Table of contents

If drilling through metal is required during craftwork in the hobby workshop or renovation work in your apartment or house, many DIYers are faced with major challenges. For example, what is the best speed for metal drilling? Do I need a coolant? Can I drill through hardened steel? What other important considerations should I pay attention to?

But don’t worry, our professional tips explain the basics of metal drilling, and by the end you will learn:

- How to find suitable drill bits for hard and soft metals

- What is the best speed for metal drilling?

- How to machine metals precisely

- Which metal drilling coolants are necessary?

- How to proceed with precision when drilling metal.

Metal drilling tips – suitable drill bits

Different metals place different demands on a metal drill. So that workpieces or components made of metal can be drilled precisely and safely, a suitable drill bit must be selected. In general, drills made of High-Speed Steel (HSS) are best suited here, as they are available in a variety of designs for different metals but are also manufactured from highly alloyed tool steel that is particularly robust and resistant. As a result, the drills remain dimensionally stable even at temperatures of more than 600° Celsius and enable metal drilling at a cutting speed up to four times higher than drills made of ordinary tool steel.

| HSS-Drill Bit | Application | Material |

|---|---|---|

| Type N | • Ideal for average hard metals • Unsuitable for soft materials | • Steel (500-1,300N/mm²) • Cast iron • Copper • Brass • Zinc • Light metals |

| Type H | • Optimal for hard, tough, brittle, and short-chipping materials | • Steel (from 1,300N/mm²) • Light metals • Bronze • Brass • Plexiglas • Hard plastics • Hard rubber • Rocks and minerals |

| Type W | • For soft, tough and long-chipping materials | • Aluminium • Copper • Soft plastics • Hardwood • Chipboard |

| R | • Rolled drill for average metalwork • Suitable for hand drills and drill stands | • Steel • Cast iron • Bronze • Brass • Aluminium |

| G | • Milled and hardened metal drill for precision work • For pillar drilling machines, lathes and milling | •Steel • Cast steel • Cast iron • Sintered iron • Graphite • Aluminium • Bronze |

| E | • Corresponds to HSS-G drill with additional cobalt alloy • Higher quality and more durable • Particularly heat-resistant | • Stainless steel |

Additional alloys also help to ensure that metal drilling tips do not deform and, depending on the material to be machined and the type of machining required, there are drills with coatings of cobalt (Co), titanium nitride (TiN), titanium carbon nitride (TiCN) or aluminium titanium nitride (AlTiN).

Once you have selected the right drill, you can clamp it in a hand-held machine, a cordless drill, or a drill stand. However, it’s important to remember to always activate the percussion drilling function of the respective machine when drilling holes in metal.

The correct cutting speed and other important basic rules

Rule 1: When drilling metal, enormous forces act in the direction of drilling and rotation. To drill metal workpieces safely, they must therefore always be firmly clamped. For this purpose, vices, clamping ratchets, and screw clamps are suitable for secure fixing on a workbench. You should ensure that workpieces are secured both vertically and horizontally—drill stands, and special machine vices are ideal for this, to safely and precisely maintain a working angle of 90°, which ensures that the hole is not torn out or drilled at an angle into a piece of metal.

Rule 2: If you are drilling holes in metal pipes, they must be securely fixed in a drill rig or vice beforehand. In addition, you can insert a suitable wooden stick into the tube so that it does not bend due to the pressure.

Rule 3: Also avoid applying too much pressure. Unlike with materials made of wood or stone, the drill bit will likely jam in the metal and the tool or workpiece could be damaged.

Rule 4: When drilling metal, it is also essential to maintain the correct cutting speed. The larger diameter of the hole and the harder the metal is, the slower the speed should be set:

| Workpiece | Drill bit-Material | Cutting speed in m/min |

|---|---|---|

| Steel, non-alloy | HSS | 25 |

| HSS alloy | 28 | |

| Mild steel | HSS | 18 |

| HSS alloy | 20 | |

| Stainless steel | HSS | 8 |

| HSS alloy | 10 | |

| High grade steel | HSS | 5 |

| HSS alloy | 10 | |

| Grey cast iron | HSS | 18 |

| HSS alloy | 22 | |

| Aluminium, alloy | HSS | 40 |

| HSS alloy | 50 | |

| Brass | HSS | 40 |

| HSS alloy | 50 |

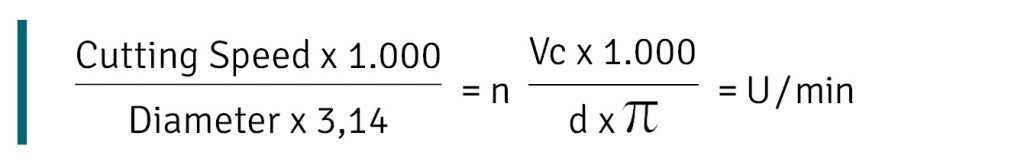

The cutting speed can also be determined using this formula:

Drilling metal – protection from injury

To prevent injuries from sharp-edged chips, it is best to always wear safety goggles and a respirator when drilling metal. It is also advisable to wear headgear, otherwise, your hair could get caught in the drill or metal shavings could hurt your scalp.

Wearing baggy clothing items such as gloves, loose sleeves, or drawstrings in hoods is not safe when metal drilling with rotating machines. The clothing and protective gloves could get caught in the rotating tool parts and cause serious injuries.

Drilling metal – instructions

- Centre punching the hole

Before a hole can be drilled in metal, you should centre punch the exact spot with a suitably sized centre punch and a hammer. In this way, the rotating metal drill will immediately find its footing and will not move out of place.

- Cooling the drill and the workpiece

Lubricants such as cutting or drilling oil are ideal for drilling metals. The workpiece and the drill are wetted with the coolant before starting work and at regular intervals. This reliably dissipates the frictional heat generated and reduces wear on the drill.

- Drilling large holes in metal

To do this, drill a hole with a smaller diameter and expand it to the desired circumference in several drilling passes by selecting a larger drill bit with each pass. The diameter of the smaller drill bit should be at least the same as the core diameter of the next larger drill bit. In this way, the latter cannot slip into the pre-drilled hole.

- Deburring and countersinking

When you have finished drilling, file off any protruding chips at the entry and exit holes. Sharp-edged edges at the edge of the hole can be smoothed with a deburrer. A countersink can then also be used to countersink screws flush into the metal without the screw head protruding from the material.

- Renew the alloy if necessary

After you have drilled a hole in galvanised metal, you should treat the drill site with a suitable zinc or anti-rust spray since the drilling process may have removed the protective alloy, the workpiece may corrode at this point. With the help of the spray, you can renew the protective layer.

FAQ for drilling metal

The most dangerous moment occurs at the end of the drilling process when the drill pierces the hole: At this point, it rotates at a high speed and works against the resistance of the metal. When the workpiece is drilled through completely, the resistance falls away. At this moment, the drill and the machine suddenly sink into the hole. If the workpiece to be machined is not sufficiently secured, it can be torn or even fly around. Therefore, less contact pressure should be applied towards the end of a hole. In addition, a workpiece made of metal should always be fixed particularly firmly.

To ensure that you can cool the drill and the metal sufficiently, you can buy various coolants and lubricants from specialist dealers: For example, special drilling oils are available for this purpose, which can be applied to the drill and the metal with a pipette. Emulsions such as drilling milk or drilling spray, which consist of a mixture of oil and water, can also be used as coolants. But it is not always necessary to additionally cool the drill site since, depending on the material and the speed of rotation, holes can also be drilled dry in metal.

It is possible to use some masonry drills with specially designed carbide tips for drilling holes in mineral metals. Basically, however, this is not advisable because masonry drills are not all-purpose drills and are not suitable for metals, plastics, or wood. Wood drills should also never be used to drill holes in metal: The drills can quickly run hot and break off.

Please note: The regulations mentioned above represent only a selection of the most important legal requirements. Please refer to the listed organisations and directives for more detailed information. If in any doubt, consult experts or contact the relevant regulatory authorities.

Image source:

© gettyimages.de – gilaxia