Scissor lift platforms for material lifting in warehouses and production

Scissor lift platforms make it easy to lift palletised or individual goods to an ergonomic working height or to higher storage areas. Depending on the model and function, these electric lift platforms can also be a practical addition to an automated process in a warehouse or industrial building. Use our buying guide to find the right scissor lift platform for your needs.

1. Scissor lift platforms for versatile use in industrial processes

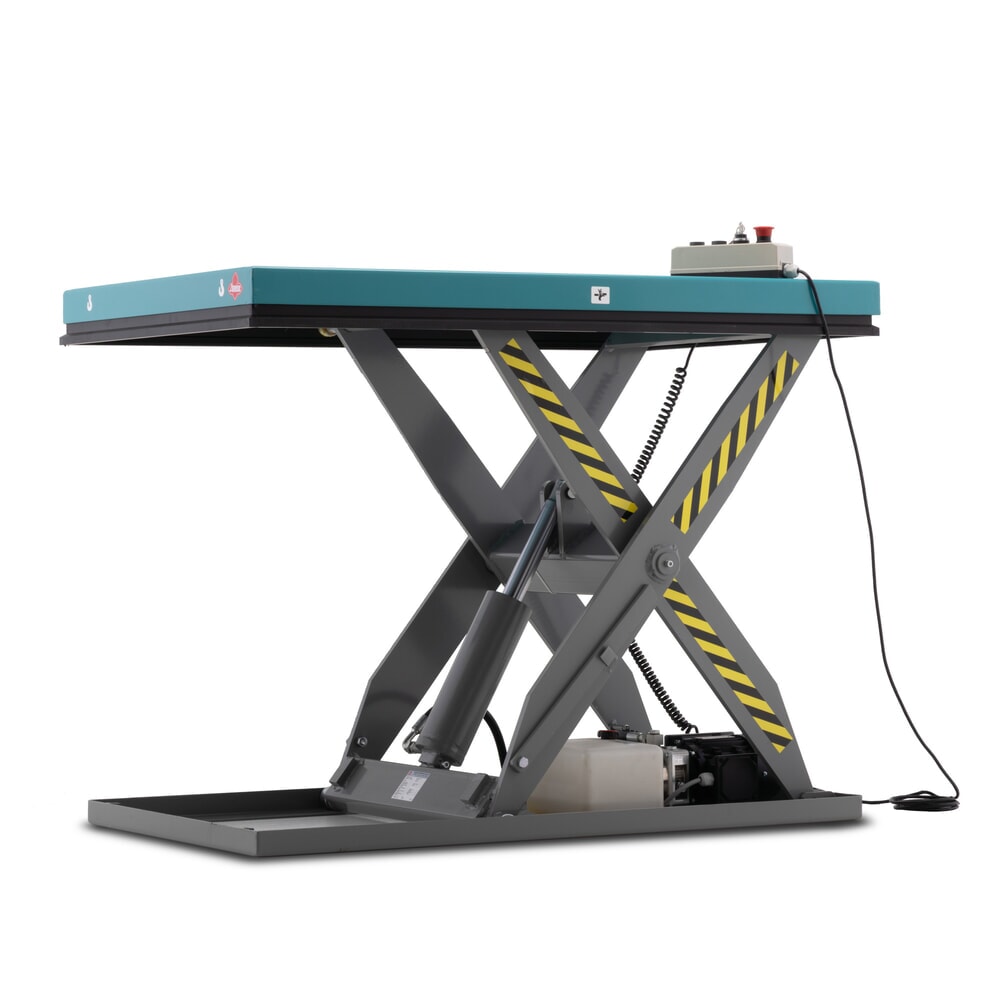

The scissor lifts available from Jungheinrich PROFISHOP enable you to lift loads on or in load carriers such as pallets, outer packaging or pallet boxes to ergonomic working heights of up to 2,700mm and higher, depending on the model. The scissor lift platform – also known as a electric lift platform – Is mounted on at least two scissor-like beams, which can be bolted to the floor for a floor mounted scissor lift or installed in pits.

Unlike mobile scissor lift tables, scissor lift platforms are designed for stationary use. However, some devices are portable and can be picked up and relocated using crane lifting eyes or fork pockets for pallet trucks.

An overview of the possible applications for our scissor lift platforms:

| Area of application | Details |

|---|---|

| Ergonomic work processes |

|

| Use as workbench or worktable |

|

| Replacement for dock levellers and ramp systems |

|

| Integration into automated processes |

|

We stock scissor lift platforms in various designs tailored to specific applications and expandable with accessories.

Regardless of type and design, all scissor lift platforms in our range comply with the required safety standards and are tested and certified according to BS EN 1570-1. All devices are manufactured from durable steel with powder-coated finishes for long-lasting protection, featuring robust scissor bracing and built to exacting standards.

2. What types of scissor lift platforms are there? Our models at a glance

| Scissor lift table type | Application | Technical details | Safety features & Extras | Platform & loading |

|---|---|---|---|---|

Flat scissor lift tables

|

Ideal for easy access with floor conveyances and as stationary worktables |

|

|

|

Single scissor lift tables

|

Versatile use as a stationary worktable, goods lift or material lift |

|

|

|

3. How to choose the right scissor lift platform for your needs

In our range you will find a large selection of different scissor lift platforms which differ in their lifting range, load capacity and other parameters. To find the equipment best suited to your needs, you should consider some important selection criteria:

- What weight capacity should the lift platform have?

- What lifting height or lifting range is required for your work tasks?

- What are the dimensions of the product and which platform size is suitable?

- Where will the scissor lift be set up (indoors or outdoors)?

- How will the scissor lift be loaded?

- Which drive should be used for the lifting function?

- Are certain safety features required?

Consider load-bearing capacity

To safely and stably lift and lower goods and merchandise, a scissor lift platform may only be loaded with the specified maximum load. When selecting a suitable model, you should therefore use the peak loads that occur in your operating workflow as the basis for your decision. The floor mounted scissor lift platforms in our range offer a load capacity of up to 3,000 kg, depending on the model.

When choosing a lifting platform with a suitable load capacity, it is particularly important to consider how the weight is distributed on the platform. For example, a scissor lift platform with a load capacity of 1,000kg may no longer be sufficient for a load weight of 1,000kg if the load is not evenly distributed on the platform. This is due to the interaction of the force arm and the lever arm. Depending on where the load is placed on the platform, the scissor mechanics of the device are subjected to different degrees of stress. To prevent damage, BS EN 1570-1 specifies the following:

| Load distribution on the platform | Appropriate load capacity |

|---|---|

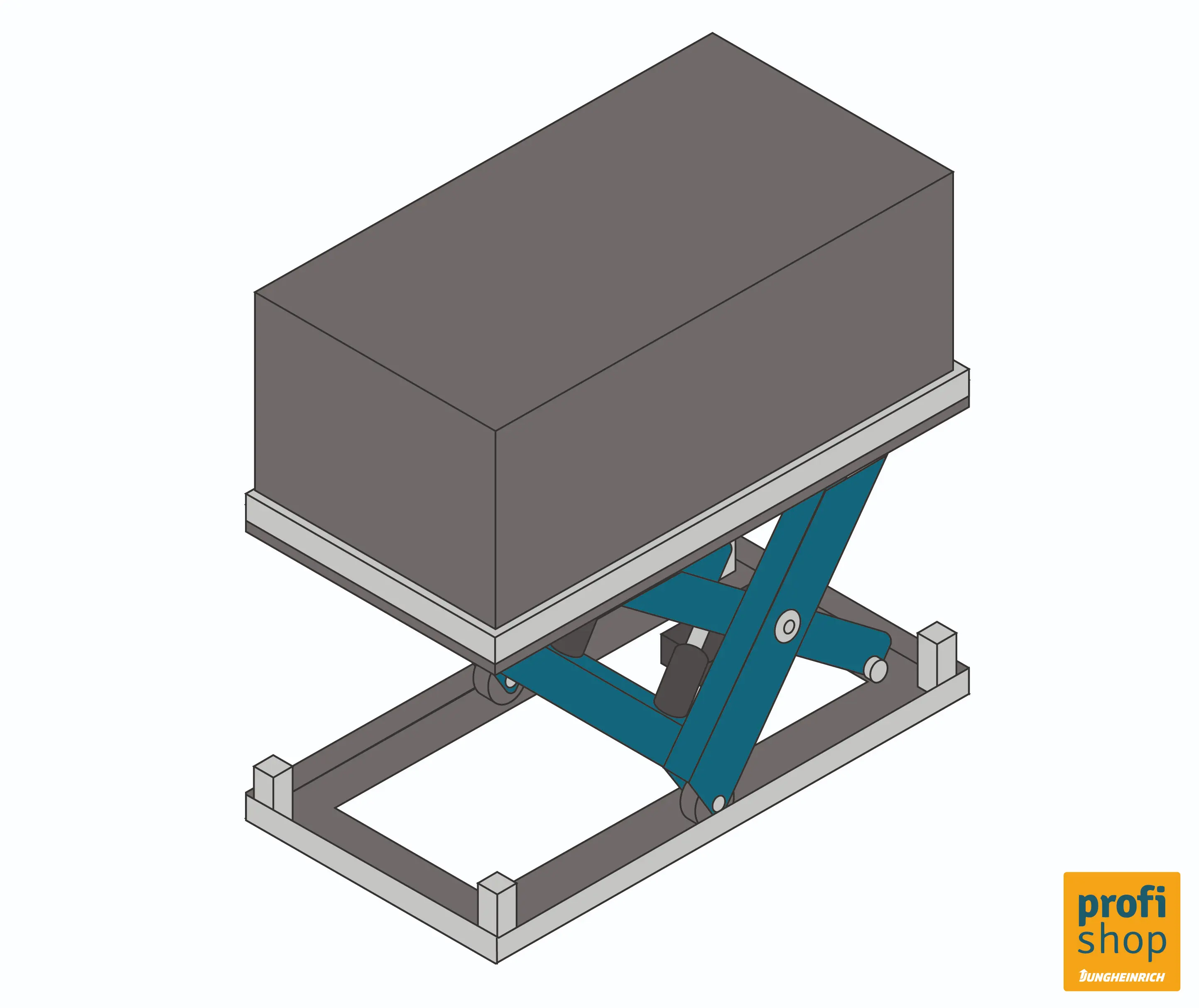

Even loading

|

If the entire platform is loaded evenly, the load capacity specified by the manufacturer is sufficient. In this case, a maximum load of 1,000kg, for example, is suitable for a scissor lift platform with a load capacity of 1,000kg. |

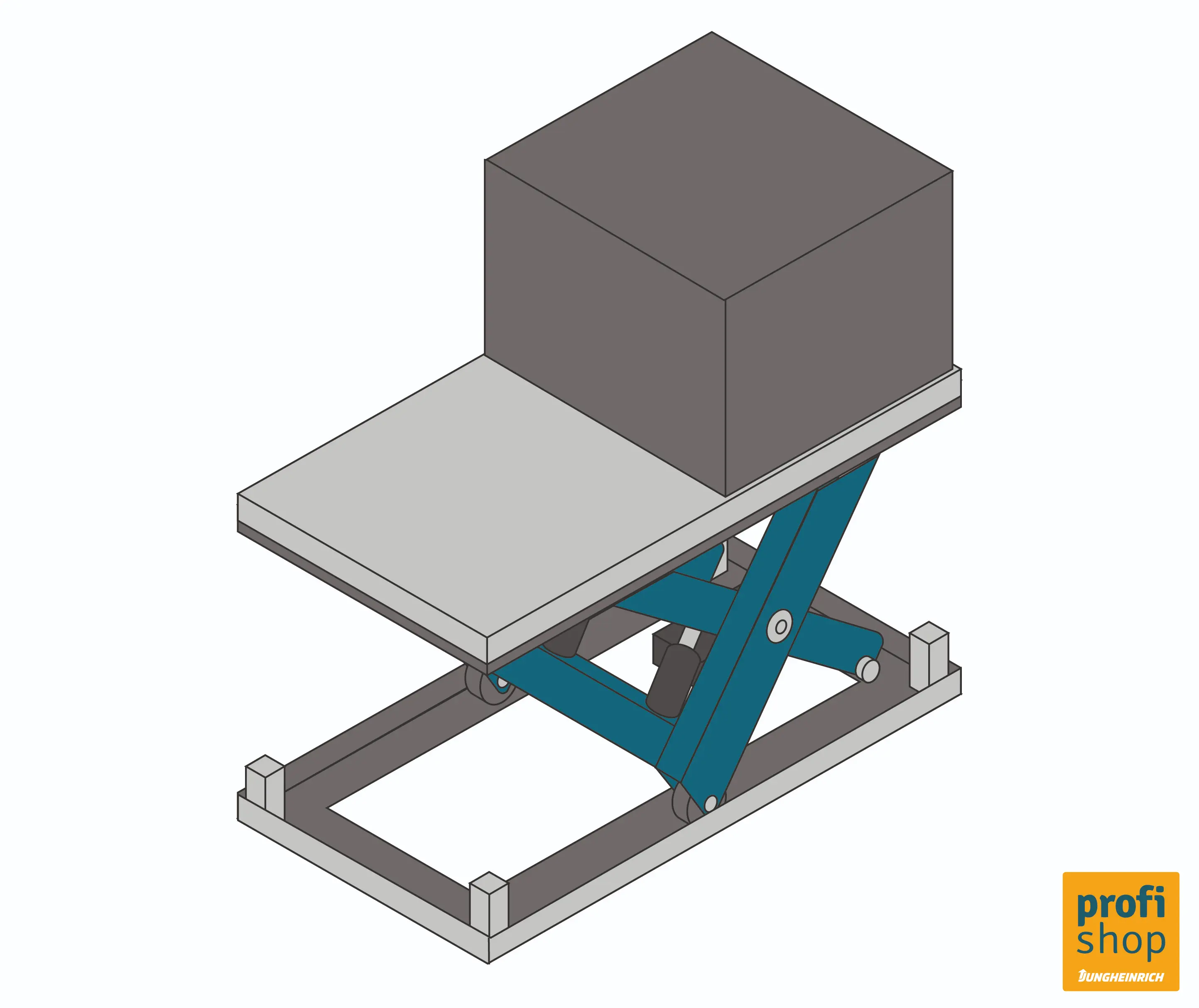

Loading over half the length

|

If the load is only placed on one half of the platform, the scissor lift must still be able to carry at least half the load weight. For example, if the scissor lift platform has a load capacity of 1,000kg, only a maximum load weight of 500kg may be placed over half the platform length. Conversely, this means: if a load weight of 1000 kg is to be placed over half the platform length, a model with a load capacity of 2,000kg is required. |

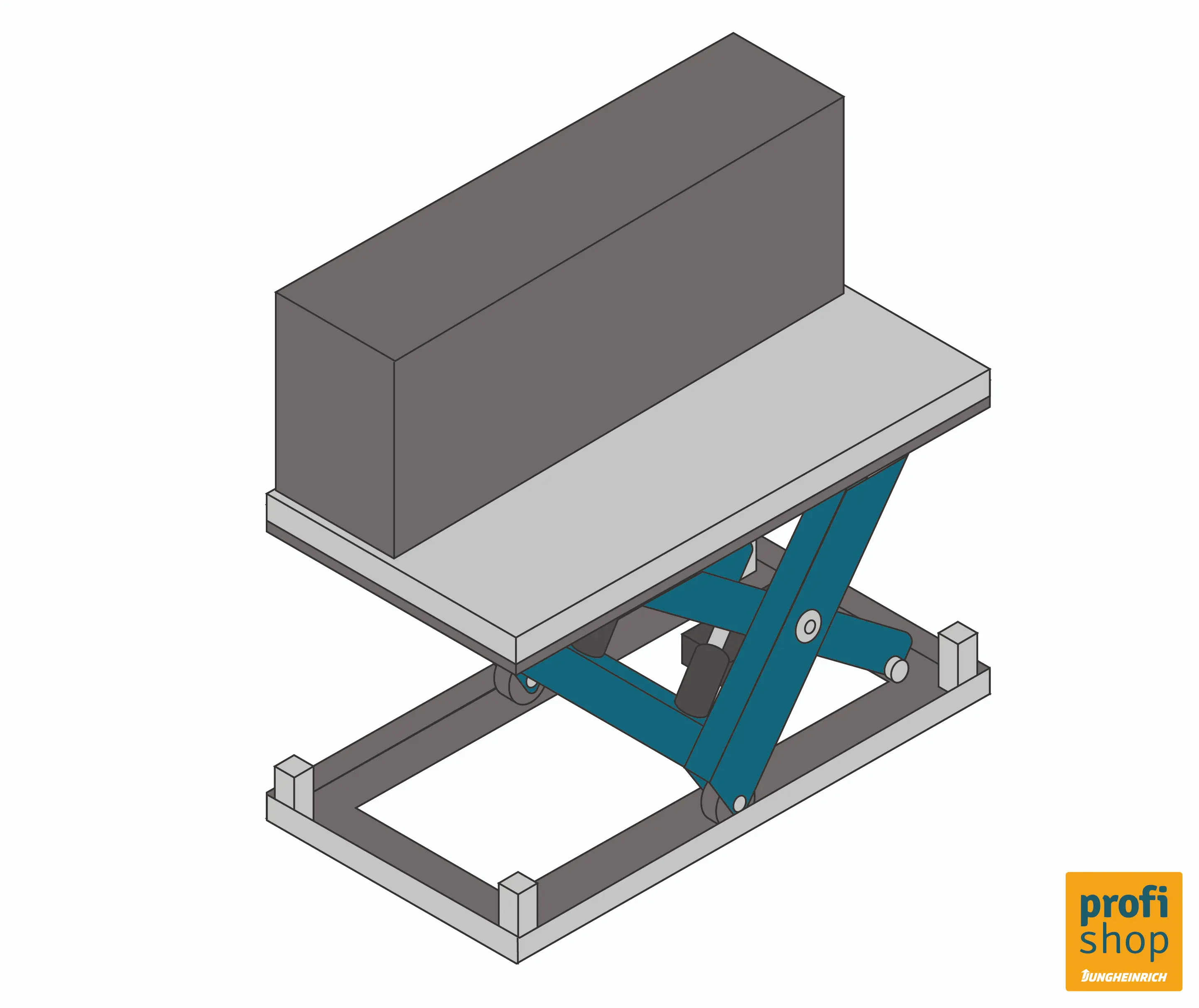

Loading over half the platform width

|

If the load is only placed over half the platform width, the scissor lift must still be able to carry at least one third of the load weight. As an example: if the unit has a load capacity of 1,000kg, only a maximum load weight of 330kg may be loaded on half the platform width. Conversely, this means if a load weighing 1,000kg is to be placed across half the platform width, a model with a load capacity of 3,000kg is the right choice. |

Determine lifting height

Whether a large or small lifting platform fits into your operating procedure depends not only on the load capacity but also on the lifting height. This can vary depending on the type and length of the scissor frame and arms. At Jungheinrich PROFISHOP you can buy scissor lift platforms with the following configurations:

| Scissor configuration | Lifting range |

|---|---|

| Flat scissor lift platform |

|

| Single scissor lift platform |

|

Installation site

The electric lift platforms available in our store are suitable for use in dry indoor areas. However, some designs also allow use in damp or corrosive indoor areas or outdoor areas exposed to the weather. Retrofittable bellows for pallet positioners also provide effective protection against dirt and moisture when the devices are temporarily used in damp indoor or outdoor areas.

Find the scissor lift platform to suit your loading method

- Industrial trucks such as pallet trucks, stacker trucks or forklift trucks are typically used to load or unload goods onto the scissor lift platform. Depending on the load weight, the surrounding environment and the lifting platform model, the following options are possible:

- Direct entry with stacker or pallet truck: Here, the industrial truck is driven directly into the U-shaped recess of the scissor lift platform. The load carrier can then be conveniently and safely lowered and set down over the platform.

- Loading or unloading via drive-on wedge: These scissor lifts have a closed platform, which prevents the forks of a pallet or stacker truck from driving into them directly. Instead, it is possible to drive up to the platform and remove or set down goods via a stable drive-on wedge.

- Loading or unloading with wide-gauge industrial trucks: The fork spacing on wide-gauge stacker trucks is greater than on standard versions. Scissor lifts with platforms no wider than 800mm enable the forks of a wide-gauge truck to easily move to the left and right of the unit and place or pick up the palletised goods directly over the platform.

- Pit installation: To access the platforms barrier free with industrial trucks, many of our scissor lift platforms are also suitable for pit installation. This allows the base and platform to be at the same height and loaded and unloaded with pallet trucks.

Lifting functions of your scissor lift platform

The scissor lift platforms in our range are powered by electro-hydraulic drive systems, offering smooth and controlled lifting and lowering of heavy loads.

| Lifting function | Operation and equipment details | Advantages | Disadvantages |

|---|---|---|---|

| Electro-hydraulic drive |

|

|

|

Safety features for a secure work environment

Depending on the model you choose, the electric lift platforms in our range are available with the following safety features:

| Safety feature | Details |

|---|---|

| Dead man’s switch |

The raising and lowering movement only occur when the corresponding switch on the control unit is continuously pressed. |

| Emergency stop function |

The emergency disconnect switch is attached to the operating unit: when pressed, all movements are immediately interrupted, as well as the power supply if necessary. |

| Safety contact strip |

The foot protection contact strip is located on the underside of the platform and triggers when touched if the specified foot clearance is not maintained. When triggered, the lifting or lowering movement is stopped immediately. |

| Safety catch device |

In the event of a drive train defect, a hydraulic safety cylinder catches the raised load platform. |

| Pressure relief valve for hydraulic lift drive |

Excess pressure is automatically released via the valve. Damage or leaks to adjusting screws, lines or hoses are thus prevented. |

4. FAQ for scissor lift platforms

Lift platforms can be used to lift and lower goods or merchandise. For stability during operation, lift tables are available as stationary equipment that can be fixed to the ground or lowered into a pit. Specific advantages of lift tables lie primarily in their wide range of application (depending on the model). They can be used:

- For ergonomic working at individually adjustable working heights

- As a workbench or worktable

- As a goods lift for material supply to e.g., conveyor lines or for loading and unloading shelves

- As a practical replacement for dock levellers and ramp systems

- Within automated processes

Scissor lift platforms can be extended with various accessories. Bellows, for example, provide additional work and corrosion protection: they are attached to the lift frame of the pallet lift table and prevent dirt or moisture from attacking the scissor construction or the drive unit. Fork pockets or foot frames are also available specifically for pallet positioners: these allow the stationary scissor lift platforms to be moved with a pallet truck or forklift truck.

In principle, large and small scissor lift platforms can be used for lifting and lowering pallets – as long as they have a sufficiently large platform and a suitable load capacity. However, lifting and lowering palletised goods is particularly ergonomic with flat scissor lifts: the forks of pallet or stacker trucks can be inserted into the recesses of the U- and E-shaped platforms of flat scissor lifts and loads can thus be lowered directly above the platform.