Table of contents

Pneumatics refers to the technique in which mechanical movement is generated with the help of pressurised gas. Like hydraulics, pneumatic systems belong to the field of fluid dynamics. However, while hydraulics uses liquids as the working material, pneumatics works with compressed air. Plainly put, pneumatics is a simple and reliable way of making things move just by using clean, dry air.

Using air as a drive medium is cheap and relatively environmentally friendly, and the areas of application are very diverse. This is why compressed air and pneumatic tools are so popular.

What does pneumatics mean?

The word pneumatics is derived from the Greek word pneuma, which translated means ‘wind’ or ‘breath’. It refers to a diverse field of technology in which work is carried out with compressed air or compressed air-driven systems.ystems.

Pneumatics basics

Pneumatics provides movement and drive. Usually, pneumatic cylinders are the first thing associated with this technology, but more specialised and complex systems are also available, such as vacuum systems, grippers, or even air springs which are ideal for damping shocks.

Pneumatic systems, also known as control systems, work with compressed air. In most systems, there is an overpressure of 6 bar. High-pressure systems, which are used for gas pipelines, work with pressure up to 18 bar. However, the highest pressure needed to produce products like plastic bottles is up to 40 bar.

How does pneumatics work?

In basic pneumatic systems, air is compressed and fed via valves to the desired location. The energy stored in the compressed air is then converted into kinetic energy and used in specific ways, for example, to move a cylinder piston in a specific direction.

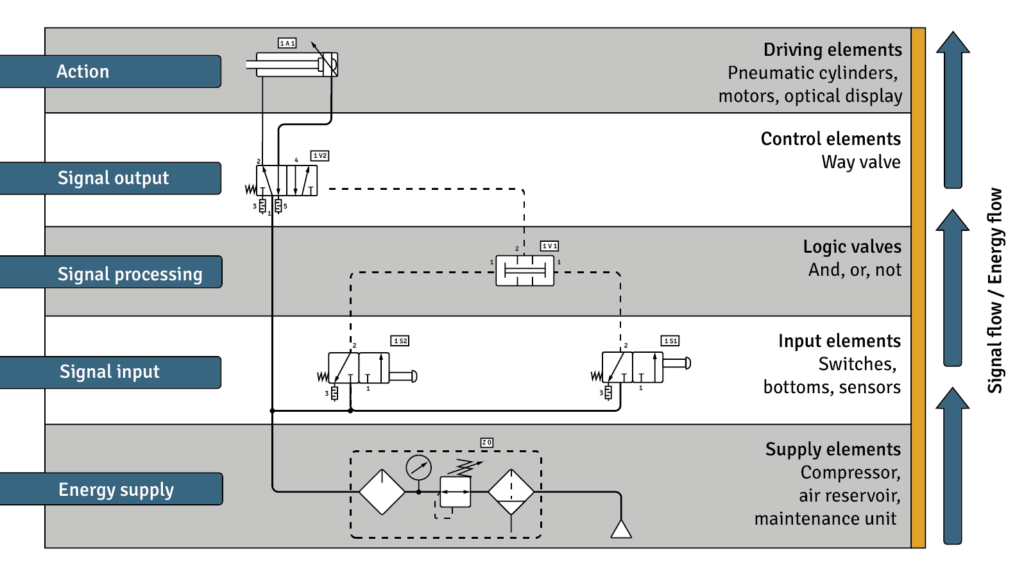

Fundamentally, every pneumatic control system consists of four components:

- Compressed air generation: The required ambient air is drawn in by one or more compressors and then compressed to between 6 and 40 bar depending on requirements. Compressing air generates heat that can also be used as a source of heat energy.

- Compressed air treatment: The compressed air is freed from impurities such as dust or pollen using various filter systems. This is important in ensuring that the pneumatic systems have the longest possible service life.

- Compressed air distribution: Compressed air is distributed via pipes or hoses. To prevent the air from becoming contaminated again, the pipes must be leak-proof and emit as little rust or water as possible. In most cases, storage facilities are also integrated into the pipe networks.

- Application/performance of work: Compressed air is supplied to the respective work processes via valves or actuators. The number of pneumatic switching positions and connections varies depending on the application and the device. The mechanical work is performed with the help of compressed air by so-called working elements – mainly pneumatic cylinders.

Safety standards specify how pneumatic circuits must be constructed for different systems and devices.

Where is pneumatics used?

Pneumatic systems are used in a wide variety of industries and areas, from material handling to robotics and medical technology. Other areas of application are drive systems and transport. For example, systems may be installed in air brakes of trucks or buses or used for air-filled tyres. Pneumatic tube systems can transport smaller unit loads or liquids. Some special pneumatic tools only work with compressed air – for example in spray painting and other surface treatments.

Advantages of pneumatic systems

Pneumatic systems have several advantages. The source material used, namely air, is environmentally friendly, cheap, and available everywhere. Air can be used in any quantity and can also be easily transported over long distances.

Other advantages of pneumatics are:

- Storage capability: Compressed air can be stored in the appropriate pressure vessels.

- Temperature resistance: Compressed air is insensitive to temperature fluctuations.

- Safety: There is no danger of explosion or fire with compressed air.

- Environmental friendliness: Compressed air that escapes does not cause any environmental damage.

- Simple design: This makes low-cost solutions possible.

- Speed: Compressed air is a very fast working medium.

- Easily adjustable forces and speeds: The pressure level can be adjusted to the respective application.

- Force: High forces are attainable in a comparatively small installation space.

- Resistant to overloading

- No additional cooling necessary: The air itself already provides sufficient cooling for the individual drive components.

One possible disadvantage of pneumatics is low efficiency. Even if the heat generated during compression is reused, some energy will be lost. Cold temperatures can also be a problem. When compressed air flows through equipment and machines, it can cool them down considerably and cause ice to build up. Working with pneumatic circuits also generates noise, but this can be reduced by using silencers. Finally, you should consider the limited power of compressed air systems too.

FAQs about pneumatics basics

The biggest difference between pneumatics and hydraulics is that pneumatics uses air to generate pressure whereas hydraulics uses oil or water. Since pneumatics does not require a closed system of pipes for liquids, it is usually less complex in structure. Another difference between the two principles is so-called compressibility, i.e. the property of either being compressible or not compressible. Gases are compressible, liquids are not. This results in both systems having certain advantages and disadvantages.

Hydraulics can be precisely controlled and can generate very large forces. However, hydraulic oils are expensive and can cause environmental hazards in the event of a leak. Pneumatics is somewhat less precisely controllable due to the compressibility of gases, exhibits heat energy losses, and requires larger cylinder surfaces to generate the force of a smaller hydraulic system. Air is free as well as freely available and not harmful to the environment.

Pneumatics is mainly used in four areas of application: for drive systems, spraying, transport and testing procedures. Pneumatic drives perform linear and rotary movements. Pneumatic tools and devices include pneumatic hammers, pneumatic drills, sanders and grinding machines, paint and varnish spraying systems, pneumatic tube systems and pneumatic brakes.

While pneumatic systems excel at regulating forces, regulating positions is more difficult. Unlike liquids, which expand uniformly, gases compress under pressure. Another limitation is energy efficiency – compressing air always results in some energy loss, as the process generates heat. Although this heat can be captured and used for heating purposes, it’s often not specifically harnessed and thus wasted.

Moreover, there is a risk that excessive friction will generate such high temperatures locally that explosions may occur, or heavily loaded components may wear out faster. In general, pneumatic system drives wear out faster and require more regular maintenance. Additionally, pneumatic systems can’t produce as much force as hydraulic systems. This is because hydraulic systems use liquids, which can’t be compressed. These incompressible liquids allow for power to be transferred with very little energy loss, making hydraulic systems more efficient at generating force.

Image source:

© gettyimages.de – Denys Yelmanov