Industrial shelving for warehouses, workshops and offices

Whether in industrial facilities, workshops or private households, storing goods and tools safely and accessibly is simple with quality heavy-duty shelving. Find out which model is best suited to your needs in our comprehensive buyer's guide.

1. What are industrial shelving units and what advantages do they offer?

Heavy-duty shelving and racking systems are designed to store loads of up to several tonnes. The shelving systems are extremely robust and stable, as their framework is generally made of galvanised or powder-coated metal. Structurally, the beams of industrial racking systems are assembled using plug-in systems or screw connections, and depending on the model, the individual tiers can offer additional storage options – from shelves to support arms to mesh baskets and material boxes.

Vertical industrial storage racks and shelving for bulky goods are also available. You can also use them to place materials safely and appropriately - or to present goods optimally for customers in wholesale and retail. Heavy-duty shelving units in the modular plug-in assembly system are also easily expandable. With our high-quality modular components from Jungheinrich PROFISHOP, for example, you can create heavy-duty hybrid systems of pallet racks and wide span shelves in no time at all. Heavy-duty racking variants are also available for indoor and outdoor use.

2. What types of heavy-duty industrial shelving units are available?

Depending on the nature of your storage space and the type of goods to be stored, we offer heavy-duty shelving and racking systems in various design variants:

| Shelving Type | Application Areas | Push-In System | Screw System | Wire Baskets | Boxes |

|---|---|---|---|---|---|

| Wide-Span Shelving |

Industry, craft workshops, workshops, retail and wholesale trade, production halls, warehouse logistics, for indoor areas |

× | × | × | × |

| Shelf Racking |

Craft workshops, workshops, retail and wholesale trade, private households, for indoor areas |

× | × | × | × |

Wide-Span Shelving

Due to the open tubular steel construction, you can safely store heavy and voluminous goods on several levels using wide-span shelving racks. For example, with our META brand models, you always have an overview of materials and goods stored, and you can retrieve items from both sides. Heavy, voluminous, and bulky items can be safely stored on the long industrial metal shelving that spans over several levels with a shelf load of up to 1,000kg.

| Shelving Type | Features | Advantages | Disadvantages |

|---|---|---|---|

Wide-Span Shelving

|

|

|

|

Shelving Units

Flexible shelf racks with a maximum shelf load of 500kg are ideal for small and medium-sized goods. The open industrial racks can be loaded with materials on both sides. The heavy-duty racking systems from Hemmdal or Steinbock can either be flexibly assembled or firmly bolted together. These shelving systems can also be individually extended with additional shelves and add-on bays.

| Shelving Type | Features | Advantages | Disadvantages |

|---|---|---|---|

Shelving Units

|

|

|

|

Heavy-duty shelving with boltless systems

Most types of heavy-duty racks for warehouses and logistics centres are available with boltless systems for easy and quick assembly. Despite not requiring screws, industrial racks with innovative boltless or plug-in systems offer very high rigidity, stability and a strong construction.

| Shelving Type | Features | Advantages | Disadvantages |

|---|---|---|---|

| Heavy-duty shelving with plug-in system |

|

|

|

The video below compares the plug-in system with the bolt system:

3. Accessories for industrial racking systems

There are numerous accessories for industrial shelving and storage racks available from Jungheinrich PROFISHOP.

Depending on your needs, safety elements can be retrofitted to shelving systems to ensure maximum employee safety. Accessories, such as impact protection, can help safeguard racking structures by calling attention to them and protecting against accidental vehicle collisions. Marking systems, such as retroreflective warning marking tape, is another practical accessory that can serve for increased safety structures in the workplace.

| Accessory Part | Functional Properties |

|---|---|

Impact Protection

|

|

Marking systems

|

|

4. How to choose the right industrial tracking system

Before purchasing heavy-duty shelving for your warehouse or commercial space, basic questions should be clarified in order to identify the units that best fit your needs. In addition to the location and the type of goods to be stored, the type of shelving system and the materials used are of safety-relevant importance. Firstly, you should correctly calculate the available storage space and the loads to be moved beforehand. This way you can be sure that your industrial shelving units are safe to use, and that the shelving system passes the safety inspection.

Size, type and weight of the stored goods

The nature of the goods to be stored determines, among other things, the dimensions and design of your industrial racks and shelving system. It is therefore important to consider these five basic points in advance:

- Are you handling loose materials, or will they be stored in boxes?

- Are the goods excessively long or wide?

- What is the weight of the individual goods or bulk packaging? For this purpose, it can be helpful if you add up the quantity of the desired stock. This will give you the necessary maximum bay load required.

- Is your product range clearly delineated or are you planning to add other goods with possibly different dimensions or characteristics to your range?

- Do you want to operate the racks manually or with machines?

Indoor or outdoor location

Whether you require heavy-duty racking systems for indoor or outdoor use, there are various criteria to consider:

| Indoor | Outdoor | |

|---|---|---|

Dimensions of storage rooms:

|

Weather influences:

| |

Fire protection:

|

Fire protection:

| |

Floor condition:

|

Floor condition:

| |

Building permit not required:*

Building permit required:*

|

Building permit partly required:*

|

*Data without guarantee. Please contact your local building authority for further information.

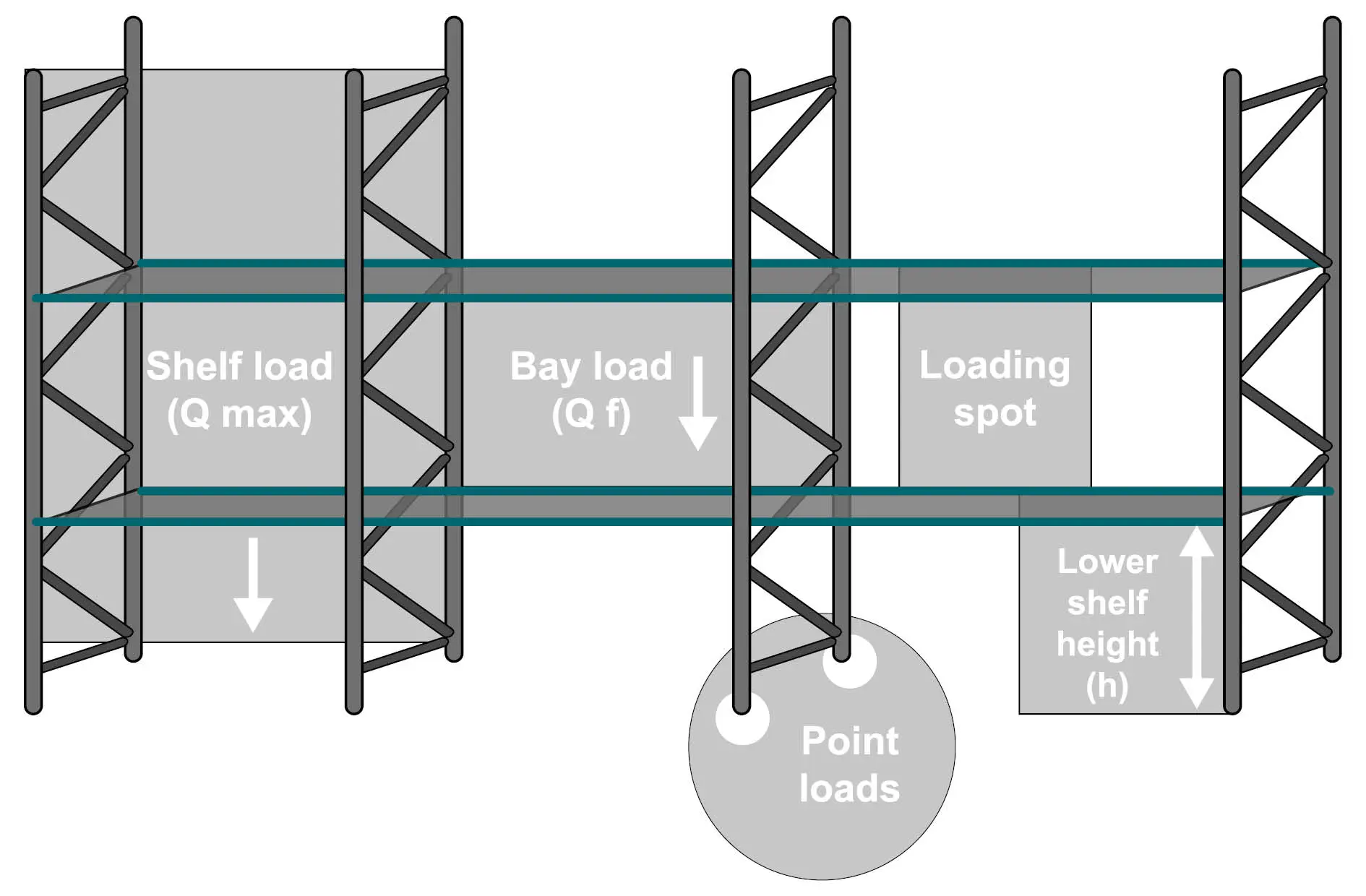

Load capacity, shelf load and bay load

The individual levels of heavy-duty shelving can only be loaded to a limited extent in order not to negatively influence the stability of the shelving or shelving system:

- Load Capacity = Shelf Load (Qf)

- This specification indicates the permissible and load-bearing maximum weight for a single shelf or shelf base under uniform load.

- Load Capacity = Bay Load (Qmax)

- This describes the permissible and load-bearing maximum weight of all shelf levels of a shelf or shelf bay. The dead weight is not included. For stability reasons, the bay load must never be exceeded!

- Point Load

- This describes the load that can be exerted on the floor or a level.

You should take care never to overload industrial shelving units and always to load them correctly. In order to be able to utilise the complete shelf load, we recommend that you distribute heavy goods evenly on the individual shelf levels. Heavy point loads placed in the middle may halve the shelf load due to the bending stress of the shelf.

Weights stored on the floor, on the other hand, are not included in the bay load calculation because they do not influence the statics of a shelving system. At floor storage locations, you can ideally place and arrange pallets and boxes as well as heavy point loads, as long as they do not exceed the lower shelf height (h).

The possible loading of an industrial shelving system can be easily calculated based on the bay and shelf load. If the bay load of your heavy-duty shelving is 2,500kg and the shelf load 250kg, you can theoretically install 10 shelves.

Material of the heavy-duty shelving

The frames of the heavy-duty shelving and racking systems available at Jungheinrich PROFISHOP are mostly made of steel or tubular steel and thus guarantee a long service life and high load capacities. To protect the racking from mechanical or weather-related influences, the metal struts used are usually powder-coated or galvanised.

If you require heavy-duty shelving for particularly demanding or hygienically sensitive areas, we also offer stainless steel models. These models can be safely and thoroughly cleaned or sterilised. They are also ideal for storage in damp or cool rooms – for example in the food industry or in pharmaceutical companies.

Load-bearing capacity or suitability of the subfloor for industrial shelving units

Wherever industrial shelving is to be installed, the load-bearing capacity of the subfloor must be calculated. This is the only way to ensure that the shelving unit can stand safely under full load.

- As a basic principle it should be noted: the floor at the planned racking location must be such that it can bear the dead weight of the racking system, as well as twice the bay load.

- A suitable, load-bearing substrate for a racking system is, for example, concrete: this must have a minimum thickness of 200mm and at least meet the requirements of compressive strength.

It may be necessary to anchor the heavy-duty shelving unit to the floor for safety reasons. Here, each shelving type and location must be assessed individually. To ensure work safety, you should never place heavy-duty shelving on uneven ground, asphalt or interlocking paving stones.

Extendable shelving system

As soon as your product range expands or you want to react flexibly to changes, an extension to the existing shelving system can be a sensible solution. With our wide range of add-on bays for shelving or extension modules, you can combine different advantages and features of shelving types. This allows you to restructure the warehouse in a cost-saving way and increase capacities at the same time.

5. FAQ for industrial shelving

The shelf load is the load that a single shelf or shelf base can carry. The bay load, on the other hand, refers to the maximum weight that may be stored evenly throughout the entire racking bay. To avoid accidents, it is advisable to clearly mark the load and the maximum permissible load with the inspection sticker on the shelves. In any case, we recommend that you take the manufacturer's specifications into account.

Heavy-duty shelving must also be able to carry stored loads of up to several tonnes and at the same time safely withstand the resulting dynamics of sticker trucks and other industrial trucks when being stored and retrieved.

Every employer is responsible for ensuring that accident prevention regulations (UVV) are observed when erecting heavy-duty shelving. Therefore, you should always comply with all guidelines.

Heavy-duty shelving is subject to inspection. For this purpose, specially trained employees carry out and record a weekly visual inspection of each individual rack. The annual inspection of the heavy-duty racking system within the framework of the Ordinance on Industrial Safety and Health is carried out by a certified racking inspector.