Selecting the right mobile scissor lift table

Mobile scissor lift tables are ideal aids for moving goods, tools or production parts to where they are needed, and for lifting or lowering them to an ergonomically correct working height for order picking. In contrast to the scissor lift platforms in our range, the mobile platform lifts can be moved. Some of the mobile devices have smaller platforms and a lower load capacity and lifting height than the stationary scissor lift tables. Mobile elevated work platforms can be moved smoothly over short distances and therefore offer a wide range of applications – including as worktables and workbenches at a back-friendly working height.

The mobile scissor lift tables are usually equipped with ergonomic push handles and smooth-running TPU or polyurethane castors. Depending on the lifting height and load capacity, the devices are equipped with single or double scissors. For particularly hygiene-focused environments – such as in food processing plants – we also offer scissor lift platform trucks made of corrosion-resistant stainless steel.

The mobile scissor lift tables in our range comply with all required safety standards and are tested and certified in accordance with BS EN 1570-2 of the European Committee for Standardisation (CEN). The devices are made exclusively from robust materials and have a high-quality finish.

1. Select a mobile scissor lift table with the right load capacity

In order to lift and lower goods safely and stably with mobile lift tables, the devices may only be loaded with the specified maximum load. When selecting a suitable mobile scissor lift platform, you should therefore base your decision on the peak loads that occur in your operations. The scissor lift platform trucks in our range offer a load capacity of up to 1000 kg, depending on the model.

When selecting a truck mounted scissor lift with a suitable load capacity, the most important factor is how the weight is distributed on the platform. This is due to the interplay between the force and lever arm: Depending on where the load rests on the platform, the scissors of the device are loaded to different degrees. To prevent damage, BS EN 1570-2 specifies the following:

| Load | Suitable load capacity |

|---|---|

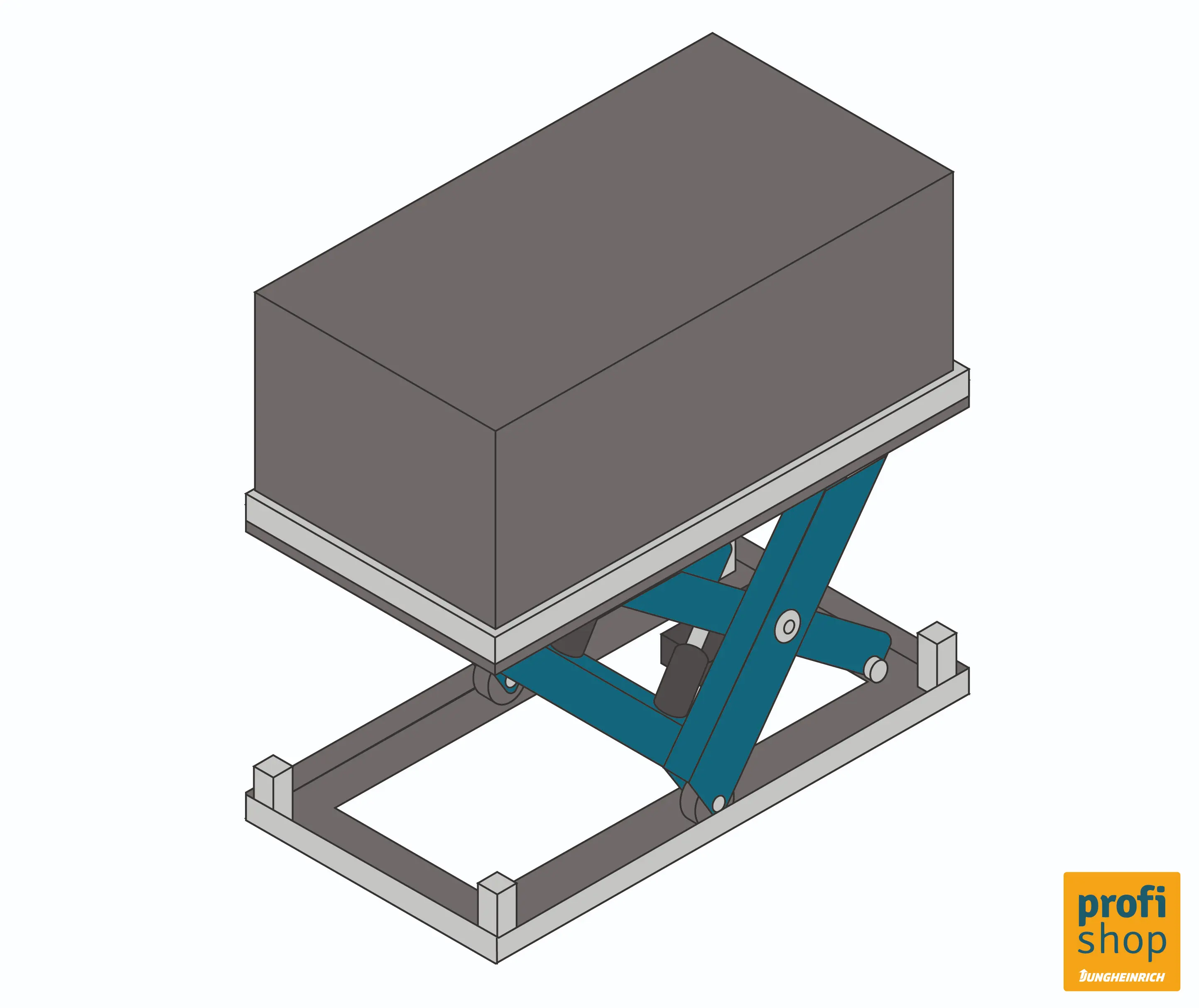

Uniform load

|

If the entire platform is loaded evenly, the load capacity specified by the manufacturer is sufficient. For example, for a maximum load of 500 kg, a mobile scissor lift table with a load capacity of 500 kg is the right choice. |

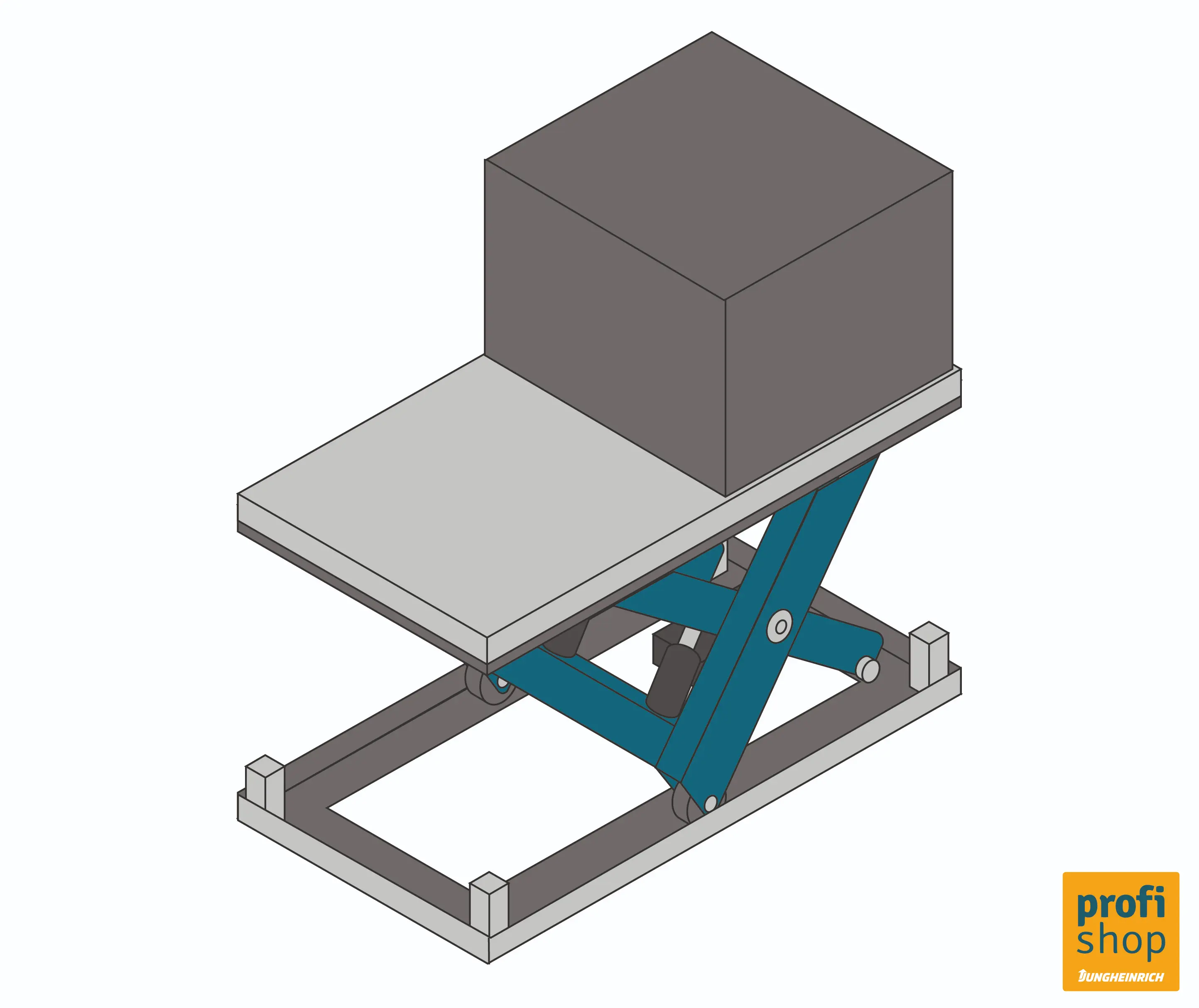

Load on half the length

|

If the load is only placed on half of the platform length, the mobile scissor lift table must still be able to carry at least half of the load weight. So, if the model has a load capacity of 500 kg, only a maximum load weight of 250 kg may be loaded over half the platform length. Conversely, this means that if a load weight of 500 kg is to be loaded over half the platform length, a model with a load capacity of 1000 kg is required. |

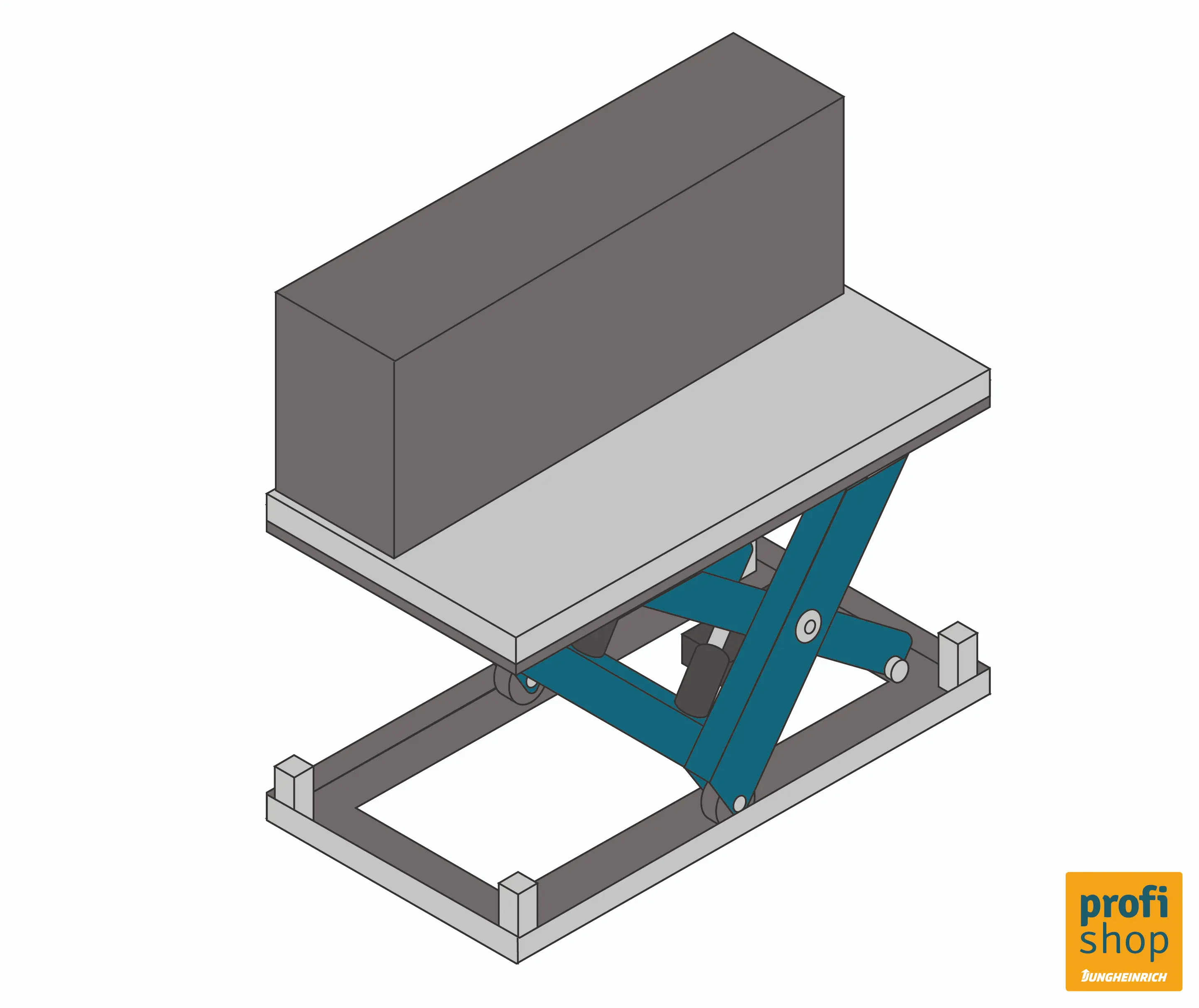

Load on half the width

|

If the load is only placed on half the platform width, the mobile lift table must still be able to carry at least a third of the load weight. For instance, if the unit has a load capacity of 500 kg, only a maximum load weight of 166 kg may be loaded on half the platform width. |

2. Consider sufficient lifting height

Whether a scissor lift platform truck fits into your operating processes depends not only on the load capacity but also on the lifting height. This can vary depending on the type of scissor frame or the length of the scissor tongs. At Jungheinrich PROFISHOP, you can buy lift table trucks with the following lift heights:

| Scissor type | Lifting range (minimum and maximum lift height) |

|---|---|

Single scissor

|

210–1400 mm |

Double scissor

|

340–1800 mm |

3. Buy a mobile scissor lift table with the right lifting function

Depending on the model, our mobile lift tables offer three different lifting functions, which should be selected depending on the weight of the loads to be transported and the frequency of lifting operations:

| Lifting function | Details | Available for |

|---|---|---|

| Spindle |

|

|

| Hydraulic |

|

|

| Electro-hydraulic |

|