Electric pallet stackers for convenient load transport

With an electric pallet stacker, you can move pallets quickly and safely from A to B and transport them to great heights. Discover the different types of electric stacker truck and what you need to look out for when choosing one in our buying guide.

- What is an electric stacker truck?

- Our electric pallet stacker portfolio

- How to find the right powered pallet stacker

- Intended working environment for the electric pallet stacker

- Drive Type: Semi-electric or fully electric

- Choose an electric pallet stacker with sufficient lifting height

- The load capacity of your electric pallet stacker

- Fork lengths and fork equipment

- Transport goods and load carriers

- Battery size and type

- Wheel configuration

- Pedestrian operation

- Practical functions of electric pallet stackers

- Individual equipment options

- FAQ for electric pallet stacker

1. What is an electric stacker truck?

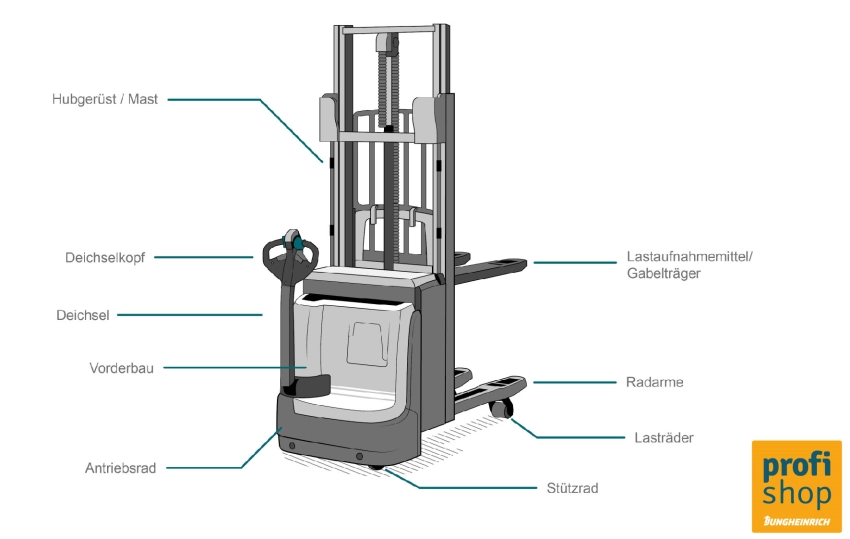

The electric stacker’s integrated mast design – unlike pallet trucks which have no mast - enables both ground-level goods transport and vertical handling of Euro mesh boxes, pallets and other goods when stacking and retrieving them in warehouse racking systems. The electric lifting mechanism allows ergonomic and safe load handling without the need for intense muscle power.

Electric pallet stackers are also known as electric stackers, electric stacker trucks, power stackers, powered pallet stackers, pedestrian stackers or E-stackers.

How do electric pallet stackers and electric forklifts differ and which truck should be used when?

Unlike counterbalance forklifts, electric pallet stackers require no counterweight as their load centre of gravity is within the fork construction. This makes them very manoeuvrable and enables operation in warehouse aisles with narrow working widths.

However, counterbalance forklifts are better suited to demanding operational environments or outdoors. They can be used in damp or condensation-affected work areas like cold stores or outdoor warehouses. E-stackers, by contrast, require specialised (deep-freeze) equipment for this.

Additionally, electric stackers are unsuitable for very dusty environments or on oily surfaces. In these harsher conditions, robust combustion engine forklifts are the better choice for reliable performance.

2. Our electric pallet stacker portfolio

In our online shop, you’ll find the right electric stacker for every application and requirement:

3. How to find the right powered pallet stacker

Before you buy a new powered pallet stacker, developing a detailed requirements profile is essential. This will help you understand your specific operational needs and guide you to the optimum industrial truck for you, determined by the characteristics of your specific work environment. The following questions will help you define the selection criteria:

- How many hours will my power stacker be used per day?

- What driving distances do I typically need to cover?

- At what heights should my goods be stored?

- What are the ceiling heights of my premises?

- Will my electric pallet truck require transportation by lorry?

- Will my power stacker be used to load/unload trucks?

- Will I transport fragile goods?

- Are my routes free of barriers such as inclines or ramps?

All the relevant parameters for the forklift selection are explained in detail below to help you answer these questions.

4. Intended working environment for the electric pallet stacker

The intended working environment is an important criterion for selecting the right electric pallet stacker. This includes, for example, whether the truck is to be used indoors or outdoors, whether you need it for stacking and unstacking goods under extreme temperature conditions, such as in deep-freeze warehouses, and whether the electric stacker must be suitable for loading and unloading trucks.

| Application criteria | Suitable electric power stacker |

|---|---|

| Indoor and/or outdoor use |

|

| Use with trucks |

|

| Ceiling height or lowest clearance height |

|

| Length of transport routes |

|

| Gradients |

|

We provide specialised electric pallet stacker solutions for more challenging operational environments. Jungheinrich stainless steel electric pallet stackers are perfect for use in clean rooms, hygiene-sensitive areas, and corrosive environments. If you need to stack and unstack goods in very cold or humid environments, e.g. in (deep-freeze) cold stores or greenhouses, we also offer electric stackers with optional cold store equipment.

5. Drive Type: Semi-electric or fully electric

We offer electric pallet stackers with two different drive types:

- Fully electric stackers with two motors are a comprehensive solution for storage and transport tasks. The drive motor controls the forward and reverse movement to transport loads to the desired storage location. Upon arrival, the independent lift motor raises or lowers the fork carriage and its load. All functions are controlled by the operator controls located on the tiller head.

- Semi-electric stackers, on the other hand, have only one motor. The lifting function is electrically powered, while the travel movement is performed manually via the tiller. Ergonomically positioned guide handles facilitate comfortable pushing and manoeuvring during stacking and retrieval.

Understanding your operational requirements is essential before choosing an electric forklift. Semi-electric stackers offer a cost-effective solution for businesses with occasional or infrequent stacking tasks. However, for applications involving greater lifting heights or regular daily use, fully electric models provide superior performance and operational efficiency.

6. Choose an electric pallet stacker with sufficient lifting height

The lifting mast, also known as the lift mast, moves the load carrier and the load itself vertically. The mast’s dimensions are essential when it comes to comparing different electric stackers. You need a truck that suits how high your storage racks are or at which height your loads must be stored and retrieved. The following technical terms and specs will help you make your informed decision:

| Term | Meaning |

|---|---|

| Lift mast, overall height |

The overall height is the maximum height of an industrial truck, measured from the ground. However, in the case of industrial trucks with high-lift equipment, it can change. This depends on the mast and on whether it is retracted or extended. |

| Maximum lifting height |

This term refers to the greatest possible distance from the ground to the highest position of the load handling attachment (top edge of the fork or platform) in the lifted state. |

| Free lift |

This refers to the lifting height up to which the load handling attachment can move without changing the overall height of the mast. The free lift function is ideal when stacking is required at low ceiling heights, e.g. in containers, enclosed rail freight cars or basements |

Mast types

We provide electric pallet stacker trucks with four different mast types:

- Simplex mast = single lift mast

- Monomast = single column single mast

- Duplex mast = two-section telescopic mast – available with and without additional lift (free lift)

- Triplex mast = three-part telescopic mast with additional lift (free stroke)

All electric pallet stacker models operate on the same fundamental principle: a lift motor drives the vertical movement of the lift carriage, fork carriage and the load within the mast structure. On some models, you can extend the mast telescopically two or even three times. This allows much higher storage spaces to be reached without restricting mobility in low working areas. Our video explains this principle using the electric high-lift power stacker with duplex mast as an example:

| Mast type | Construction | Advantages | Disadavantages |

|---|---|---|---|

Simplex

|

|

|

|

Mono

|

|

|

|

Duplex

|

|

|

|

Triplex

|

|

|

|

Always pay attention to the ground type to ensure sufficient stability: Uneven or damaged floors can affect the stacker’s balance when stacking and unstacking palletised goods.

7. The load capacity of your electric pallet stacker

The load capacity (or rated load capacity) is the maximum weight limit for loading an electric pallet stacker. Exceeding this limit may compromise the load-bearing elements and jeopardise safe handling operations. Every electric stacker includes a load capacity diagram that shows how the load capacity varies based on lifting height and load centre of gravity.

For more detailed information about load capacity, see our guide on load capacity for stackers and pallet trucks.

8. Fork lengths and fork equipment

Electric pallet stackers have a standard fork length of 1150 mm. This makes picking up Euro pallets and mesh containers easy and avoids multiple manoeuvres. Fork width generally varies between 540 and 570 mm, depending on the model. The general rule is: the heavier the electric power stacker the greater its load-bearing capacity (considering the fork dimension and quality of the steel used).

Additionally, our electric pallet stackers in wide dimensions are suitable for picking up special pallets. On request, we also offer custom variants, e.g. for electric stacker trucks with special fork lengths.

For specific applications, fork equipment such as magnetic anti-slip pads provides additional benefits, protecting sensitive surfaces, reducing vibrations and transport noise, minimising goods damage, and preventing load slippage during operation.

9. Transport goods and load carriers

Electric stacker trucks are designed for transporting loaded Euro pallets. However, depending on the fork dimensions and load capacity, you can also use them to move loading aids such as storage boxes, ISO containers and wire mesh boxes or even long goods and pallets in special sizes.

For picking up, transporting, and stacking and unstacking particularly sensitive goods such as glassware or sensitive electronic components, buy our electric pallet stackers with proportional hydraulics. This advanced feature provides precise operational control, enabling careful lifting, lowering, and positioning of fragile loads on shelves or floor surfaces without risk of damage.

10. Battery size and type

Our power stackers are equipped with one of the following three rechargeable battery types as standard:

- Lead-gel rechargeable batteries or lead-acid batteries: These powerful traction batteries provide reliable capacity for warehouse work. An integrated display instrument on the chassis always keeps you informed of your battery charge level and operating hours. When the battery requires recharging, the electric stacker’s integrated charger enables convenient charging at any 230-volt socket.

- Lithium-ion battery: When you need more performance power, we recommend our energy-efficient lithium-ion stacker trucks. The batteries offer a long service life, high energy efficiency, a compact design, and easy charging between uses. The integrated charger provides rapid recharging regardless of location.

A direct performance comparison of the three battery types will help you select the suitable option for your specific requirements:

| Features | Lithium-Ion Battery | Lead-Acid Battery | Lead-Gel Battery |

|---|---|---|---|

| Life expectancy | ~ 3000 charge cycles |

~ 1200 charge cycles |

~ 800 charge cycles |

| Charging time | 1.5–3 hours |

Minimum 6.5 hours |

Minimum 6.5 hours |

| Maintenance | None |

Refill of demineralized water 1x per week |

None |

| Intermediate charging | Possible at any time |

Limited possibility |

Not possible |

| Battery change during multi-shift operation | Avoidable with intermediate charging |

Required |

Not recommended |

| Advantages |

|

|

|

| Disadvantages |

|

|

|

| Application |

- Quickly ready for use due to short charging times |

|

|

This video compares lithium-ion batteries with lead-acid batteries and shows you the advantages of both battery types:

11. Wheel configuration

Every Jungheinrich and Ameise® electric pallet stacker has a 4-point chassis consisting of a drive wheel, a support wheel and two or four fork rollers to achieve optimum stability and driving safety when stacking and retrieving loads.

The tyres of our electric pallet stackers have a smaller circumference than those of our counterbalance forklifts, because the operation sites typically offer good driving surfaces. While the ground condition is the most important selection criterion for wheels and rollers for high lift trucks, other parameters must also be taken into account:

- Noise emission

- Starting and rolling resistance

- Load capacity

- Good shock absorption (when driving through bumps, potholes or thresholds)

- Hygiene requirements

- Environmental influences such as wetness or chemicals

- Climatic conditions

- Electrical conductivity requirements

When you buy an electric stacker truck, you want the tyres to suit your area of operation. In addition, depending on the area of application and the ground being driven on, you can choose between electric stackers with single fork rollers or tandem fork rollers:

- Single-fork rollers are best used on level floors and allow easier manoeuvring than tandem rollers. However, wear on the rollers is higher than on tandem fork rollers.

- Tandem-fork rollers excel on uneven floors and in overcoming floor thresholds. The load weight is distributed over four rollers, which reduces the contact pressure and thus the wear per roller. Overall, the electric stacker truck will run more smoothly on uneven surfaces with these rollers.

The material properties of the rollers sometimes differ:

| Parameter | Polyurethane (PU) | Thermoplastic polyurethane (TPU) | Nylon |

|---|---|---|---|

| Smooth surfaces | ✔ | ✔ | ✔ |

| Moist oily surfaces | ✔ | ✔ | ✔ |

| Fragile surfaces | ✔ | ✔ | ✔ |

| Chemically resistant | ✔ | ✔ | ✔ |

| Uneven surfaces | ✔ | ✔ | × |

| Low-noise | ✔ | ✔ | × |

| Abrasion resistant | ✔ | ✔ | ✔ |

| Heavy duty | ✔ | ✔ | ✔ |

| Wear resistant | ✔ | ✔ | ✔ |

| Available for roll type |

For drive wheels, support wheels and load rollers |

Only as drive wheel |

For drive wheels, support wheels and load rollers |

Two PU wheel-variants are available on request:

- We carry antistatic PU drive wheels that discharge an electrostatic charge into the ground, preventing electrical breakthrough punctures for environments where electrical conductivity must be considered.

- Choose PU wheels coated with quartz sand for particularly smooth or slippery surfaces. These special drive wheels enable improved ground contact (traction) due to the coating, making your powered pallet stacker more effective on challenging surfaces.

12. Pedestrian operation

We have electric stackers with different operating modes, designed for both left- and right-handed users, which may suit depending on the distance lengths you need to cover:

- Walk-behind operation: In this mode, all steering and operating functions are performed by an operator walking alongside the vehicle. Electric stacker trucks used exclusively in walk-behind operation are equipped with a long, low-mounted tiller. This ensures a sufficient safety distance between the vehicle frame and the operator. When you move the tiller, the drive wheel is turned in the desired direction of travel. You can regulate the driving speed via the control elements mounted on both sides of the tiller head. Power stackers in walk-behind mode are particularly suitable for short to medium transport distances.

- Ride-on operation: With these semi electric stackers, all steering and operating functions are performed by an operator riding on the vehicle, either standing or seated in a protected operator compartment. The vehicles are equipped with a short tiller and are particularly suitable for medium to long transport distances. These models are available from us upon request.

- Optional walk-behind or ride-on operation: All steering and operating functions are performed by either a walking or riding operator. A foldable or permanently installed operator platform can serve as the workplace in ride-on operation.

Please note: In the UK, operators of powered pallet stackers with operator platforms require appropriate training as mandated by PUWER regulations, regardless of operating speed.

13. Practical functions of electric pallet stackers

Electric pallet stackers offer specialised functions that can significantly streamline your daily operations. Depending on your operational environment, some vehicle functions may even be necessary to safely navigate your storage areas.

Electric pallet stackers with initial lift

If you frequently drive over uneven floors in your warehouses, overcome floor thresholds such as drive-over plates, or manage ramp crossings and loading bridges, electric stacker trucks with additional lift are ideal. At the Jungheinrich PROFISHOP, electric stacker forklifts with ramp comfort or wheel arm lift are available for this purpose.

Both wheel arm lift functions increase ground clearance and guarantee safe travel even when driving over uneven surfaces or thresholds. The auxiliary lift capability enables navigation of inclines up to 16%, compared to just 5% maximum incline capability for standard units without auxiliary lift.

Electric pallet stackers with our double-stacking functionality feature additional outrigger lift mechanisms. These enable the pickup and handling of two pallets stacked on top of each other.

Electric wide-gauge stacker

In addition to Euro pallets, our all-electric wide-gauge stackers can also up closed load carriers. These versatile industrial trucks enable both standard and transverse pallet pickup operations: the wheel arms drive around the load unit, the fork positioned between the wheel arms is lowered to the ground, and the stacker picks up pallets in the same way as with a cantilever electric forklift.

Each vehicle features specific wheel arm spacing that determines the maximum load unit dimensions. We offer additional wide-gauge variants to accommodate different load sizes. Models equipped with ISO fork carriages (such as the EJC 110 bi E) feature adjustable fork carriages, enabling the transport of special-sized pallets.

Our wide-track models are supplied in three different versions, with outrigger spacing of 891mm, 1070mm, or a maximum of 1270mm.

The advantages of wide-gauge electric stackers:

- Pick-up of closed goods and special pallets

- Transverse pick-up of (Euro) pallets

- Forks can be lowered to the floor

- Different wheel arm distances optionally available

Models with adjustable ISO fork carriages also enable attachment mounting, making the application range of the wide-track stacker particularly flexible and versatile.

14. Individual equipment options

In addition to our wide range of electric power stacker trucks with various functions and equipment options, we also offer extensive customisation options. Additional functions include display screens, organiser functions or special drive wheels.

We also offer various mast types, different battery specifications and sizes, and the appropriate charging systems for your needs. Depending on the model, additional options include individual access systems, refrigeration or deep-freeze equipment, proportional hydraulics for particularly sensitive loads or aquamatics for simplified of lead-acid battery maintenance.

We offer electric pallet stackers with special fork lengths and widths, weighing equipment or in stainless steel design within the scope of special construction. Our competent technical advisors will be pleased to help you with your selection.

15. FAQ for electric pallet stacker

Electric stacker trucks are mostly used for regular or occasional horizontal and vertical pallet handling, especially in indoor warehouse areas. They can be used to stack and retrieve goods at medium to high rack levels. In addition, these electric stackers are ideal for transporting goods over medium to long distances, with long-distance variants featuring a driver's platform or seat for ride-on operation.

The use of electric stackers in warehouses, dispatch or sales areas offers many advantages:

- Wide range of models: Electric stackers are available in entry-level to high-performance models. This means that they can be a worthy investment for any budget - even for small companies.

- No license requirement: Drivers must however undergo proper training under UK regulations.

- Increased productivity: Electric drive increases productivity and efficiency.

- Ergonomic operation: Your employees will benefit from electric motor assistance, making work more ergonomic.

- User-friendly design: Simple and intuitive operation.

- Versatile operations: E-stackers are versatile and are used for transport, storage and retrieval, and order picking.

- Customisable solutions: There is a vehicle for every application scenario, which can be further tailored to your personal needs with individual options if required.

No, in the UK, no formal forklift license is required for electric pallet stackers. However, operators must receive proper training before first use. Under PUWER (Provision and Use of Work Equipment Regulations), employers must provide adequate instruction covering safety regulations, accident risks, equipment functions, attachments, and stability principles. While not a "license," this training is legally mandatory and should be documented.

Some electric pallet stackers can be used outdoors if they have appropriate weather protection ratings. However, these vehicles are not suitable for cold stores or freezers, applications involving condensation (as they can be damaged by moisture), highly dusty environments and oily or very wet surfaces. For such demanding conditions, robust combustion engine trucks remain the preferred choice.