Shelf racks for industry, warehouses, and workshops

Industrial shelf racks are ideal for storing small and medium-sized goods. These expandable storage systems are customisable and thus make versatile solutions for your space. Our buying guide will help you find the perfect shelf racks for your needs.

1. What are shelf racks and what advantages and disadvantages do they have?

Shelf racks are heavy-duty shelving units that are particularly versatile for use in warehouses, workshops, or retail spaces. Steel shelf racks can clearly and safely store small and medium-sized items such as sales goods, accessories, storage containers or tools. Depending on the model, these industrial shelf racks can support loads of up to 500 kg.

Shelf racks consist of a base bay that can be used as standalone storage but can also be extended with one or more add-on bays and matching shelves. This allows you to adapt your shelving units to almost any space and extend them as required. Shelf racks are ideal for making the best possible use of the available space, particularly in warehouses with a high turnover rate or when you don’t yet know the expected warehouse load.

Jungheinrich industrial shelf racks offer the following advantages and disadvantages:

| Advantages | Disadvantages | |

|---|---|---|

|

|

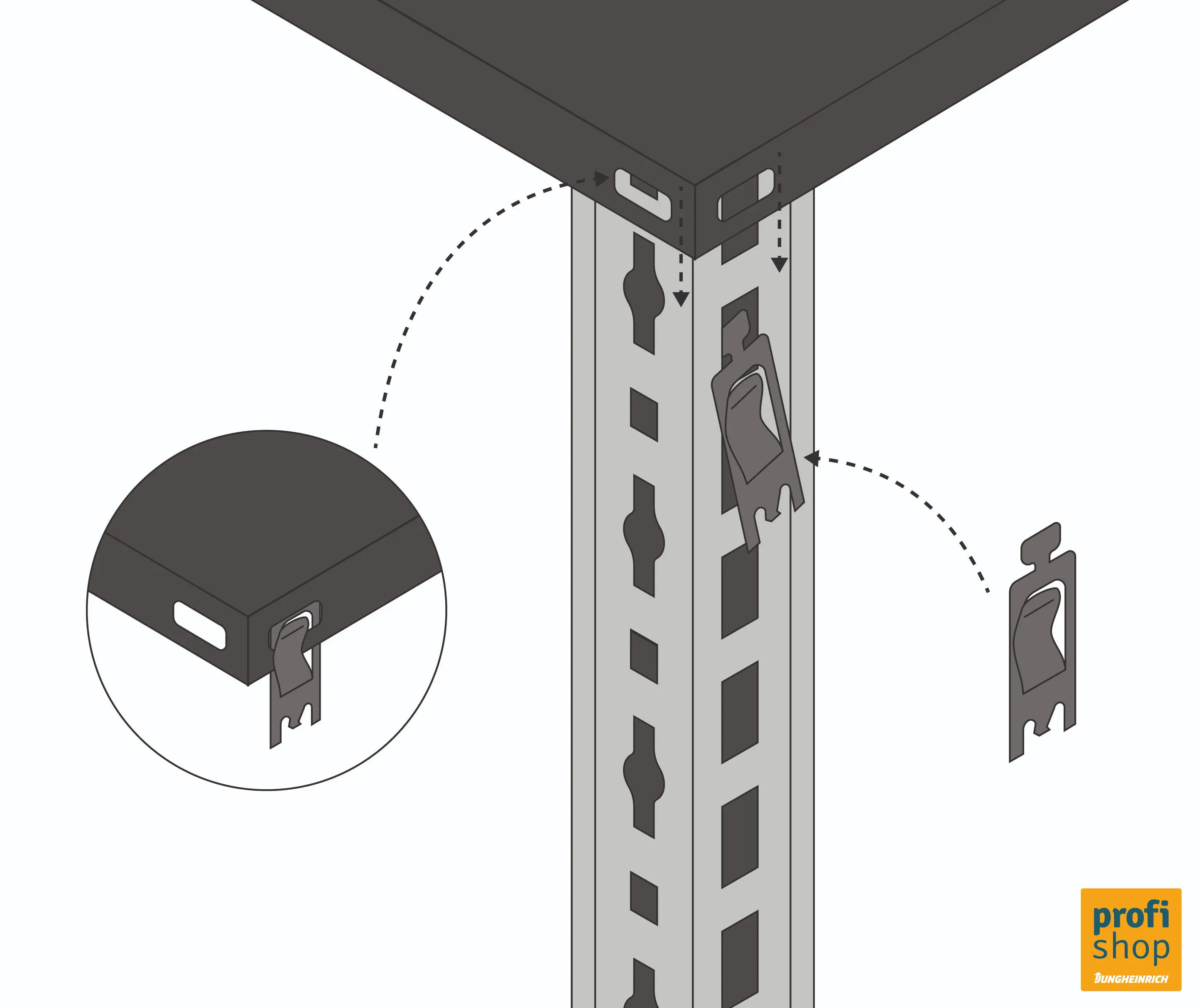

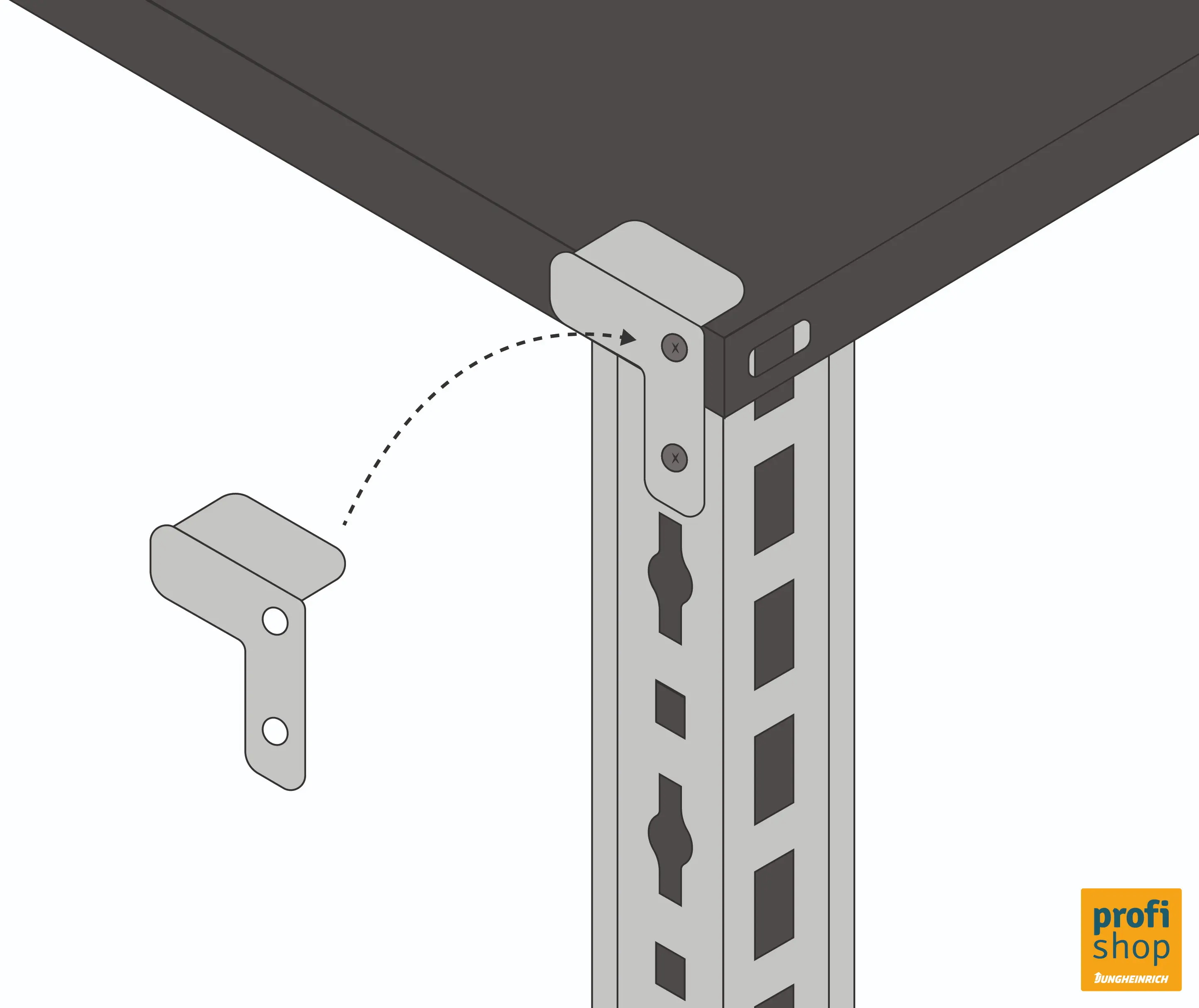

2. Shelf racks in plug-in or screw system

We offer shelf racks in both screw and plug-in systems. An advantage of both variants is that they can be quickly assembled and easily extended with matching add-on units, shelves and other accessories. Regardless of their assembly type, all our shelf racks have punched holes in the frame elements, so shelves can be inserted there in 25mm increments.

However, when selecting suitable industrial shelf racks, it is likely that one assembly system will be the best fit:

| Parameter/Assembly System | Plug-in system | Screw system |

|---|---|---|

|

| |

| Assembly |

|

|

| Bracing |

|

|

| Advantages |

|

|

| Suitable for |

|

|

3. How to find the right warehouse racking system

To ensure that your steel shelf racks perfectly match your warehouse or storage needs, you should consider some important criteria when choosing individual components.

Bay type

We stock both basic shelving bays and matching add-on units for existing warehouse shelf rack systems in our online shop:

| Bay Type | Components | Use |

|---|---|---|

Basic bay

|

|

|

Add-on bay

|

|

|

Load capacity

The shelf racks’ load capacity depends on the material thickness of the shelves, the material of the frame and the strength of the connecting elements. The base and add-on units are usually made from robust, galvanised steel. Heavy-duty shelves made of tubular steel or galvanised quality sheet metal can withstand even heavy loads, provided the load is distributed evenly.

Additional features such as support beams, diagonal bracing or lining the shelves with steel panels can further increase your warehouse racking’s load-bearing capacity. You can determine whether your desired warehouse shelf rack unit has the right load-bearing capacity using two values:

- Shelf load: The maximum permissible weight with which a single or continuous shelf level can be loaded.

- Bay load: The permissible maximum weight with which the entire shelf bay (basic or add-on bay) can be loaded (without its own weight).

Please note: Even if your individual shelves can each handle their maximum load, the overall racking unit may have a lower total capacity. Always consider both the individual shelf loads and the maximum unit load to ensure safe operation.

Under certain circumstances, some warehouse racking solutions may legally require impact protection. We offer impact protection solutions for many different shelf legs and corners.

Access

Our industrial shelf racks can be set up with single-sided or double-sided access to stored goods. Depending on the goods to be stored, the storage strategy and the size and layout of the storage space, you may benefit from one or both of the access options available:

| Access / parameters | Set-up | Shelf rack system | Applicable for storage strategy |

|---|---|---|---|

Single-sided access

|

|

|

|

Access from both sides

|

|

|

|

Mobility

In addition to stationary shelf racks, we also offer mobile versions for maximum flexibility:

- Equipped with four castors for easy movement

- Accessible from both sides through the open compartments

- Available with either three or five shelves

- Shelf load up to 300 kg with compact dimensions

- Ideal for changing workplaces, temporary storage or mobile order picking

Mobile shelf racks are particularly suitable for businesses with flexible storage requirements or when racking needs to be used at different locations.

4. FAQ for shelf racks

Heavy duty warehouse shelving is suitable for various storage strategies because it is very flexible. Industrial shelf racks are ideal for both first-in-first-out (FIFO) and last-in-first-out (LIFO) storage methods – which principle works best depends on the shelving structure. Shelving with single-sided access works on the LIFO principle, where the last items stored are the first removed. Double-sided access shelving enables FIFO storage, where goods are loaded on one side and picked from the other.

The shelf load of a shelf rack shows the maximum weight an individual shelf can handle - as long as goods are spread evenly across it. In contrast, the bay load shows the maximum weight the entire racking unit can safely carry.

Shelf racks are either screwed or plugged together into one unit. With the screw system, all parts are securely fastened with screws. With a plug-in system, all parts simply slot into each other. This offers greater flexibility and allows quick dismantling or reconfiguration when needed. Regardless of the assembly method, shelving units consist of a basic section (frame plus shelves) which can be extended with add-on sections as required. This way, you can create entire rows of shelving to fit your available space.