Table of contents

Pallet trucks are among the most used industrial trucks in small to medium-sized businesses. They are essential for the horizontal transport of goods and their powerful lifting hydraulics allow you to move heavy loads easily. Find out all you need to know on pallet jack functions and their construction in this guide.

Pallet jack construction

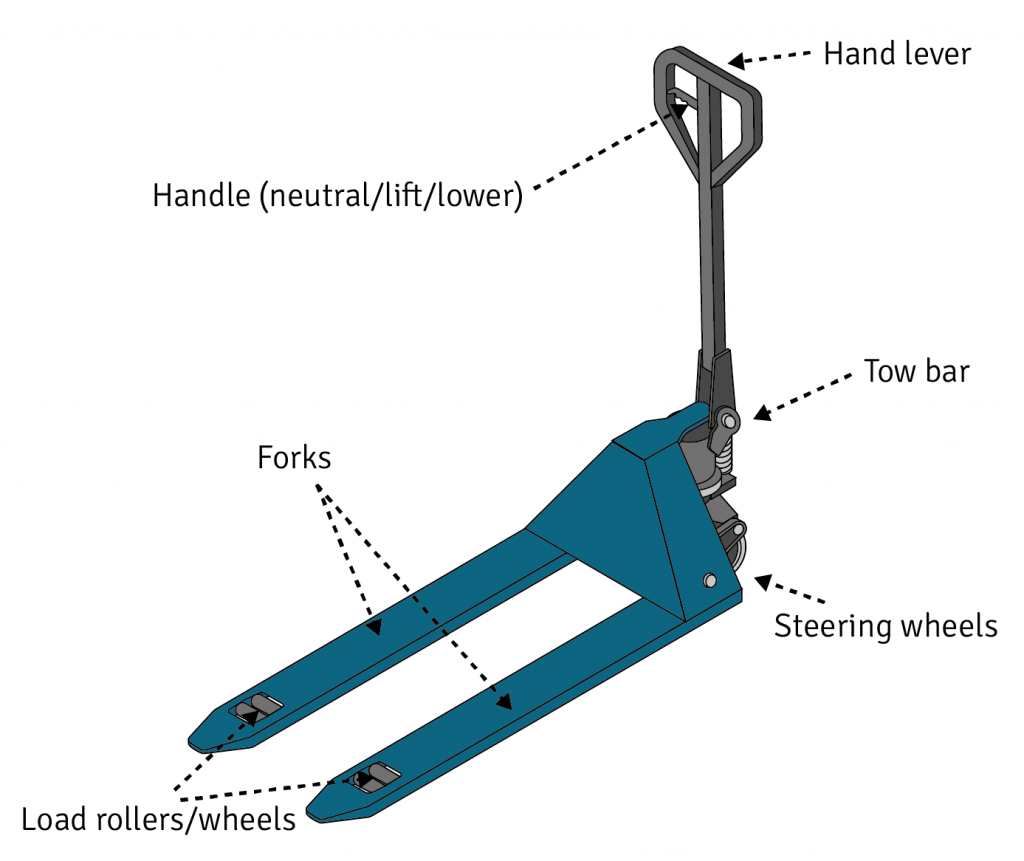

The best way to understand how a pallet truck functions is to first become familiar with their construction. There are different types of pallet jacks, but their operation and design is roughly the same. The following diagram shows the most important parts of a manually operated pallet truck:

Each of these parts has a specific function that contributes to the operation and safety of the pallet truck.

- Handle: You can grasp the handle at the end of the tow bar with both hands and pull or push the pallet truck in the desired direction.

- Hand lever: This lever is set to one of three positions depending on whether you want to lift, lower or move the load.

- Tow bar: The tow bar facilitates the control of the pallet truck and creates hydraulic pressure for the lifting function through a pumping motion.

- Steering wheels: The free-moving castors enable precise control with the smallest possible turning radius.

- Load/fork rollers: Also known as trestle rollers or load wheels, the load rollers at the front end of the forks can only be moved in two directions (forwards and backwards).

- Fork arms: The fork arms are driven into the mounting slots of pallets or pallet cages until the load rests completely on the forks.

Pallet jack functions

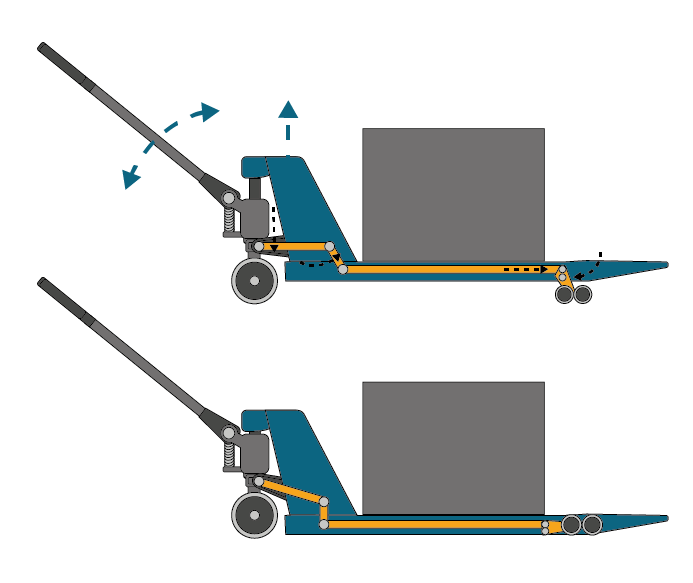

Pallet trucks generally use a hydraulic lifting system regardless of model type. The mechanics of manually operated pallet trucks are explained below.

- Start by pushing the operating lever down to the lift position. This closes the lowering valve so that the hydraulic oil can remain in the lifting cylinder.

- Move the tow bar up and down using the tow bar handle. This forces oil into the lifting cylinder, causing the fork to lift regardless of load.

- The upward movement creates a vacuum, drawing the hydraulic oil from the storage tank into the lifting cylinder. It is fitted with a back pressure valve which prevents the oil from flowing back into the tank.

- At this stage, if the tow bar is depressed, a second check valve will feed hydraulic oil into the lift cylinder causing the pallet truck to lift.

- The more the pumping motion is repeated, the more oil is pumped into the lift cylinder. This raises the fork even further.

- Once the desired height is reached, set the operating lever to the neutral middle position. Now you can transport the load to the desired location.

- Once in position, pull the operating lever up to the lowering position. The lowering valve opens and the hydraulic oil is driven back into the tank by the weight of the load or by the dead weight of the load-handling attachment (fork). This caused the forks to sink slowly downwards.

Electric and manual pallet jacks are differentiated by the energy used to operate the hydraulic pump. Electric pallet jacks use an electric lifting motor rather than manual force.

Do different types of pallet jacks operate differently?

The method of operation is the same despite significant design variations between different types of non-electric and electric pallet jacks. For example, manually operated scissor pallet trucks have unique controls compared to fully automatic electric pallet trucks. Manually operated hand pallet trucks may also be equipped with additional accessories like scales and can be made of stainless steel for use in sensitive operating areas like cleanrooms.

The type of model you use has no influence on the operation of the load-lifting hydraulics, however you must observe correct operation of the pallet truck to ensure safety. Always follow the instructions in the user manual and pay particular attention to the differences between electric and manual pallet trucks:

- Electric pallet trucks assist you with their powerful battery technology. This provides drive support in semi-electric models, while in fully electric models, it provides both drive and lift support.

- As the name suggests, manual pallet trucks require manual operation to function. Even though the lifting action itself is hydraulic, it must be activated by manually pumping the tow bar.

To ensure safety, you should perform and document a thorough check of device functionality, including testing individual components for wear before each use. With proper technical knowledge, you can carry out minor repairs on the pallet truck yourself. It is always best to contact a specialist when in doubt.

FAQ on the operation of pallet trucks

Pallet trucks are available in various designs, but the main components and operation are generally the same for all models:

· Handle

· Hand lever

· Tow bar

· Load rollers/fork rollers/trestle rollers/load wheels

· Load-carrying device/fork arms

The tow bar facilitates the control of the pallet truck and creates the hydraulic pressure for the lifting function through pumping motions.

Each pallet truck model uses the same hydraulic operating principles for lifting loads. The differences in models will determine the proper use of the device to ensure safety. The difference between an electric and a manual pallet truck lies in the type of propulsion.

· Electric pallet trucks assist you with powerful battery technology. In semi-electric models, this provides drive support and in fully electric models, it provides both drive and lift support.

· Manual pallet trucks require you to perform the movement physically. Even though the lifting action itself is hydraulic, it must be activated with manual movements.

Image source:

© Jungheinrich AG