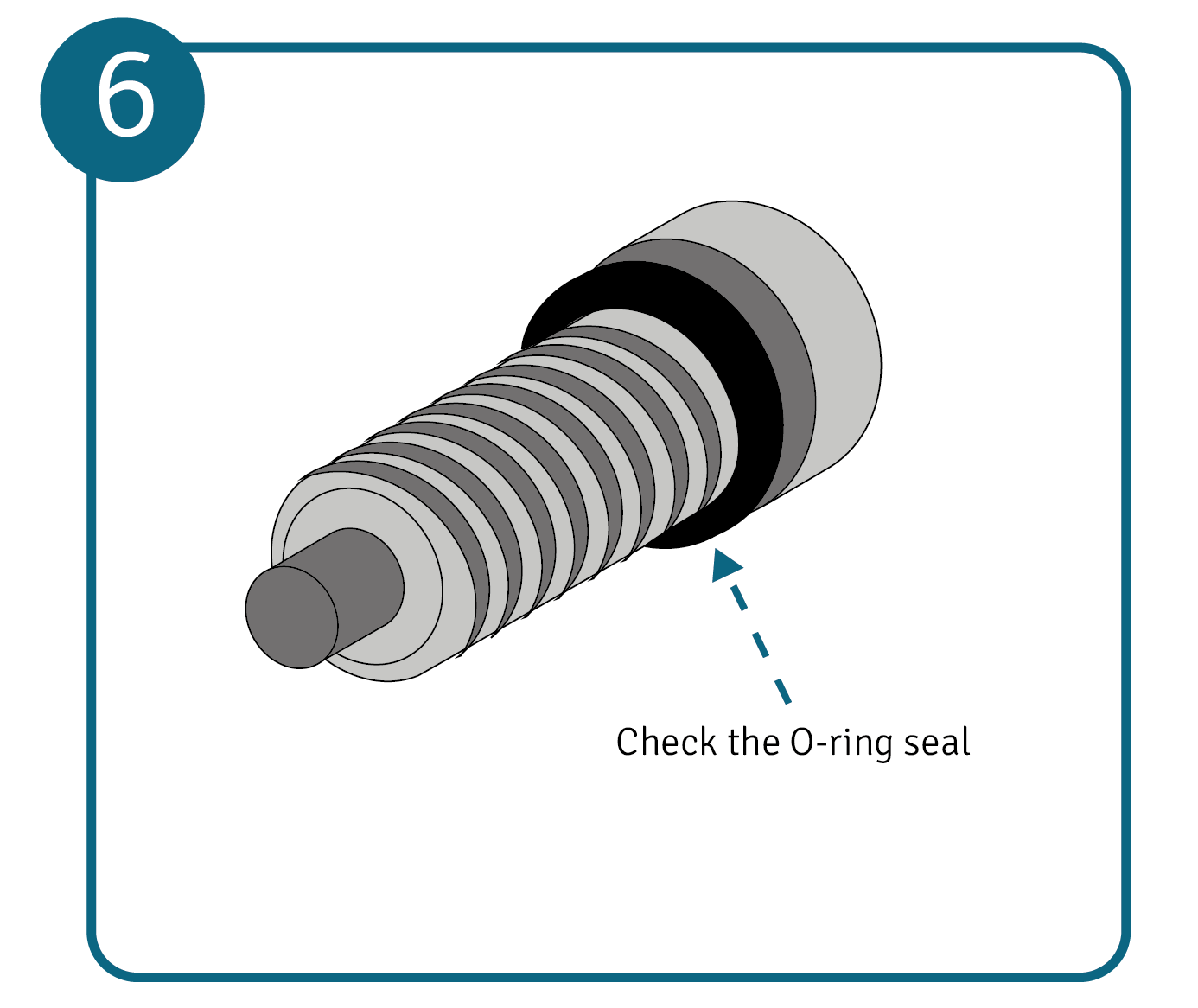

Re-tighten the oil filler cap by securing the screw in place with the slotted screwdriver. Ensure that the O-ring seal fits correctly and isn’t damaged.

Re-tighten the oil filler cap by securing the screw in place with the slotted screwdriver. Ensure that the O-ring seal fits correctly and isn’t damaged. - Test your device

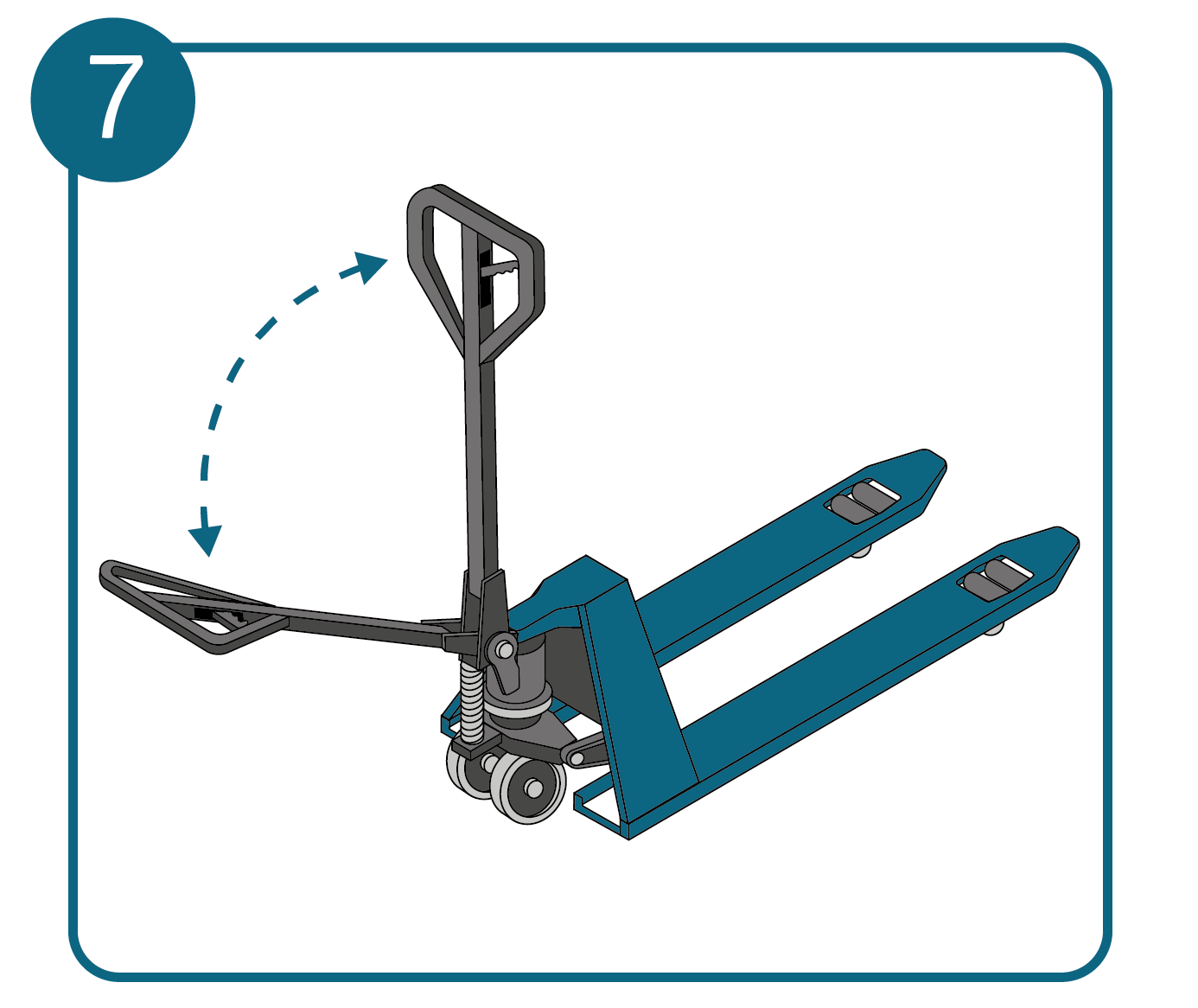

Pump the tow bar 10 to 15 times to vent the hydraulic system and ensure the O-ring is sealed properly. Your pallet jack should be functioning correctly, but if it’s still not possible to lower and raise the forks, you might need to change the oil completely.

Pump the tow bar 10 to 15 times to vent the hydraulic system and ensure the O-ring is sealed properly. Your pallet jack should be functioning correctly, but if it’s still not possible to lower and raise the forks, you might need to change the oil completely.

FAQs about pallet jack oil refill

A pallet jack cannot function without the proper amount of oil. Too much or too little oil can damage a pallet jack, which can lead to malfunctions and breakages. For example, if your forks cannot be lowered properly, it may be an indication that your oil level is too low.

To refill the fluid in your pallet jack, you’ll need the correct oil and a slotted screwdriver. Make sure you always use the same oil that’s already in the hydraulic system – you can find this information in the device’s instruction manual. For pallet jacks in cold climates, a special type of oil may be required.

First off, set the pallet jack down on a hard, flat surface. Lower the pallet jack as far as it will go and move the operating lever to the “lower” position. Then, you are ready to proceed with the next steps for a pallet jack oil refill.

Image source:

© Jungheinrich AG