Table of contents

Sawdust, dust and dirt: tools encounter a wide variety of substances during daily use. If you do not know how to clean your tools properly, you may eventually notice the build-up of grime, which can lead to rust and limit tool functionality. In this guide you’ll learn how to correctly maintain your tools, clean dirty and rusty tools and how to store them to increase their long-term service life.

A step-by-step guide to tool cleaning

You should get in the habit of regularly cleaning your tools after each use. You will need a clean and dry cloth, soap, a sponge, sandpaper and a wire brush. You will also need cleaning products specific to the tool. Follow the steps below to learn how to properly remove rust from your tools and equipment and how to keep them clean for best performance.

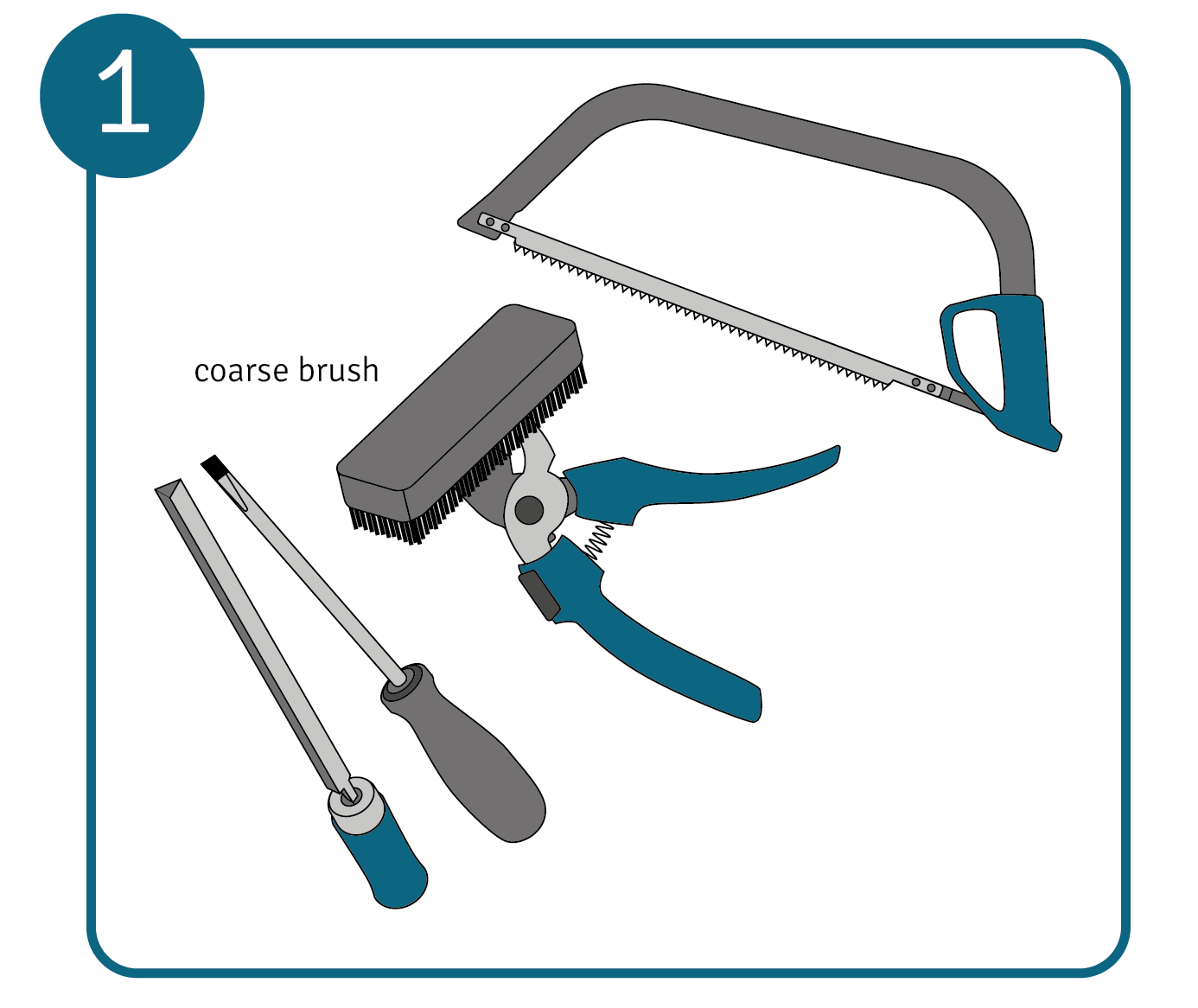

- Remove course dirt

Begin the initial cleaning by brushing the tools thoroughly to remove coarse debris and residue. Using a cloth, wipe each instrument dry. Sensitive tools should not come into contact with rough or coarse brushes. Instead, use a small parts cleaner, ultrasonic cleaner or suitable sandpaper.

Begin the initial cleaning by brushing the tools thoroughly to remove coarse debris and residue. Using a cloth, wipe each instrument dry. Sensitive tools should not come into contact with rough or coarse brushes. Instead, use a small parts cleaner, ultrasonic cleaner or suitable sandpaper.

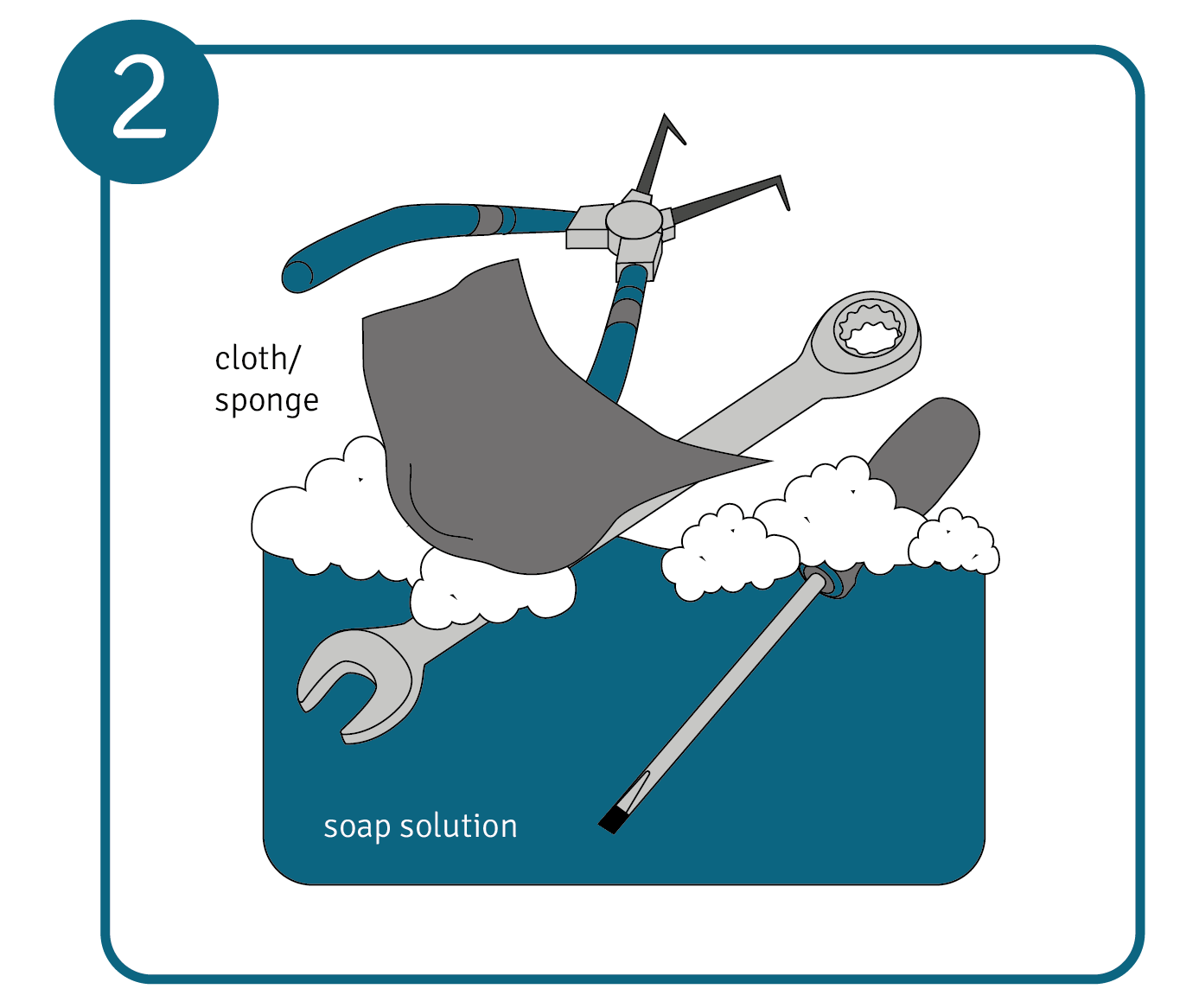

Make sure to run the cloth into all corners and difficult-to-reach areas. Solid deposits of debris and moisture can accumulate here in particular. - Dissolve oil and grease

Tools exposed to grease or oil should be cleaned using an additional step. Greasy and oily tools can easily slip out of your hand causing injury or damage. They can also spread grease to workpieces and work clothing. To remove oily substances and grease, clean the affected tools in a grease-dissolving soap solution with a cloth or sponge, then rub them dry with a clean cloth. Ensure the tool is completely dry before storing it. Failure to do so could result in rust.

Tools exposed to grease or oil should be cleaned using an additional step. Greasy and oily tools can easily slip out of your hand causing injury or damage. They can also spread grease to workpieces and work clothing. To remove oily substances and grease, clean the affected tools in a grease-dissolving soap solution with a cloth or sponge, then rub them dry with a clean cloth. Ensure the tool is completely dry before storing it. Failure to do so could result in rust.

If tools in your workshop require regular removal of oils and grease, it may be worthwhile to stock specialised cleaning products. - Clean rusted tools

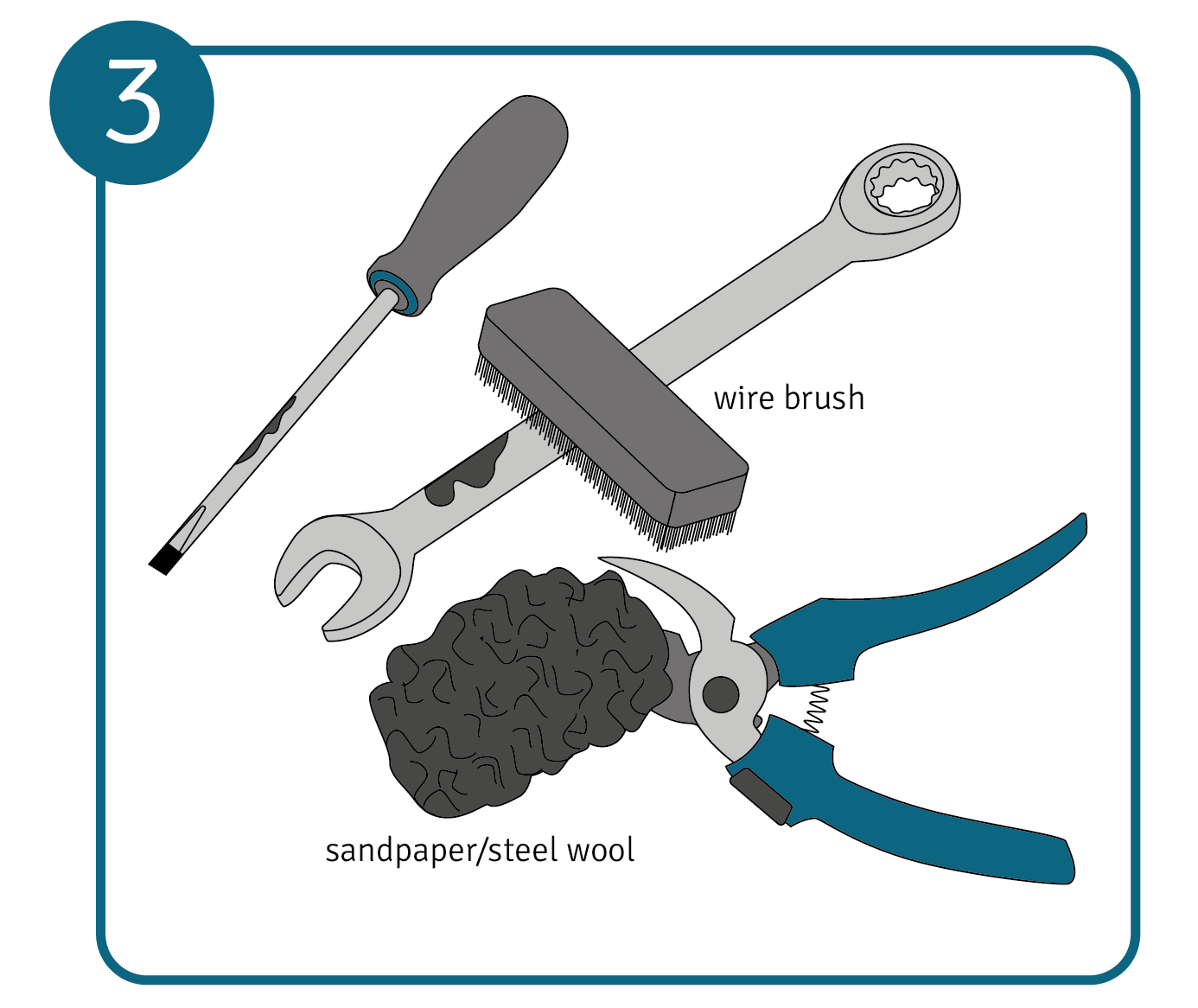

You should immediately treat rusted areas on tools upon discovery. Rust can become porous on tools and can lead to fractures. It can also affect the performance of your equipment. Use a wire brush and then a piece of sandpaper or steel wool to scrub the rust from the tool. Start with the most rusted areas first. By thoroughly removing the rust, you will prevent it from reforming.

You should immediately treat rusted areas on tools upon discovery. Rust can become porous on tools and can lead to fractures. It can also affect the performance of your equipment. Use a wire brush and then a piece of sandpaper or steel wool to scrub the rust from the tool. Start with the most rusted areas first. By thoroughly removing the rust, you will prevent it from reforming. - Polish tools to prevent rust

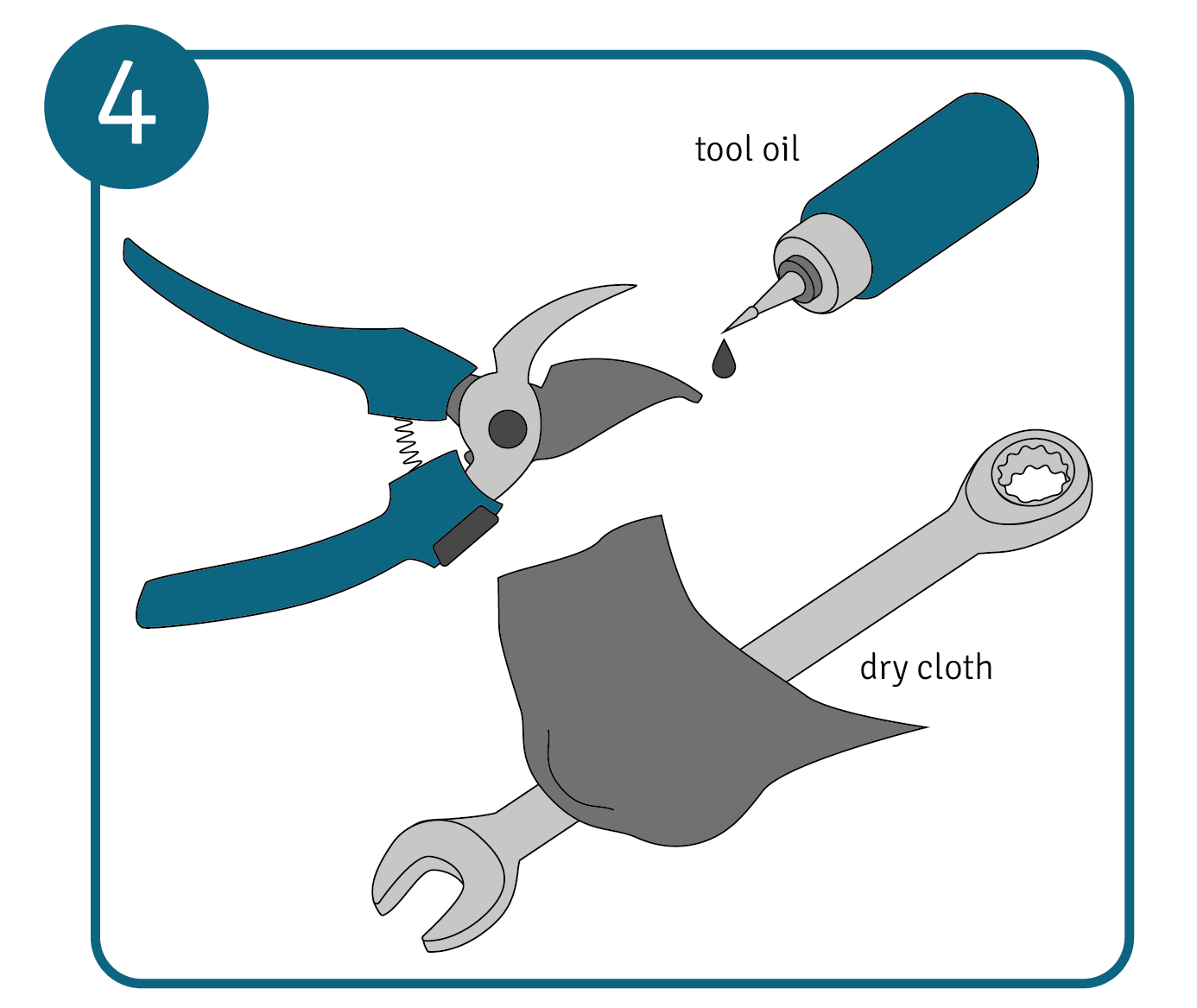

To prevent tools from rusting, polish the tool using tool oil. First ensure the tool is completely dry. Then use a clean, dry cloth to apply the oil. Treat iron and steel tools with tool oil, wax, camellia oil or special anti-rust pastes to protect them. Lubricate machine parts and ensure hydraulic oil (found in machinery like pallet trucks) is always topped up to create a protective layer against rust.

To prevent tools from rusting, polish the tool using tool oil. First ensure the tool is completely dry. Then use a clean, dry cloth to apply the oil. Treat iron and steel tools with tool oil, wax, camellia oil or special anti-rust pastes to protect them. Lubricate machine parts and ensure hydraulic oil (found in machinery like pallet trucks) is always topped up to create a protective layer against rust.

Store tools properly

If tools are not stored properly, they deteriorate faster and become susceptible to rust and other damage. Proper tool maintenance and care entails storing tools neatly and safely. Organise tools by area of use, type and size. Keep your tools protected from air and moisture by storing them in a toolbox, workshop cart, tool cabinet or similar storage unit after use. As a preventative measure, do not keep rust-prone tools exposed to open air. Contact with air and humidity promotes corrosion.

Tool check: regularly inspect tools

Continued use of a damaged tool can spread the damage and lead to poor work results. Therefore, inspecting your tools is an essential part of tool maintenance. Inspect your tools for any defects before and after each use.

Additionally, you should examine and test all your equipment regularly. Do not forget instruments and machines that may be used less frequently. Check tools for integrity, rust and other visible damage before cleaning or using. Pay particular attention to cracks in plastic housings and broken cables. Perform a functional check to identify wear on gaskets and defective power units. It may be necessary to disassemble the tool to inspect individual components.

If you find flaws or damage, set aside the defective tool for tool maintenance and repair. Remember to clearly mark defective tools or store them in a designated place for repair.

FAQ for tool cleaning

Regular tool cleaning prevents rust and reduced functionality. It increases the tool’s service life.

First, remove coarse dirt with a soft cloth or brush. Then use a wire brush to scrub the rust from the tool. Next, switch to a piece of sandpaper or steel wool and continue to scrub the rust from the tool.

Start with the most rusted areas first. Afterwards, it is possible to prevent rust from forming again by treating your tools with tool oil, wax, camellia oil or special anti-rust pastes. Regularly lubricate machine parts and refill hydraulic oil.

In addition to cleaning, be sure to always keep your tools in proper working order. This entails storing the tools properly, inspecting them regularly and repairing them when necessary.

Image source:

© gettyimages.de – ljubaphoto