Table of contents

Electric industrial trucks – such as forklifts, stackers, and pallet trucks – require a drive battery for operation. These days, these may be either lithium-ion, lead-gel, nickel-cadmium or iron-phosphate batteries, depending on the vehicle. In all these battery types, electrical energy is converted into chemical energy via a chemical process in the cells. The energy stored in this way is then converted back into electrical energy for driving the vehicle and for raising and lowering the mast or lifting platform.

Although the term “batteries” is usually used in battery technology for forklifts and other industrial trucks, it is not 100% accurate for these kinds of vehicles. The energy storage units used in electric pallet trucks, electric stacker trucks, and electric forklift trucks are rechargeable accumulators, also known as secondary cells. The term “batteries” is used when recharging is not possible. These non-rechargeable primary cells consist, for example, of zinc-carbon or alkaline-manganese. Nevertheless, we will use the term ‘battery’ below to introduce you to battery technology for forklift trucks and industrial trucks.

Structure and operation of battery technology for forklifts

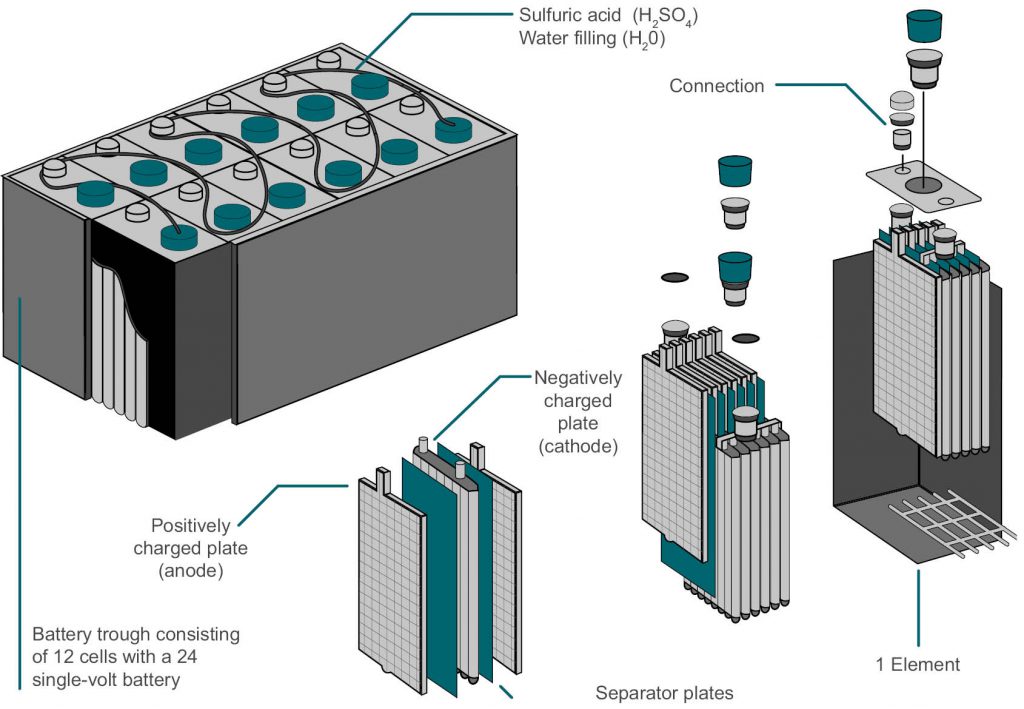

Batteries for electric stacker trucks, electric pallet trucks and electric forklifts are galvanic elements in which conductive objects are electrically separated. As such, each battery consists of individual cells connected in parallel.

Each battery cell consists of:

- the cathode (positive pole) made of metal oxide

- the anode (negative pole) made of metallic material

- an electrolyte

- a separator plate (separator)

When the battery is discharged – for example, when the mast of an electric forklift is raised – positively charged ions inside the battery flow from the anode to the cathode. They pass through the separator, which is permeable to ions but not electrically conductive. This component thus prevents a short circuit in the battery cells. During the discharging process, the acid density in the batteries drops and the cell voltage falls.

Direct current is required to recharge the battery. The battery charger draws three-phase or alternating current from the mains. It transforms the mains voltage to the required battery voltage and rectifies the current. In the process, electrical energy is converted into chemical energy. The ions flow back from the cathode to the anode, the original charge gradient is restored, and the acid density increases.

For the batteries to reach the nominal voltage required for forklift and industrial truck operation, several battery cells are connected in series to form a traction battery.

Traction batteries for forklifts, stackers and pallet trucks

The battery technology for forklift trucks and industrial trucks described above is known as a traction battery. This differs from conventional starter batteries, used mainly in cars or for IC engine-powered forklifts. Starter batteries are primarily designed to deliver a high amount of electricity quickly to start a car or diesel forklift’s internal combustion engine.

Traction batteries, on the other hand, are specifically designed for forklifts and industrial trucks. They are also known as armour plate batteries, with each cell constructed of layers of plates. The positive plate is armoured with glass fabric. This design increases the mechanical stability of the cells and the cycle stability, which is the number of possible recharges.

The principle here is the series-connected rows of individual battery cells. Since each cell has a nominal voltage of 2 volts, voltages add up when cells are connected. For example, this results in an operating voltage of 48 V for an electric lift truck with 24 x 2-volt cells. The cell types result from the number of plates in a cell and the forklift battery capacity is specified in Ah.

This video compares lithium-ion batteries to lead-acid batteries and illustrates the advantages of both battery types:

Lead-acid battery technology for forklifts, stackers and pallet trucks

In a lead-acid battery, the anode consists of lead and the cathode of lead oxide. The electrolyte used is sulfuric acid diluted with distilled water. These types of batteries are powerful and significantly cheaper than lithium-ion batteries.

Due to comparatively long charging times and a low energy density, they are ideal in the 1-shift system and for occasional use in industrial trucks. However, if electric forklifts or pallet trucks are used in high-performance warehouses, it is better to use the more powerful nickel-cadmium or lithium-ion batteries with a better forklift battery life.

Lead-acid batteries have other downsides. When charging, water in the battery cells evaporates and must be topped up regularly. You should check the electrolyte level no sooner than half an hour after charging is complete. If there is no longer enough of the solution in the cells, they must be refilled with distilled, demineralized water. In addition, the water level must be checked at least once a week.

Another critical issue that may arise when charging lead-acid batteries is gassing. This occurs at the end of the charging process and initiates electrolyte circulation, mixing the electrolytes in the battery cells and preventing acid stratification. At the same time, the temperature in the battery cells rises, which has a negative effect on service life. This temperature rise can also lead to the production of oxyhydrogen gas – an explosive mixture of hydrogen and oxygen. In modern lead-acid batteries, gassing can be dispensed of by injecting air into the batteries. This also reduces charging time. Lead batteries with electrolyte circulation via air injection are also suitable for intermediate charging.

Maintenance-free battery technology – lead-gel batteries

Lead-gel and fleece batteries are maintenance-free. This means battery water refills are not required over the entire service life. The cells are sealed gas-tight, so there are no bad smells from hydrogen gas.

In lead-gel or non-woven batteries, the electrolyte in the cells is no longer liquid due to added silica. In a fleece battery, a glass fibre fleece between the electrodes completely absorbs the electrolyte solution, allowing the batteries to be charged without a gassing phase. However, a maintenance-free battery may only be discharged to 60% of its rated capacity (compared with 80% for wet batteries).

Nickel-cadmium batteries

Nickel-cadmium batteries (Ni-Cd batteries) are more powerful and easier to handle than lead-acid batteries. With potassium hydroxide used as a catalyst, the overall cell stability is higher than that of lead-acid batteries. This is thanks to minimal self-discharge and the higher charging and discharging currents that are generated. Nickel-cadium batteries are also suitable for intermediate charging, making them ideal for use in industrial trucks in a multi-shift operation. Unlike lithium-ion, Ni-Cd batteries are also significantly less sensitive to temperature and operate better in extreme temperature ranges from -40° to +50°C.

The memory effect, which causes the battery’s capacity to diminish in the long term, is only found in earlier generations of nickel-cadmium batteries. Modern variants are only affected to a small extent, making complete discharging before each charging cycle no longer necessary.

Lithium-ion batteries

Lithium-ion batteries belong to a new generation of battery technology for forklifts, stackers and pallet trucks. These powerful batteries have a high energy density, enabling them to carry high currents, and are comparatively compact. In lithium-ion batteries, ionized lithium atoms move in anhydrous electrolyte or polymer between a positive electrode made of metal oxide and a negative electrode made of graphite. Nonwovens or polymer films serve as separators.

Lithium-ion battery technology has a barely measurable memory effect and a long service life – when properly cared for. In addition, unlike lead-acid batteries, lithium-ion batteries can be charged at any time. The shorter charging times make them ideal for use in environments with multi-shift operations and high handling rates. They also require less frequent recharging thanks to their higher efficiency, with energy being recovered through braking. However, due to the temperature sensitivity, this is currently only fully beneficial for indoor electric stacker trucks.

Nevertheless, the advantages of lithium-ion batteries clearly outweigh the disadvantages. Although they are significantly more expensive than lead-acid or Ni-Cd batteries and their contact with water or excessive ambient temperature can cause fires, lithium-ion batteries are among the most powerful and versatile batteries currently available.

Selecting the right battery technology for forklifts and other industrial trucks

The right forklift battery technology for you depends largely on how you plan to use your handling equipment. For use in high-performance situations, battery technologies such as lithium-ion or nickel-cadmium are the best choice. If trucks only play a minor role in your business, lead-acid or lead-gel batteries are an inexpensive and completely adequate traction battery option.

It is true that care, maintenance, storage and disposal for all battery types requires a certain level of expertise and legally required operating equipment, such as hazardous material storage or other devices. In addition, trained employees are required to handle battery technology in order to avoid damage to health and property.

Image source:

© gettyimages.de – vgajic