Work ergonomically with scissor lift tables

Scissor lift tables allow you to raise palletised or individual goods to an ergonomic working height and even further to higher storage areas, while scissor lift platform trucks enable you to move loads over short distances. Our buying guide will help you choose the most suitable product for your needs.

1. Scissor lift tables can be operated in a variety of ways

Scissor lift tables can be indispensable tools in warehouses, intralogistics, manufacturing facilities and sales areas. They can be used to lift and lower goods onto or into various load carriers such as pallets, packaging or pallet boxes – to an ergonomic working height for back-friendly working.

There are different types of scissor lift tables available. We offer both static and mobile scissor lift tables in our UK store. They can be raised manually, electrically, or with compressed air, depending on the model. Here is an overview of the possible applications of our lift tables:

| Scope of application / tasks | Details |

|---|---|

| Workbench, worktable or assembly table |

|

| Lift for goods transport |

|

| Loading bridge and ramp system |

|

| Order picker |

|

| Integration into automated processes |

|

2. Our lifting tables in detail

The scissor lift tables and platform trucks in our range meet all required safety standards and are tested and certified according to the European Standard BS EN 1570. The equipment is exclusively made from high-quality materials such as powder-coated profile steel, solid construction or tool steel (ST52 or ST37) and is expertly processed. This makes every BARTH scissor lift table, Ameise® scissor lift table, or EdmoLift® model a reliable and safe piece of equipment with a long service life.

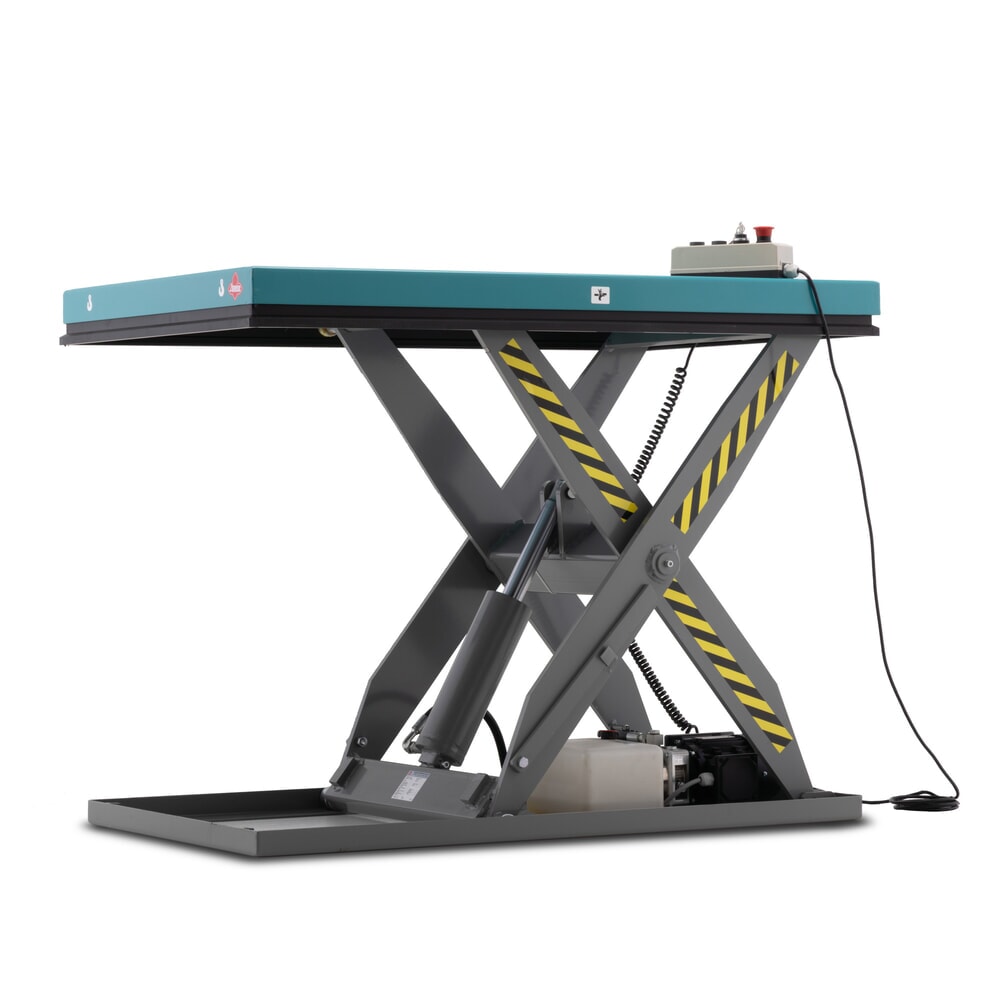

Scissor lift platforms

Our static scissor lift platform tables enable you to raise and lower loads to great heights (depending on the model). The lift platform is mounted on at least two scissor-like supports that can be bolted to the ground or installed in pits. The scissor lift platforms are available in different designs, tailored to specific applications and can be extended with accessories:

| Type of scissor lift platform | Features | Performance |

|---|---|---|

Flat scissor lift tables

|

|

|

Single scissor lift tables

|

|

|

Scissor lift platform trucks

Scissor lift platform trucks are ideal for transporting goods, tools or manufacturing parts to the workplace and for raising or lowering them to an ergonomically correct working height for order picking. Depending on the model, this can be done with a spindle, manually via a foot lever, or electrically. For easy transport, each lift truck is compact and equipped with smaller platforms than static scissor lift trucks.

Lift trucks are moved using ergonomic push handles (fixed or foldable, depending on the model) and smooth-running TPU or polyurethane rollers. The devices can be safely locked in position at the desired workplace with parking brakes. The mobile lift table is available to buy from us in these variants:

| Type of scissor lift platform truck | Features | Performance |

|---|---|---|

Manual scissor lift table trolleys

|

|

|

Electric scissor lift table trolleys

|

|

|

3. Here's how to choose a suitable scissor lift table

We offer a wide range of scissor lift tables with varying load capacity and application, lifting range, and other parameters. To find the lift table that suits your needs, consider the following important selection criteria:

- What weight capacity does the lift table need to support?

- What lifting height should the equipment be able to reach?

- What are the dimensions of the product, and what platform size is appropriate?

- Where will the lift table be placed (indoors or outdoors)?

- What types of loading methods will the equipment be used for?

- Should the scissor lift table be static or mobile?

- With what type of operation and drive function should the table operate?

- Are specific safety features required for the lift table?

Lifting capacity

To lift and, if necessary, move goods and products safely and securely on scissor lift tables, the table must be loaded only up to its specified maximum load capacity. When choosing a suitable type of lifting table, you should consider the peak loads that occur in your operation as a basis for your decision. Our scissor lift platform trucks offer a maximum lifting capacity of approximately 1000kg, depending on the model. The static scissor lift tables in our range offer a lifting capacity of up to 3000kg, making them ideal for the vertical transportation of heavy loads.

Another factor to consider when choosing a suitable scissor lift table is how the weight will be distributed on the platform. For example, a lift table with a load capacity of 1000kg may not be sufficient to hold a weight of 1000kg if the load is not evenly distributed on the platform.

This is due to the interplay of force and the lever arm: depending on where the load is located on the platform, the scissors of the lift table will be loaded differently and subject to different levels of stress. To avoid damage, DIN EN 1570-1 provides guidelines on this matter:

- If the load is evenly distributed across the entire platform, the load capacity specified by the manufacturer is sufficient. For a maximum load of 1000kg for example, a scissor lift table with a load capacity of 1000kg is the appropriate choice.

- If the load is only placed on half the platform length, the lift table must still be able to support at least half the weight of the load. Therefore, if the lift table has a load capacity of 1000kg, a maximum load weight of only 500kg can be loaded over half the platform length. Conversely, if a load weight of 1000kg is to be loaded over half the platform length, you will need to purchase a lift table with a capacity of 2000kg.

- If the load is only placed on half the platform width, the lift table must still be able to support at least one third of the weight of the load. Therefore, if the lift table has a capacity of 1000kg, a maximum load weight of only 330kg can be loaded on half the platform width. Conversely, if a load weighing 1000kg is to be regularly placed over more than half the platform width, a lift table with a capacity of 3000kg instead of just 1000kg is the right choice.

Lifting height

Whether a scissor lift table is suitable for your operational processes depends not only on its load capacity but also on its lifting height. This can vary depending on the type of scissor mechanism or the length of the scissor frame.

| Application | Lifting height by model |

|---|---|

| Lift tables primarily used as stationary workstations at ergonomic height |

Low-profile scissor lift tables: 70mm to 840mm Tilting lift tables: 190mm to 850mm |

| Lift tables used as stationary lifts for material or goods |

Single scissor lift tables (stationary worktable): 160mm to 1880mm Double scissor lift tables: 275mm to 2700mm |

| Lift tables used as mobile worktables or transport aids |

Manual scissor lift platform trucks: 220mm to 2000mm Electric scissor lift platform trucks: 370mm to 1300mm |

Loading

To load or unload goods or materials onto or from the scissor lifting platform, material handling equipment such as pallet trucks, or stacker trucks are usually used. Depending on the load weight, the conditions in your facility and the functions of the lifting table, the following options are possible:

| Loading method | Lift table type | Process description | Applicable trucks |

|---|---|---|---|

| Direct entry |

Low-profile scissor lift table with U-shape |

The truck is driven directly into the U-shaped recess of the lift table platform. The load carrier can then be easily and safely lowered and set down over the platform. |

|

| Loading or unloading via ramp |

Low-profile scissor lift table with closed platform |

These lift tables offer a closed platform, which means the fork tines of pallet trucks or forklift trucks cannot drive in directly. Instead, it is possible to approach the platform via a stable drive-up wedge and remove or set down goods. |

|

| Loading or unloading with wide-aisle stacker trucks |

|

Wide-aisle trucks have a greater fork spacing than standard versions. For lift table models with platforms that are no wider than 800mm, the fork tines of wide-aisle trucks can simply drive in to the left and right of the lift table and set down or pick up palletised goods directly over the platform. |

|

| Barrier-free loading or unloading |

Scissor lift table with pit installation |

To reach the platforms barrier-free with a truck, many of our stationary lift table models are also suitable for pit installation. Here, the ground and platform are at the same level and can also be loaded and unloaded with pallet trucks. |

|

Mobile or stationary use

Scissor lift tables can be used either mobile or stationary depending on their design. The main difference lies in the load capacity and achievable lifting heights. Mobile scissor lift tables have smaller platforms and a lower load capacity than static scissor lift tables. They also usually do not reach the same lifting heights as static models. However, they can be easily moved over short distances and thus offer versatile application possibilities.

In contrast, static lift tables can be installed permanently on the ground or in pits. As these models can handle high load capacities and lifting heights, heavy loads or even material handling equipment can be transported vertically using them.

| Lift table type | Areas of application |

|---|---|

Mobile scissor lift table

|

|

Static scissor lift table

|

|

Lifting function

At Jungheinrich PROFISHOP, you can buy scissor lift tables with various lifting drives. The drive system suitable for your operation depends on the load capacity, tasks, and application area required of the lift table. Depending on the drive system, there are various advantages and disadvantages for each lifting function:

| Lifting function | Functionality and equipment details | Advantages | Disadvantages |

|---|---|---|---|

| Spindle drive |

|

|

|

| Pneumatic drive (compressed air) |

|

|

|

| Hand and foot hydraulic scissor lift table drive |

|

|

|

| Electric-hydraulic drive |

|

|

|

Safety features for safe work

Each of our scissor tables is equipped with these safety features depending on their intended use and individual requirements:

| Safety equipment | Characteristics |

|---|---|

| Emergency stop function |

The switch is attached to the control unit: when it is flipped, all operations and the power supply are immediately interrupted. |

| Safety contact strip |

The strip is located on the underside of the platform and triggers when touched as this means the specified foot space has not been maintained. When triggered, lifting or lowering is stopped immediately. |

| Pressure relief valve for pneumatic and hydraulic lift drives |

Overpressure is automatically dissipated via the valve: This prevents damage or leaks to adjusting screws, lines or hoses. |

| Heat protection for electric drive systems |

The heat protection function prevents electrical systems from overheating and thus avoids short circuits or cable fires. |

| Key switch |

A lift table with a key switch can only be operated by inserting a key. This means that the device can only be put into operation by authorized personnel. |

4. FAQ on lifting tables

Scissor lift tables allow goods to be lifted and lowered on or in various load carriers such as pallets, containers or boxes, as well as individually. They are available as static scissor lift tables or mobile scissor lift platform trucks. The advantages of using these lifting platforms lie primarily in their versatility and model-dependent diverse applications:

- Work ergonomically at customiseably adjustable working heights

- Use as a (mobile) workbench or worktable

- Use for lifting goods or materials for material supply, e.g., to conveyor belts or for loading and unloading racks and shelves

- Can be used as a replacement for loading bridges and ramp systems

- Integration into automated processes possible

Lift tables must always comply with the applicable safety requirements according to the Lifting Operations and Lifting Equipment Regulations 1998 (LOLER). Thorough examinations of the lifting equipment should be carried out in a number of situations including, before first use, during and after reinstallation, and in cases where the table is exposed to weather conditions that could cause deterioration. Depending on the type of lifting table and its area of application, the following safety features are also recommended:

- Dead man's switch

- Emergency stop function

- Safety contact strip

- Slip-resistant tear plate

- Catch devices

- Pressure relief valve

- Heat protection for electric lifting drive

Scissor lift tables should undergo regular maintenance to ensure that they are safe to use and in working order. The Provision and Use of Work Equipment Regulations 1998 (PUWER) requires that all lifting equipment be maintained in an efficient state and in good working condition. Although a machinery maintenance log is not required, it is recommended that one is recorded and kept up to date. Lift table operators should carry out daily and monthly maintenance work depending on frequency of use:

- Daily visual inspection: All hydraulic or pneumatic parts are examined for leaks, leakages or visible damage.

- Monthly maintenance: All safety devices of a lift table are checked for functionality. In addition, the oil level of the hydraulic unit is checked and topped up if necessary. The hydraulic oil temperature must be within the prescribed range.

Which maintenance work is important for a lift table is also listed in the equipment's operating instructions. There you will also find further information on recommended maintenance intervals for the specific equipment.