Table of contents

In many industries, handling explosive substances is part of everyday operations. To ensure that you can prevent explosions from the outset or control them as effectively as possible in an emergency, there is a zone categorisation for explosion protection for affected areas. These so-called ATEX zones or ex zones (explosion zones) provide information on suitable protective measures for people and the environment. This guide explains how the zones are categorised and labelled.

Definition: ATEX zone classification defines areas where there is a risk of explosion. The hazard ex-ists primarily where explosive substances are processed, manufactured, transported or stored.

Which areas are at risk of explosion?

Explosive substances are widespread in some industries, such as in the extraction and processing of crude oil and natural gas, in mining, or in the chemical industry. In principle, they can also occur in areas such as in warehouses or intralogistics. In any case, you should take special precautions to minimise the risk of explosions as much as possible:

- To ensure the safety of employees and visitors

- To protect the natural surroundings and the worksite in general

Together with fire protection, explosion protection is a central component of the operational safety concept.Firstly, you should carry out a risk assessment to identify potentially explosive areas at the worksite.

In principle, hazardous area classification includes all storage, production and extraction sites where explosive gas or explosive dust occurs, can occur, or is deliberately used.

Practical examples:

- Hazardous materials storage

- Gas-operated systems

- Use of chemicals

What obligations do companies with ATEX zones have?

If there is a risk of explosion in your company and ex zones have been defined for this purpose, you should implement the following measures:

• Labelling ATEX zones

• Do not use ignition sources in corresponding areas

• Take preventive measures to avoid explosions

• Document the explosion protection

The risk of explosion is not the same everywhere and for all substances. For this reason, potentially explosive areas are categorised into zones, commonly known as ATEX zones or ex zones. This categorisation allows you to optimally adapt the safety measures to the respective area following the risk assessment. On this basis, measures are defined for safety during daily work, but also for emergencies.

Ex zone classification according to ATEX

The ATEX Directive 1999/92/EC stipulates that every company must draw up an explosion protection document aspart of the prescribed risk assessment, in which potentially explosive atmospheres are categorised into zones.

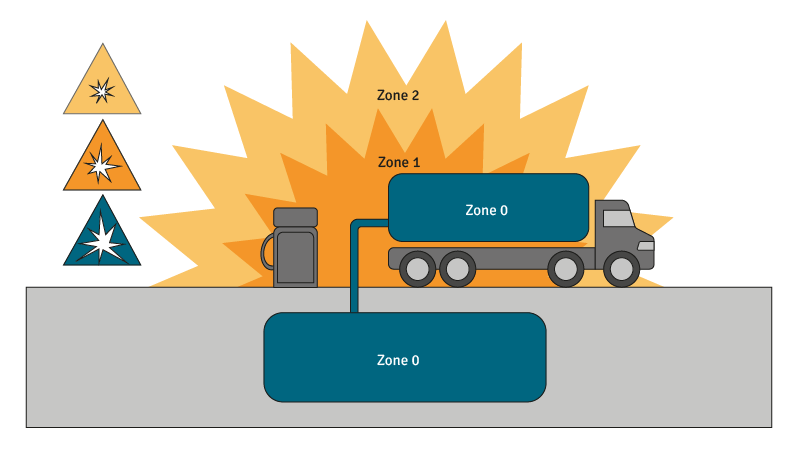

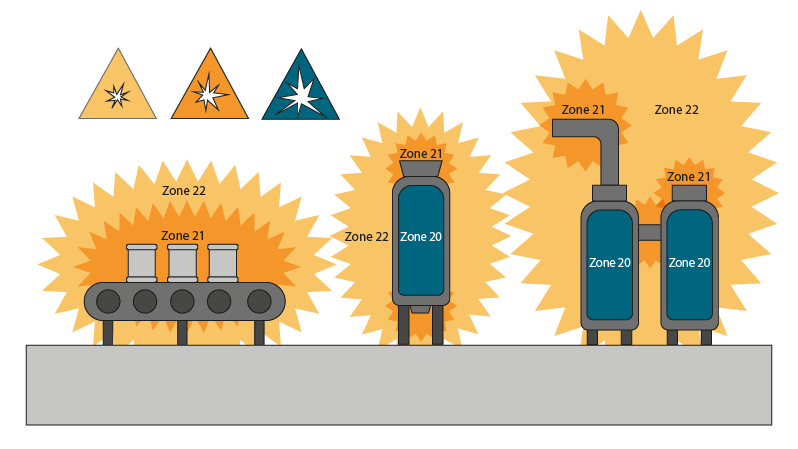

The criteria and designation of the explosion protection zones can be found in documentation of the Dangerous Substances and Explosive Atmospheres Regulations 2002 (DSEAR). In addition to the frequency and duration of the explosion hazard in the respective area, a distinction is also made as to whether the hazardous explosive atmosphere is caused by flammable gases, vapours and mists, or by combustible dusts. This results in the six different ATEX zones.

| ATEX zone | Cause | Duration and frequency | Example |

|---|---|---|---|

| Zone 0 | Mixture of air and flammable gas, vapour or mist | Constantly, over long periods of time or frequently | Container with liquid solvents |

| Zone 1 | Same as Zone 0 | May occasionally form during normal operation | Extraction with dust extractor |

| Zone 2 | Same as Zone 0 | Does not usually occur in normal operation, and if it does, then only rarely and for a short time | Clean gas area after extraction |

| ATEX zone | Duration and frequency | Example |

|---|---|---|

| Zone 20 | Constantly, over long periods of time or frequently | Powder mixers, filters, dryers, mills |

| Zone 21 | May occasionally form during normal operation | Areas outside or inside dust-enclosing containers, e.g. silos |

| Zone 22 | Does not usually occur in normal operation, and if it does, then only rarely and for a short time | Bags with dusty contents, pneumatic conveyors |

It is worth noting that the terms “frequently”, “occasionally” and “rarely” are not clearly defined. Concrete figures are not specified in any of the standards, but experts agree that:

• “Frequently” means more than 50 per cent of the operating time.

• “Occasionally” means it may occur at irregular intervals, for example during bleeding or sampling, one to 10 per cent of the operating time.

When in doubt, you should assign the higher ATEX zone.

Laws and guidelines for hazardous area classification

In the UK, the most important information for working with hazardous substances, which also include flammable and explosive substances, can be found in the DSEARregulations and the ATEX operating guidelines of the European Union (EU). It is clear from these legal texts that the processes of every operational risk assessment also apply to explosion protection.

It’s important to note, that despite its departure from the EU, the UK will continue to apply APEX zone regulations in accordance with those of the European Union.

According to the DSEAR requirements, employers and the self-employed are responsible for assessing risk in the workplace or at the worksite as it relates to dangerous substances as much as possible. You must therefore go through the following steps if there is a risk of explosion:

- Replace explosive substances with non-hazardous substancesor switch operation to processes or equipment without explosion hazard

- Avoid the occurrence of an explosion as much as possible by technical means and/or organisational measures such as fire protection

- Protect people and surrounding areas to minimise the impact of an explosion, such as through structural measures (fire doors), personal protective equipment, escape and rescue plan, suitable extinguishing agents, employee training, etc.

This order of priority must be strictly adhered to. This means that you only need to think about the categorisation of ATEX zones if you cannot avoid potentially explosive substances, devices or processes in your company. In this case, the UK government provides guidance for businesses across industries.

The labelling of potentially explosive atmospheres

The ATEX guidelines state that potentially explosive areas must be clearly labelled. For this purpose, yellow safety signs with the black lettering “EX” must be clearly visible.

In addition to signage, you must mark the areas in the escape and rescue plan and regularly train your employees on occupational safety, how to use fire extinguishers and what to do in emergencies.

Correctly labelling devices for use in potentially explosive atmospheres

Not only the ATEX zones, but also the devices and machinery used in these areas must be correctly la-belled. The basis for this are the Supply of Machinery (Safety) Regulations 2008 and the international standard IEC 60079. The safety sign for devices and machinery in ATEX zones is the following:

The identification number must also be visible on the rating plate.

FAQ on ATEX zones

Before defining safety measures, potentially explosive areas must first be identified as part of an operational risk assessment. Hazardous areas are basically all storage, production and conveying sites where explosive gas or explosive dust occurs, can occur, or is deliberately used. In practice, this can be, for example, a hazardous materials warehouse, a gas-operated plant, or the generation of hazardous vapours when using chemicals.

As the risk of explosion is not the same everywhere and for all substances, potentially explosive atmospheres are categorised into zones, the ATEX zones. In addition to the frequency and duration of the explosion hazard in the respective area, a distinction is also made as to whether the hazardous explosive atmosphere is caused by flammable gases, vapours and mists, or by combustible dusts.

The ATEX directive defines six different ATEX zones.

Zone 0: A place in which an explosive atmosphere consisting of a mixture with air of flammable substances in the form of gas, vapour or mist is present continuously or for long periods or frequently.

Zone 1: A place in which an explosive atmosphere consisting of a mixture with air of flammable substances in the form of gas, vapour or mist is likely to occur in normal operation.

Zone 2: A place in which an explosive atmosphere consisting of a mixture with air of flammable substances in the form of gas, vapour or mist is not likely to occur in normal operation but, if it does occur, will persist for a short period only.

Zone 20: A place in which an explosive atmosphere in the form of a cloud of combustible dust is present continuously, for long periods or frequently.

Zone 21: A place in which an explosive atmosphere in the form of a cloud of combustible dust is likely to occur in normal operation occasionally.

Zone 22: A place in which an explosive atmosphere in the form of a cloud of combustible dust is not likely to occur in normal operation but, if it does occur, will persist for a short period only.

Please note: The regulations mentioned here are only a selection of the most important le-gal requirements. For detailed information, please refer to the collections of regulations and legal texts listed and, where applicable, other reliable sources on the topic. When in doubt, consult experts on the specific implementation in your company.

Image source:

© gettyimages.de – DSCimage