Impact protection

Buying TipsBasic quality

Products reduced to the essentials

For light and occasional use

Good quality

Strong performance

Robust products for everyday use

Premium quality

For the highest load demands

Designed for continuous use

- Suitable for indoor use thanks to powder coating

- Available in 400, 800 or 1,200 mm height.

- Angular shape offers 2-sided protection

7 Working days

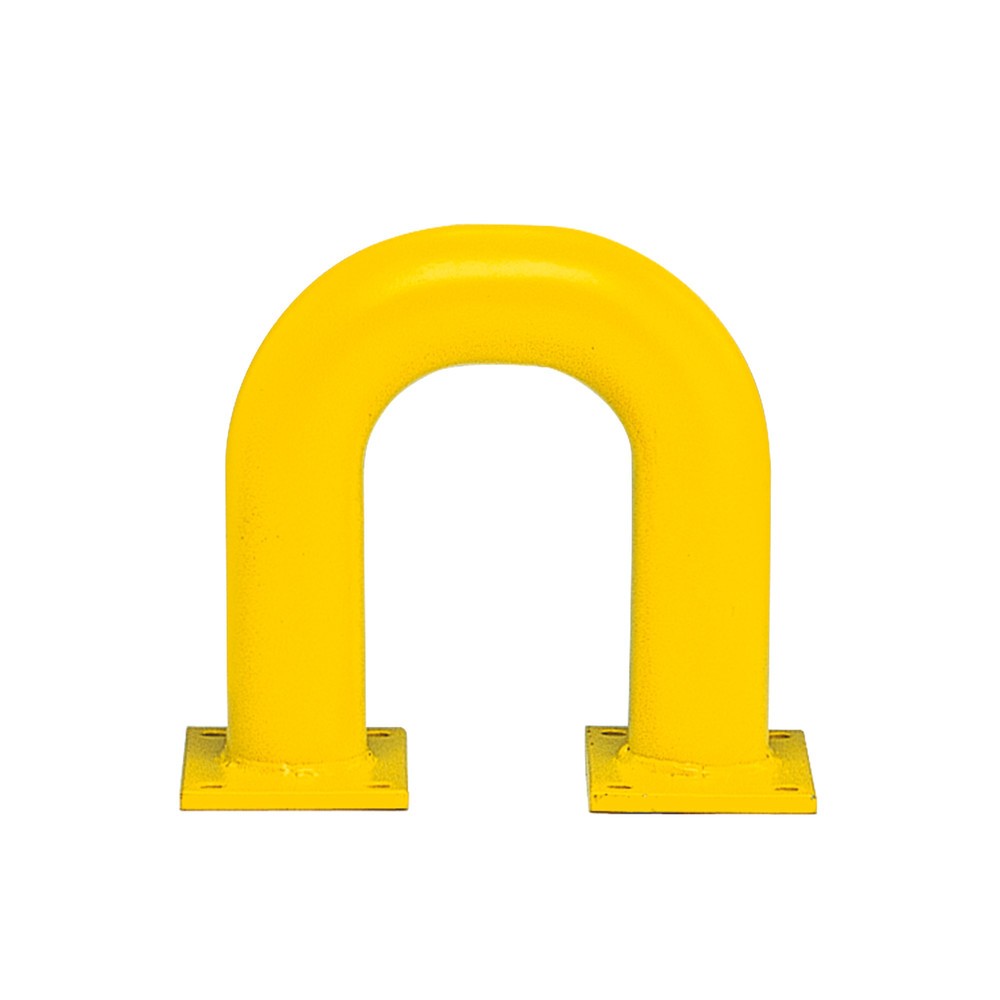

- Powder-coated steel

- For indoor use

- Robust design

8 Working days

- Impact protection made from high-grade steel for indoor use

- 4 mm thick steel plate as underride barrier

- High signal effect thanks to yellow/black plastic coating

7 Working days

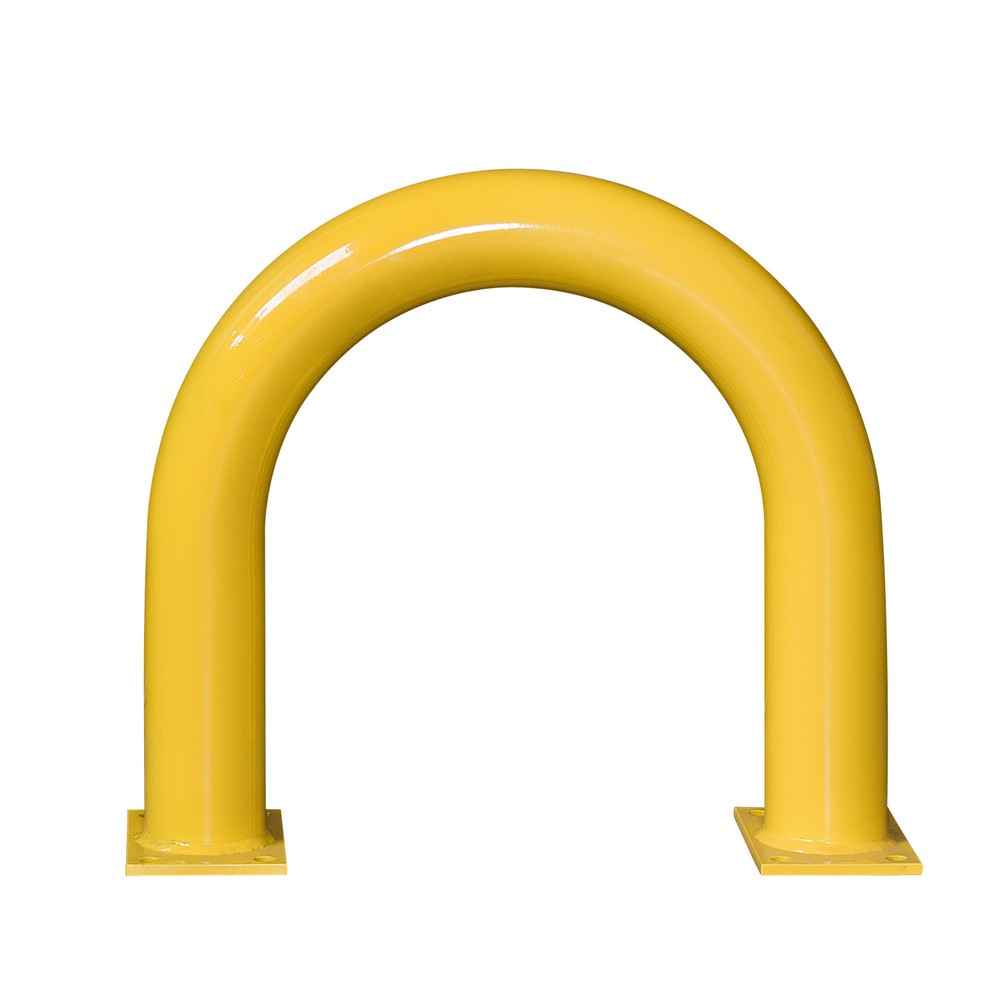

- Hot-dip galvanised hoop guard for outdoor use

- Black/yellow plastic coating

- Attachment via base plates for floor anchoring

7 Working days

- Solid bollard made from hot-dip galvanised steel

- Yellow/black plastic coating for optimum warning effect

- Suitable for indoor and outdoor use

7 Working days

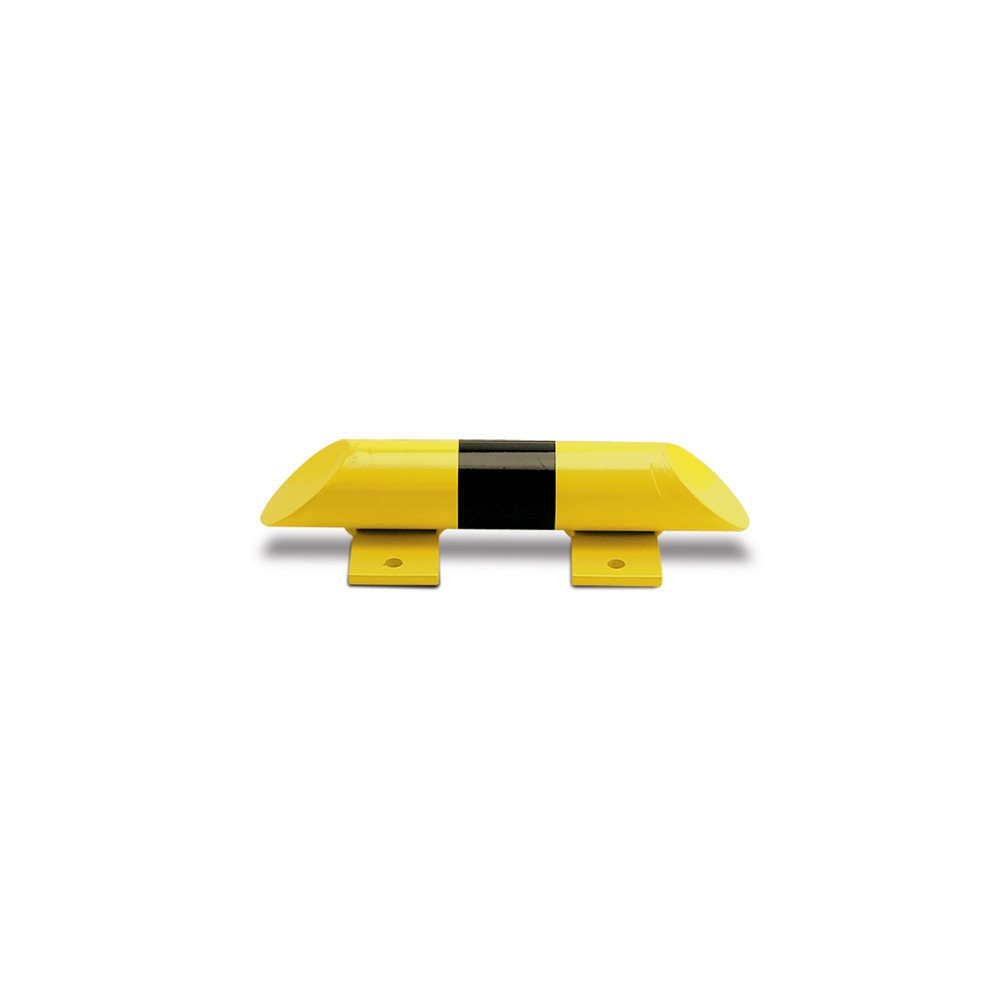

- Durable impact protection bar for indoor use

- Easily visible, yellow plastic coating with contrasting black stripes

- Stable base plates for rapid, secure installation

7 Working days

- Solid bollard made from hot-dip galvanised steel

- Yellow/black plastic coating for optimum warning effect

- Suitable for indoor and outdoor use

7 Working days

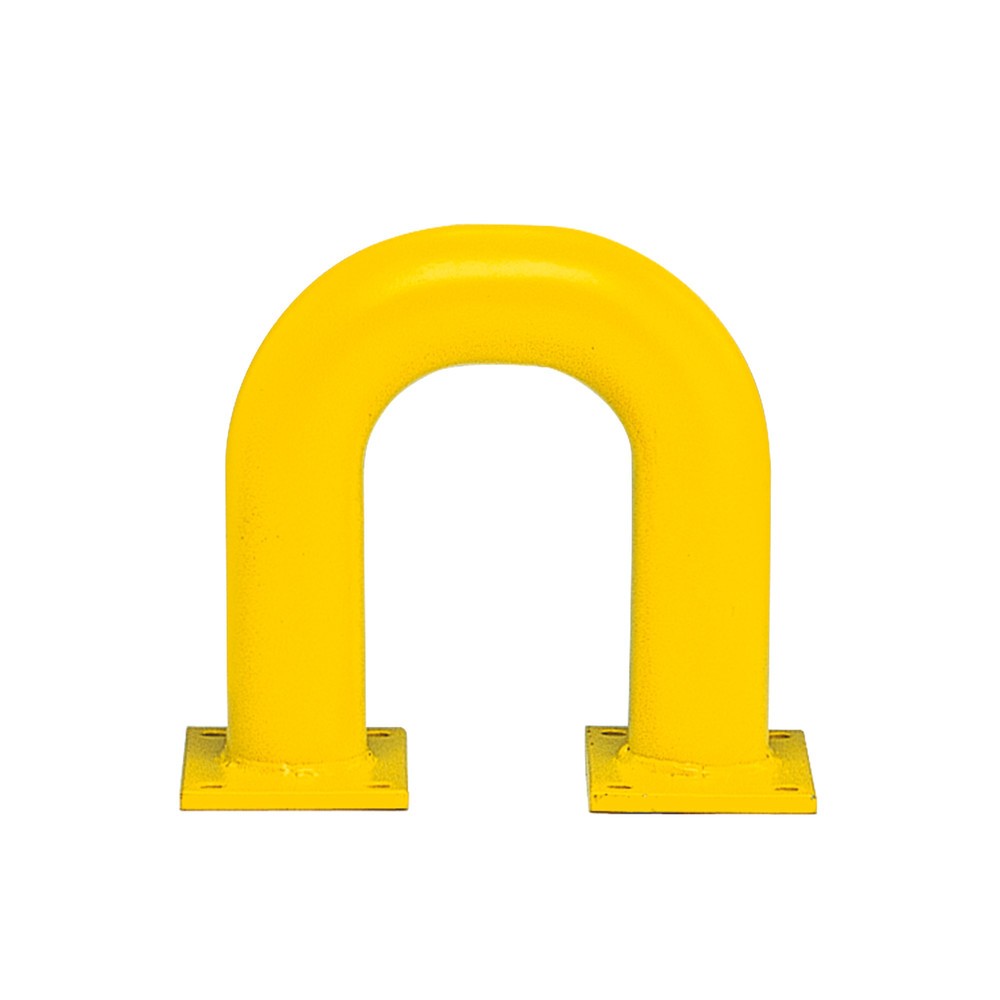

- Solid hoop guard made from 48 mm steel pipe

- Yellow plastic coating with black signal stripes

- Knee rail for reliable impact protection

7 Working days

- Solid hoop guard made from curved steel pipe

- Enhanced safety thanks to additional knee rail

- Galvanised and plastic-coated for outdoor use

7 Working days

- Minimises collision damage caused by transport vehicles

- Made from plastic-coated steel

- For indoor use

7 Working days

- Made from solid steel

- Corrosion-resistant

- Designed for outdoor use

7 Working days

- Collision protection for columns, posts and masts

- Hot-dip galvanised high-grade steel

- Anchored to the floor with 4 base plates

7 Working days

- Collision protection for pillars, posts and columns

- Coated high-grade steel

- Hot-dip galvanised & coated yellow with black stripes

7 Working days

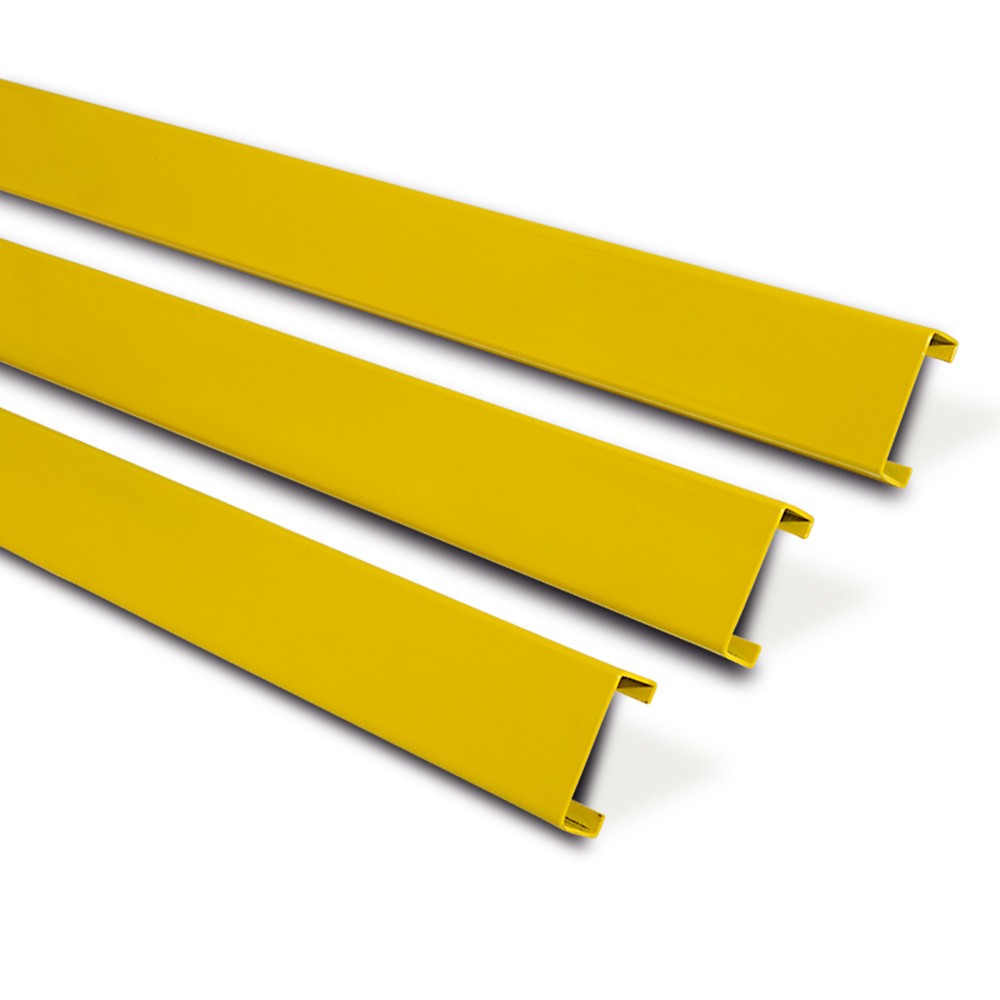

- Complete set with 2 steel barrier boards

- Includes 2 wide corner protectors

- 4 clamps for connecting corners and boards

7 Working days

- For column widths of 200 to 300 mm

- Side parts can be pushed together

- Made from yellow polyethylene

7 Working days

- Made from hot-dip galvanised and coated high-grade-steel

- For outdoor use

- Robust base plate is anchored to the floor

7 Working days

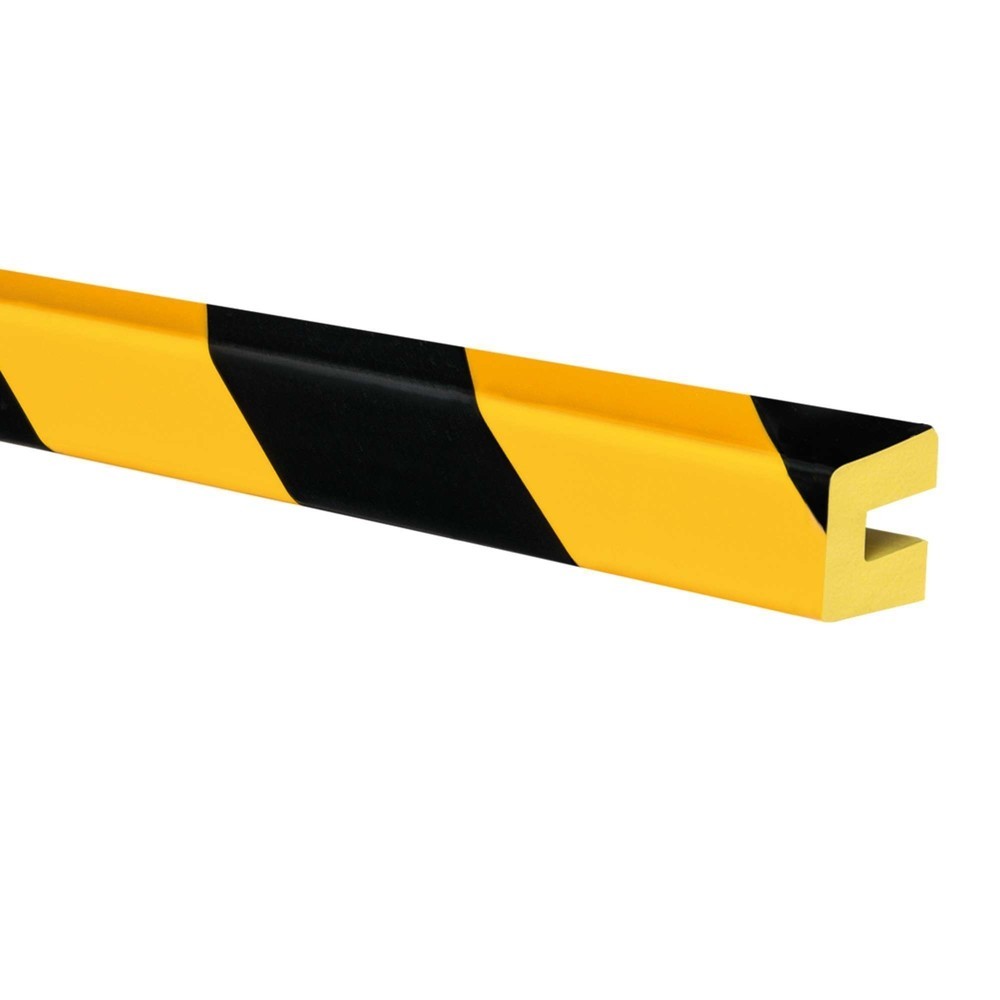

- Slip-on impact protector with rectangular profile

- Made from flexible, non-ageing polyurethane foam

- Resistant to UV light and solvents

7 Working days

- Robust corner hoop guard with underride barrier

- Plastic-coated steel, corrosion-resistant

- Easily visible thanks to yellow signal colour

7 Working days

- Pram protection bracket for dowels made of quality steel.

- Heavy duty attachment with 3 mm wall thickness.

- Yellow plastic coating with black signal strips.

7 Working days

- Solid protection bar made of curved steel tube.

- Side wall mounting via insert sleeve (not included).

- Removable for

7 Working days

- Highly robust hoop guard for indoor use, diameter 76 mm

- Quality high-grade steel with a thickness of 3 mm

- Yellow plastic coating with black signal stripes for enhanced visibility

7 Working days

- The corner hoop guard offers reliable impact protection

- Signal colours ensure excellent visibility

- The hoop guard is hot-dip galvanised and thus protected against corrosion

7 Working days

- Solid bollard made from hot-dip galvanised steel

- Yellow/black plastic coating for optimum warning effect

- Suitable for indoor and outdoor use

7 Working days

- The hoop guard for indoor use has a diameter of 108 mm

- The solid steel construction features a material thickness of 3.6 mm

- 2 base plates are integrated for straightforward assembly

7 Working days

Impact protectors for improved workplace safety

Impact protectors guarantee the necessary safety of your employees and prevent damage to operational equipment. Our guide will help you find the best impact guards for your needs.

- Impact protectors from our online shop

- Why are impact protectors important in the workplace?

- How to find the right impact protectors

- Impact protection hoops, railings, barriers and bollards

- Impact protection designed to be mounted onto objects: column impact guards and corner protectors

- Certified impact protection for racking

- FAQ on impact protection

1. Impact protectors from our online shop

2. Why are impact protectors important in the workplace?

Properly installed impact guards are essential for operational safety and may be a legal requirement depending on your workplace environment. All warehouse impact protection products in our shop meet relevant industry standards and are certified for their intended applications. Correctly chosen and installed impact protectors contribute to workplace safety in several ways:

- Accident prevention: The right impact protector will allow you to separate work areas from one another and help prevent collisions. Impact protectors can also mark safe traffic routes for employees or customers, thereby preventing accidents between pedestrians and industrial trucks from occurring in the first place.

- Collision and collapse protection: Impact guards are designed to absorb the impact of collisions, such as when an industrial truck collides with a storage rack. They minimise the risk of damage to factory equipment and prevent shelves from toppling over. Pipework, columns and walls will also remain undamaged in a collision, depending on the protective capacity of the impact protectors.

- Cost savings: Collisions resulting in damage to vehicles and storage facilities can lead to expensive repairs and downtime. Although investing in high-quality impact protectors may initially incur costs, the expenditure quickly pays for itself as accidents and resulting costs are avoided. This is particularly worthwhile for operations using high-value machinery.

- Compliance with safety guidelines: While not a strict legal requirement, fitting impact guards to fixed racking is strongly recommended as best practice under UK health and safety guidance – particularly in warehouses where non-guided materials handling equipment such as stacker trucks and pallet trucks operate. By installing compliant impact protection, you demonstrate a proactive approach to your duty of care under the Health and Safety at Work Act 1974.

3. How to find the right impact protectors

Legal guidance can help determine which impact guards are best suited to your working environment. However, there are other parameters that can help you select the right impact protector for your specific requirements:

- Which operational areas or equipment need protection? We stock certified impact guards for racking, column impact guards, edge protection, and more. The intended use determines the type of impact protection required.

- Against which hazards should the impact protectors provide protection? This concerns the stability that collision protection must offer, which may may depend on the material and how you install your impact guards.

- Do you want to buy impact guards for indoor or outdoor areas? At Jungheinrich PROFISHOP, you will find impact protectors for both indoor and outdoor use. For outdoor applications, the material should be weather-resistant and corrosion-resistant.

Selecting impact protectors by function

Before purchasing impact protection, it is essential to determine what exactly you will be using it for. Do you need to protect storage equipment, and if so, which items? Should the impact protectors serve as a barriers or markers? Do you need cushioning impact guards?

| Function | Suitable warehouse impact protection |

|---|---|

Separation of different operating areas

|

|

Marking and securing of traffic routes

|

|

Impact protectors against collisions with industrial trucks and other vehicles

|

|

Securing hazardous zones

|

|

Securing of shelves

|

|

Securing columns, posts or pipes

|

|

Fall protection

|

|

Material

We offer impact protectors made of steel, with or without coatings, as well as various plastics and polyurethane foam. All construction materials are suitable for indoor use. Whilst most plastic versions also meet the highest requirements for impact protectors in outdoor areas, for steel elements used outdoors you should ensure hot-dip galvanisation or additional corrosion protection.

| Material/Area | Indoor area | Outdoor area |

|---|---|---|

| Polyethylene (PE) | ✔ | ✔ |

| PU foam | ✔ | ✔ |

| MEMAPLEX® and MONOPLEX® | ✔ | ✔ |

| Metal with plastic coating | ✔ | × |

| Powder-coated steel | ✔ | × |

| Hot-dip galvanised steel | ✔ | ✔ |

4. Impact protection hoops, railings, barriers and bollards

Jungheinrich PROFISHOP stocks warehouse impact protection that must be installed either at a distance from the hazard areas or directly in front of the objects that need to be protected. Impact protectors installed at a distance primarily serve as barriers against potential collisions. Additionally, impact guards can also serve as an efficient traffic control system. We provide a variety of products for this purpose.

Impact protection barriers

Impact protection barriers are highly versatile. We offer a wide range of impact protection barriers:

- Round arch or inverted U-shape

- With crossbars

- As a two-part round arch construction

- As a floor barrier

- With an angled profile

- With underrun protection

The brackets are constructed of strong tubular steel and can be bolted to the floor with the use of base plates. For operational areas that require a high level of impact protection, such as those where vehicles are travelling at high speeds, warehouse impact protection barriers can be fixed to the ground with cement. Our impact protection barriers are available in different diameters and wall thicknesses, allowing for optimal adaptation to your company's specific requirements.

Characteristics of impact protection barriers:

| Parameter | Details |

|---|---|

| Protective effect |

|

| Material |

|

| Area of application |

|

Impact protection railings

Warehouse impact protection railings are used to separate or mark paths in different operating areas. Unlike impact protection barriers, railings offer a continuous barrier but can be equipped with door elements specifically designed for impact protection railings.

Warehouse railings can be securely fixed into the ground using base plates to provide better resistance to approaching vehicles and potential collisions. Depending on the operating area, cushioning elements may also be used: railing posts with an inclined angle give way and divert the force of collision as gently as possible.

Characteristics of impact protection railings:

| Parameter | Details |

|---|---|

| Protective impact |

|

| Material |

|

| Area of application |

|

Impact protection boards

If you need to protect larger operating areas from potential damage caused by larger industrial machinery, but still need access to walls, stored goods, or work equipment, impact protection boards are an ideal choice.

These boards, which are only around 30-40cm high, provide effective warehouse impact protection against stacker trucks or pallet jacks by absorbing the impact of vehicles at an ideal height. These types of collision prevention elements are usually anchored directly into the ground. This is achieved with the use of robust support posts, which provide optimal force absorption.

Impact protection boards also offer maximum safety when positioned in areas frequented by heavy or fast-moving vehicles. Extension sets can be used to adjust the boards to the conditions on site, allowing them to even be set up around corners.

Please note that impact protection boards do not provide underride protection. Suitable impact protection barriers with underride protection should be used for this purpose.

Characteristics of impact protection boards:

| Parameter | Details |

|---|---|

| Protective impact |

|

| Material |

|

| Area of application |

|

Impact protection bollard

Impact protection bollards are primarily used to secure traffic routes. They offer reliable protection for people, buildings and machines, especially when stacker trucks, pallet trucks and other vehicles are present on company premises. Impact protectors, such as these bollards, can even call attention to inconspicuous curves or building corners that may otherwise be easily missed.

Depending on the intended use, bollards can be anchored or secured with concrete into the ground. Thanks to their simple installation, warehouse impact protection bollards can also be used on a temporary basis – for example, when traffic routes change regularly, or a construction site needs to be secured. HDPE bollards with tilting and auto-recovery features provide a gentler cushioning effect during collisions, thereby reducing the damage caused to vehicles.

Characteristics of impact protection bollards:

| Parameter | Details |

|---|---|

| Protective impact |

|

| Material |

|

| Area of application |

|

5. Impact protection designed to be mounted onto objects: column impact guards and corner protectors

Some of our impact protectors mount directly onto structural elements. They serve two purposes: their conspicuous markings warn of potential hazards such as sharp edges or protrusions, while the cushioned material absorbs impact energy in the event of a collision

Column protection

Depending on the type, our column protection products offer adequate to good collision protection. They are equipped with cavities inside that are supported by plastic slats. This design not only makes the collision protection particularly stable, but also resistant to stress cracks: the slats ensure that the collision protection is flexible and can spring back on impact. This absorbs the impact energy and minimises or even prevents damage to vehicles.

Column collision protection is available from Jungheinrich PROFISHOP in fixed sizes or in flexible designs that can be individually fitted around bollards or columns.

Characteristics of column protectors:

| Parameter | Details |

|---|---|

| Protective impact |

|

| Material |

|

| Area of application |

|

Corner protectors

Our corner protection products provide reliable cushioning for corners and edges, such as those found on railings, passages, or pipes. Made from durable and solvent-resistant polyurethane foam (PU foam), our corner and edge protectors can be attached using self-adhesive or magnetic coatings.

To ensure an optimal fit on the edges that need to be padded, our shop offers corner protection in various types:

- Semi-circular

- Circular

- Rectangular

- Trapezoidal

- Angular

Characteristics of corner protectors:

| Parameter | Details |

|---|---|

| Protective impact |

|

| Material |

|

| Area of application |

|

6. Certified impact protection for racking

While not a legal requirement, fitting impact guards to fixed racking is strongly recommended as best practice, particularly for heavy-duty industrial shelving in high-traffic areas. At Jungheinrich PROFISHOP, you can buy impact guards designed to meet UK safety standards. These warehouse impact protection elements are primarily intended to prevent racking from being damaged or collapsing due to collisions with forklift trucks and other materials handling equipment.

- All our impact protection elements for racking achieve a minimum height of 30 cm

- The elements feature yellow or black/yellow colouring

- The products withstand impact forces from 400 Nm in accordance with the minimum recommended standard

Rack protection can be attached to different parts of your racking system depending on the version – whether that's the rack legs, front faces, or rack ends. Impact protection corners are particularly important for safeguarding fixed racking, as they anchor securely into the ground using concrete screws and come in a range of types to suit your setup.

Characteristics of rack protectors:

| Parameter | Details |

|---|---|

| Protective impact |

|

| Profiles |

|

| Material |

|

| Area of application |

|

7. FAQ on impact protection

The terms impact protectors and collision are often used synonymously, and both refer to the protection of objects and people in the warehouse area from collision damage caused by industrial trucks. Certified products are offered under both terms which, depending on the version, absorb the impact energy of industrial trucks in the warehouse or are suitable for demarcating and designating traffic routes so that collisions are prevented from the outset.

Proper installation is a crucial prerequisite for impact protection to serve its purpose. For many impact protection products, the accessories necessary for attachment are already included. For models that are fixed to walls or the floor, it is essential that the ground is stable enough to anchor the product securely; otherwise, it may tip over upon impact. Impact protection bollards can be anchored into concrete for increased stability. You can also find instructions for professional assembly in the assembly and operating manual that comes with each impact protection product.

Impact protection products are sometimes equipped with an underrun protection. A protective wall that nearly touches the floor is placed between the sides of the bracket. This wall prevents stacker trucks from getting stuck in the impact protector as the machine’s fork cannot accidentally slide underneath it.

The best material for warehouse impact protection products depends on three main factors:

- The most critical factor is the level of performance that the collision protection needs to provide. Generally, the thicker the material and diameter, the more resistant the impact protection.

- Steel or plastic have different advantages and disadvantages when it comes to using impact protection in outdoor areas. Only plastic or hot-dip galvanised steel collision protection products can offer reliable protection against rust damage caused by moisture. Steel can cause damage to the protective zinc layer after collisions with vehicles, however it is preferable to plastic products for permanent UV resistance. Plastic impact protection is less durable when exposed to constant sunlight.

- Although steel elements are typically better at absorbing forceful impact, plastic impact protection products provide better protection for the approaching vehicle.