Table of contents

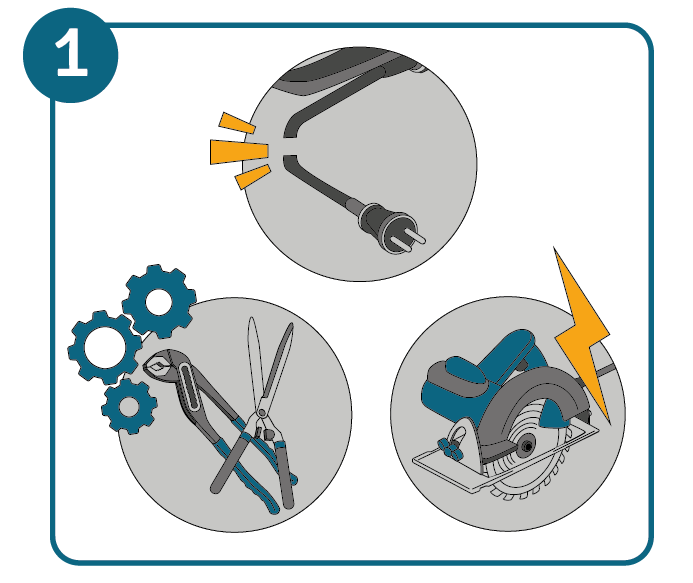

If your cordless screwdriver no longer performs as well as it used to or if five out of ten drill bits are missing from a bit set, you should take action. Tools that are no longer fully functional make work more difficult and can even become a hazard: short circuits or injuries in the workshop are often due to defective tools. In our guide, you can learn how to fix your tools and eliminate damage or defects.

Before you start: identify defective tools

Defective power tools pose a danger because broken cables or defective batteries can cause fires and endanger you and your staff. Therefore, as soon as you notice a defect, remove the tool from the work area. Make sure to mark the tool as defective so that it is not used in your absence.

When you set up your workshop, designate a place or provide a suitable storage container where you can safely keep the tools you have put aside for repair.

Repairing tools: a step-by-step guide

Before you start preparing to fix your tools, you should consider the following points:

- Identify why the tool needs repair

It is not always immediately clear why a tool is not working properly. Therefore, you should do some troubleshooting before repairing the tool. In the case of power tools, check whether there are any visible defects (e.g., damaged cables). Does the tool no longer function at all or only to a limited extent? If the function is limited, find out what exactly is not working: is the problem mechanical or electrical?

It is not always immediately clear why a tool is not working properly. Therefore, you should do some troubleshooting before repairing the tool. In the case of power tools, check whether there are any visible defects (e.g., damaged cables). Does the tool no longer function at all or only to a limited extent? If the function is limited, find out what exactly is not working: is the problem mechanical or electrical?

In the case of mechanical tools, also check whether there are visible defects (e.g., wobbling parts, blunt or crooked cutting surfaces, etc.) and to what extent this affects the function. - For power tools: look at the technical documentation for the tool

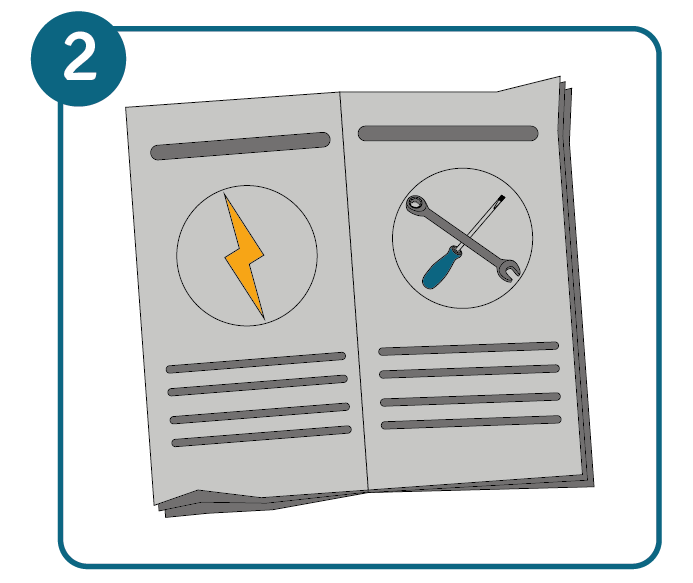

If the tool you want to fix is an electrical appliance, look for your problem in the user manual supplied by the manufacturer. The most common sources of faults, possible damage and their causes are listed there, as well as information on how to solve the problem.

If the tool you want to fix is an electrical appliance, look for your problem in the user manual supplied by the manufacturer. The most common sources of faults, possible damage and their causes are listed there, as well as information on how to solve the problem.

Tip: Don’t have this documentation? You can usually find downloadable instructions on how to fix different tools online. When searching on the manufacturer’s website, enter the name and model number of the tool to access the instructions. - Check the warranty

For both electrical and mechanical tools, check whether the product is still covered by the manufacturer’s warranty. If so, contact the manufacturer to process the repair as a warranty case. In this case, do not attempt to repair the unit yourself, otherwise the warranty may become invalid.

- For power tools: check if you are allowed to repair the tool

Some power tools may only be repaired by qualified personnel. This applies, for example, to equipment such as impact drills or electrical measuring and testing equipment. Decide whether you want to use the manufacturer’s repair service or find an independent provider. If the manufacturer fixes the tool, you can rely on high quality repair and preservation of the warranty. If the product warranty has already expired, you can save costs by using an independent service. If you carry out the repair yourself, you will need suitable electronic tools and spare parts.

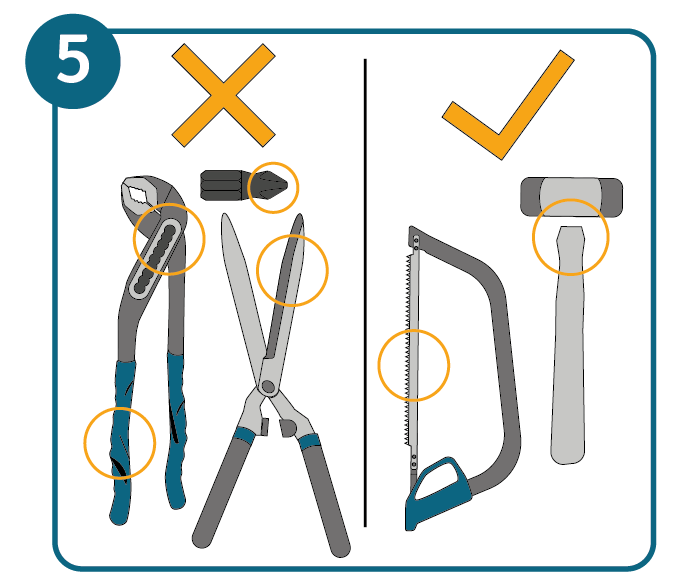

- In case of mechanical tools: check if repair is possible

Repair is not possible for the following functional defects:

Repair is not possible for the following functional defects:

• Wobbly joints on pliers and side cutters

• Blunt or slanted cutting edges on pliers and side cutters

• Loose or damaged tool handles made of plastic or rubber

• Worn or overstretched spanners

• Worn bits for screwdrivers, blunt/worn drills

You can do these repairs yourself:

• Replace a hammer handle

• Clean or sharpen a saw blade - Procure spare parts and accessories

Find out whether the tool manufacturer offers a spare parts service. You cannot go wrong with top quality original spare parts. If this service is not available, seek advice from a specialist dealer or read the product description of the spare part carefully. This will ensure that the spare part is compatible with your tool. Only then should you make the purchase or order.

Find out whether the tool manufacturer offers a spare parts service. You cannot go wrong with top quality original spare parts. If this service is not available, seek advice from a specialist dealer or read the product description of the spare part carefully. This will ensure that the spare part is compatible with your tool. Only then should you make the purchase or order.

Extend the lifespan of your tools

You can do a few things to prolong the lifespan of all the tools in your tool kit, so you don’t have to repair them so often. Here are a few tips:

- If you tidy up your workshop regularly, you will not only have a clear idea of the current state of your tools, but you can store your tools properly to protect them from environmental influences and damage.

- You should clean your tools after every use: this will prevent rust and maintain optimal functionality.

FAQ for repairing tools

Mechanical tools wear out and cannot always be repaired. But when parts of mechanical tools no longer function properly, they should be replaced as soon as possible. There are some parts of mechanical tools that you can repair, for example:

• Replacing hammer handles

• Sharpening and cleaning saw blades

Tools for private use should only be repaired by yourself if you have the necessary expertise. If you use a power tool commercially, you also need the proper qualification to repair it.

If you cannot or do not want to fix a tool yourself, there are various services available that can do this for you:

• Repair service of the tool manufacturer

• Independent repair service (pay attention to the qualification of the repair person-nel if you use your tool commercially!)

Image source:

© gettyimages.de – South_agency